Water grinding head for diamond dust-free pump

A water grinding head and diamond technology, applied in metal processing equipment, parts of grinding machine tools, grinding/polishing equipment, etc., can solve the problems of reducing the service life of grinding heads, affecting the grinding effect, waste of resources, etc., to avoid falling off , The effect of improving grinding efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the utility model is further described:

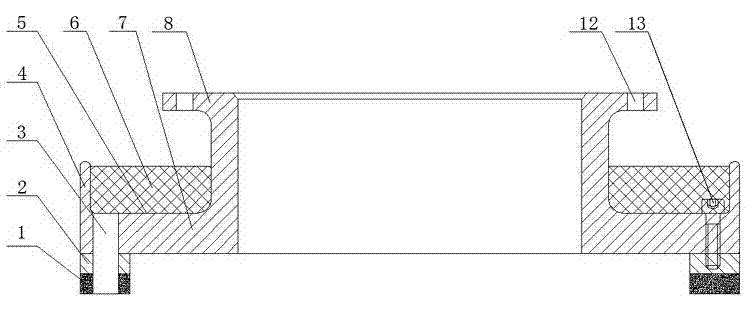

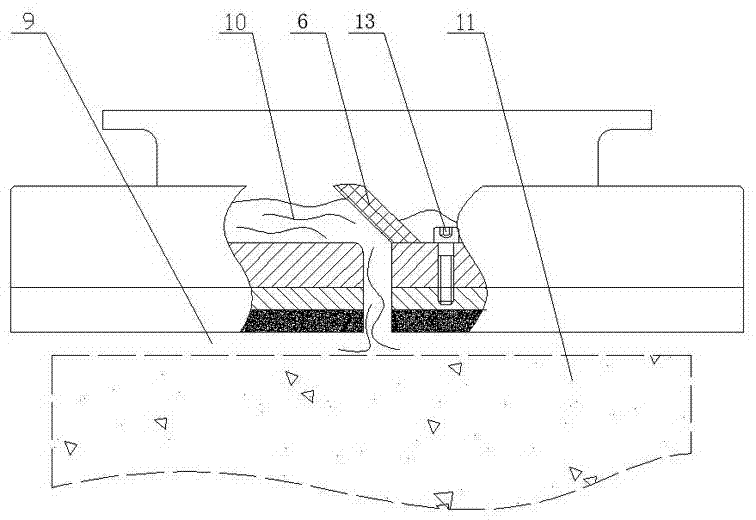

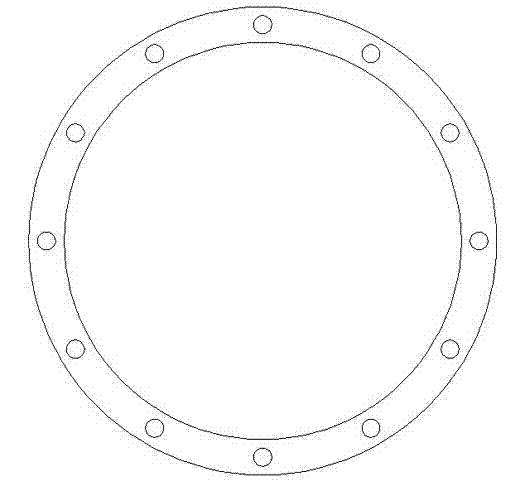

[0012] A diamond dust-free pump water grinding head, comprising: a grinding disc with a shaft hole in the center and a diamond integral grinding ring fixed on the grinding disc and coaxial with the grinding disc, and the two ends of the grinding disc are respectively provided with small flanges 8 and large flanges. The blue plate 7, the upper circumference of the small flange 8 is evenly provided with locking holes 12, the upper circumference of the large flange is evenly provided with assembly bolts 13 and water supply holes 3, and the annular groove plate 4 provided on the edge and the grinding disc form a storage A water tank 5, the water storage tank 5 is provided with pumping blades 6 matched with the water supply holes 3, and the diamond integral grinding ring 1 is installed on the large flange 7 through the assembly bolts 13.

[0013] As a preferred solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com