Production system and production method of aluminum alloy billet and aluminum alloy billet

A production system, aluminum alloy technology, applied in general control system, control/adjustment system, transportation and packaging, etc., can solve the problems of management and manufacturing process feedback without manufacturing and inspection information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

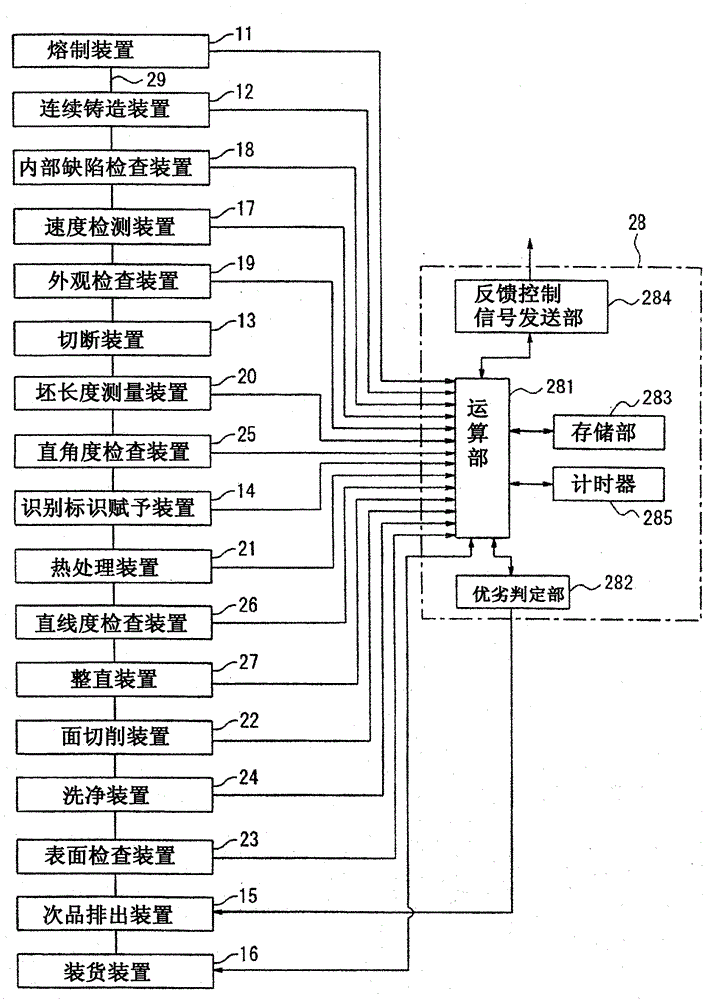

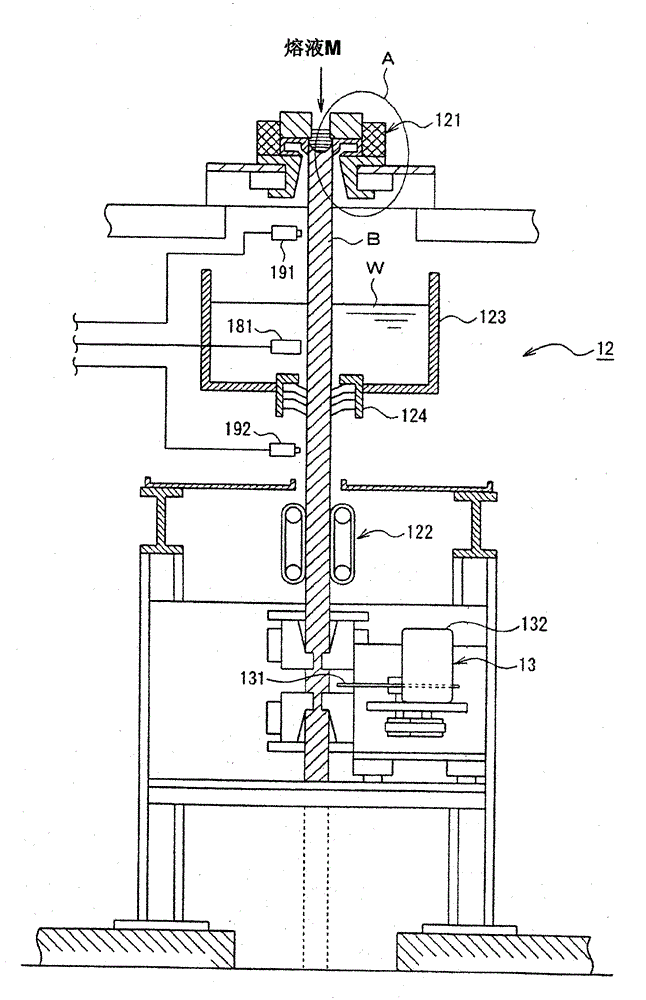

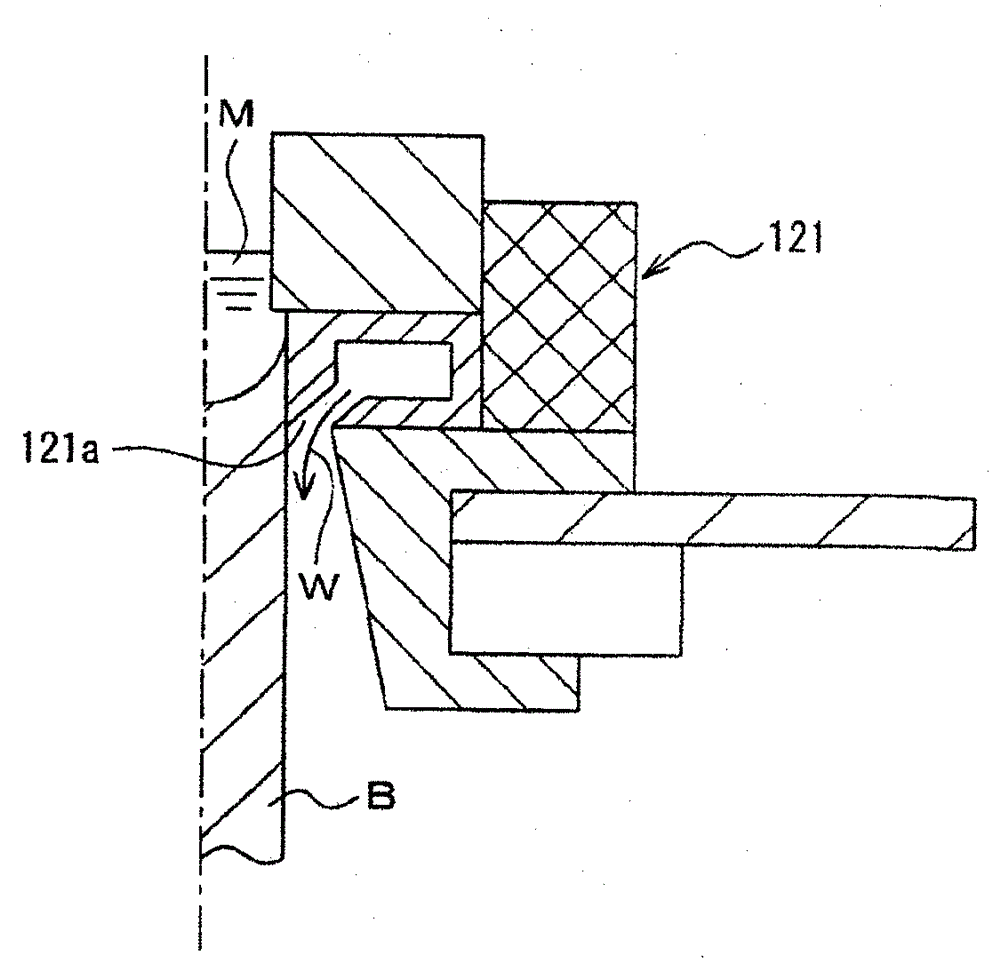

[0056] figure 1 is a drawing schematically showing a schematic configuration of an aluminum alloy billet production system according to an embodiment of the present invention, figure 2 yes means figure 1 A longitudinal sectional view of an example of the continuous casting apparatus shown, image 3 is an expanded representation figure 2 The drawings showing the structure of Part A, as figure 1 As shown, the production system of an aluminum alloy billet according to an embodiment of the present invention includes: a melting device 11, a continuous casting device 12, a cutting device 13, an identification marking device 14, a defective product discharge device 15, a loading device 16, a speed Inspection device 17, internal defect inspection device 18, appearance inspection device 19, billet length measurement device, heat treatment device 21, surface cutting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com