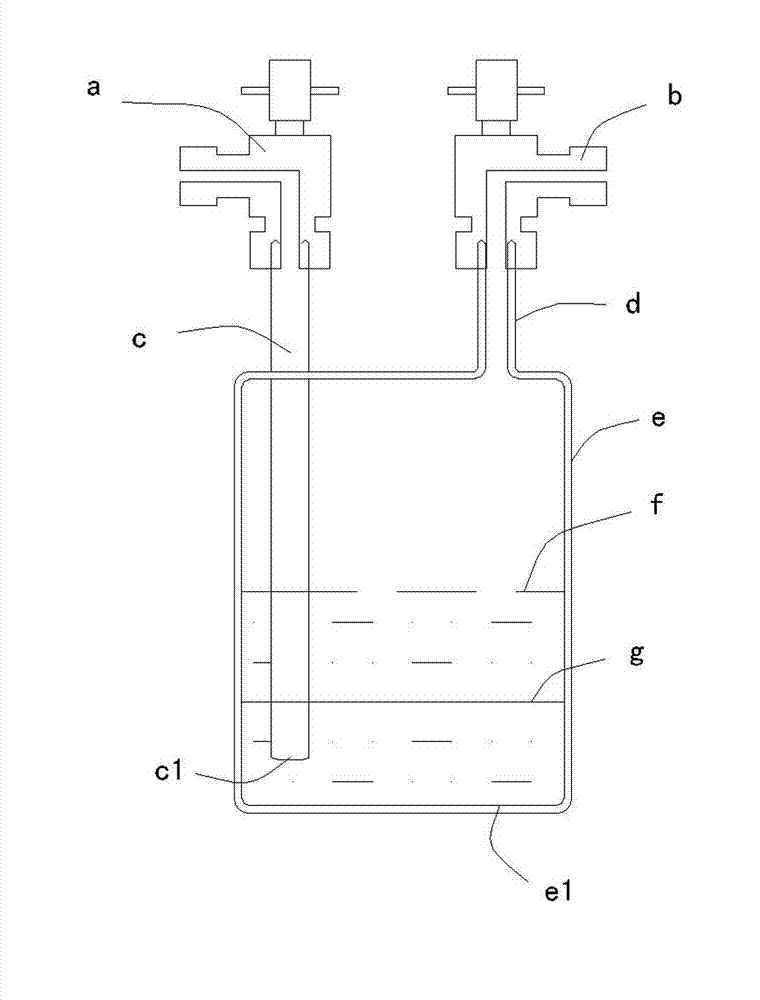

Silica source flask

A source bottle and quartz technology, applied in the field of quartz source bottle, can solve the problems of non-reusability, high price, waste, etc., and achieve the effects of stable saturated concentration, improved concentration uniformity, and longer working stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

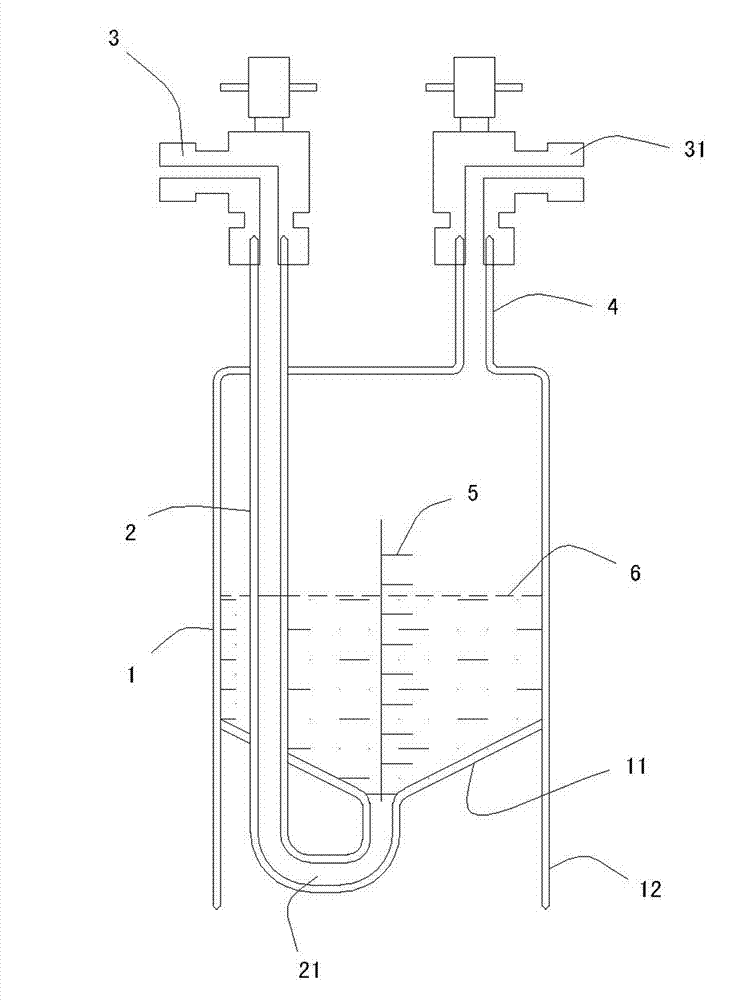

[0014] see figure 2 . The source bottle body 1 is in a circular cylindrical shape, and its upper structure is basically consistent with the prior art. It is provided with an air inlet pipe 2 and an air outlet pipe 4. The upper ports of the air inlet pipe 2 and the air outlet pipe 4 are respectively sealed and connected to the air intake control valve. 3. Air outlet control valve 31. Among them, the gas outlet control valve 31 can be selected as a one-way gas outlet control valve to avoid backflow of gas and endanger equipment and operators.

[0015] The key innovation of the present invention lies in the position below the liquid level 6 . From figure 2 It can be seen in the figure that after the inlet pipe 2 made of quartz glass passes through the bottom wall 11 of the funnel, a U-shaped bend 21 is formed, and the bottom of the U-shaped bend 21 is lower than the outlet of the bottom wall 11 of the funnel. The U-shaped bend 21 turns back and communicates with the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com