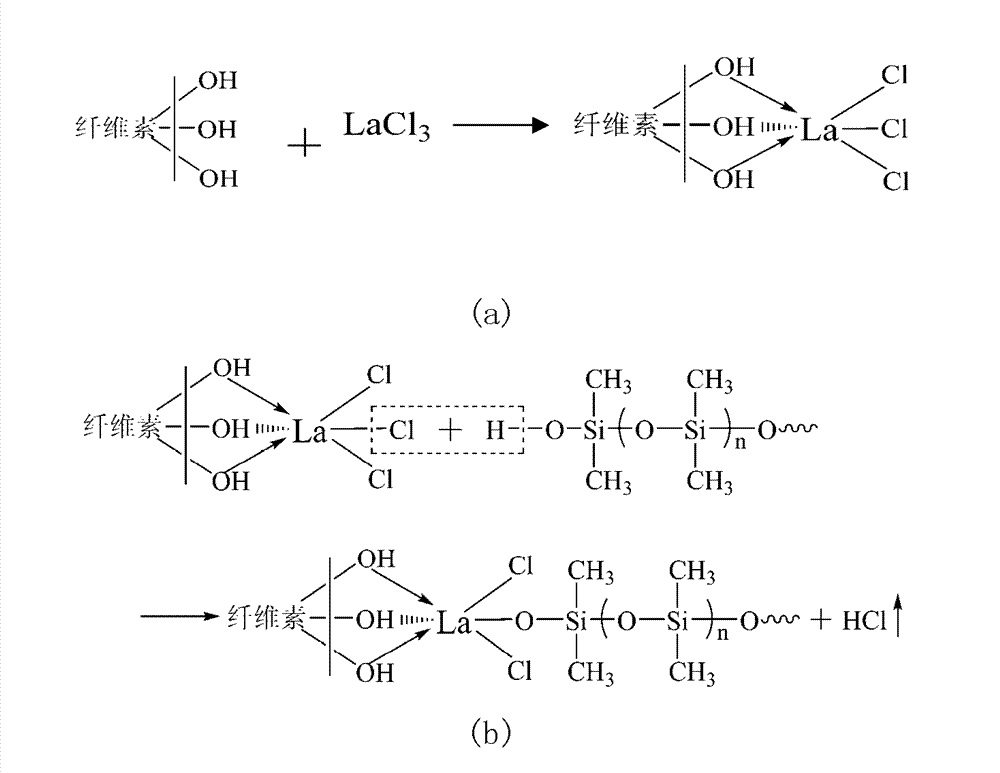

Rare earth silicone oil modified jute fiber/polypropylene or polypropylene alloy compound material and preparation method thereof

A composite material, polypropylene technology, used in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problem of fiber modification treatment effect to be improved, unstable hemp fiber/polymer material properties, and poor polymer interface compatibility and other problems, to achieve the effect of solving unstable performance, excellent mechanical properties and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

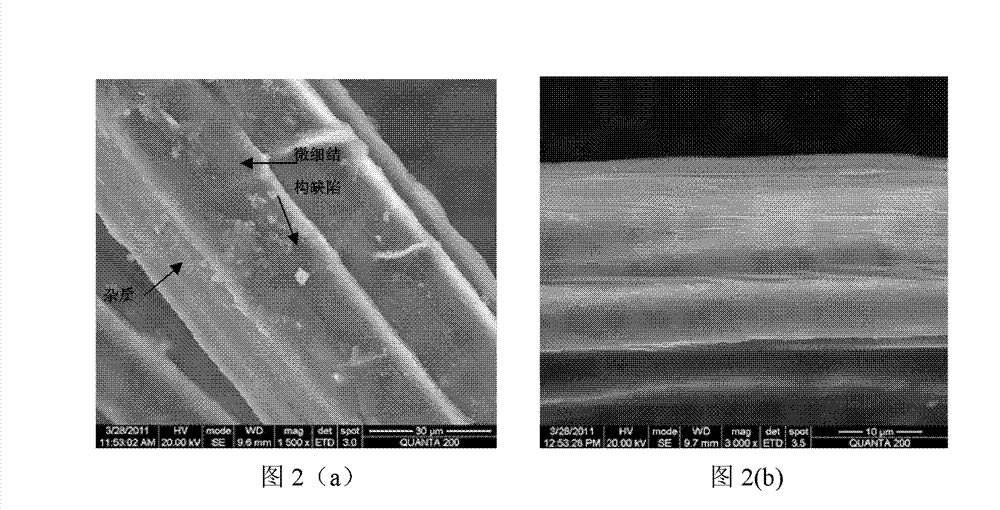

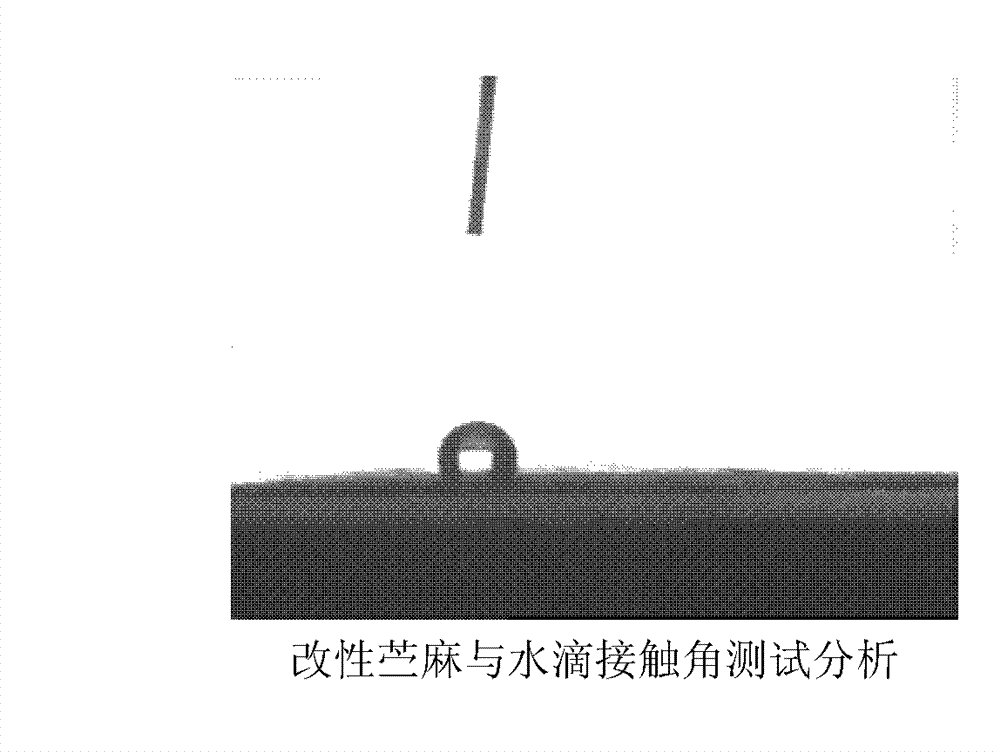

Method used

Image

Examples

Embodiment 1

[0057] 1. Weigh 4.3g of lanthanum chloride (containing 6 crystalline waters), and dissolve the weighed lanthanum chloride into 1500ml of water under medium-speed magnetic stirring until it is completely dissolved;

[0058] 2. Weigh 100g of ramie fiber rinsed with water and dried, put it into the prepared rare earth lanthanum chloride solution, soak it with ultrasonic vibration at 60°C for 1 hour, remove it, and dry it;

[0059] 3. While treating the hemp fiber with the rare earth lanthanum chloride solution, mix the amino silicone oil emulsifier (OP-10) and the dispersant (cetyl alcohol) in a ratio of 6:6:1, and strengthen the ultrasonic vibration at 60°C Vigorously stir for 1 hour, and configure 500ml silicone oil emulsion.

[0060] 4. Put the ramie fiber treated with rare earth lanthanum chloride into the prepared amino silicone oil emulsion, and add distilled water to 1500ml. Ultrasonic vibration reaction was performed at 80°C for 3 hours (3hr). After the reaction was comp...

Embodiment 2

[0065] 1. Weigh 2.15g of lanthanum chloride, and dissolve the weighed lanthanum chloride into 1500ml of water under medium-speed magnetic stirring until it is completely dissolved;

[0066] 2. Weigh 100g of ramie fiber rinsed with water and dried, put it into the prepared rare earth solution, soak it with ultrasonic vibration at 60°C for 1 hour, remove it and dry it;

[0067] 3. While treating the hemp fiber with the rare earth lanthanum chloride solution, mix the amino silicone oil emulsifier (OP-10) and the dispersant (cetyl alcohol) in a ratio of 5:5:1, and strengthen the ultrasonic vibration at 60°C Vigorously stir for 1 hour, and configure 500ml silicone oil emulsion.

[0068] 4. Put the ramie fiber treated with rare earth lanthanum chloride into the prepared amino silicone oil emulsion, and add distilled water to 1500ml. Ultrasonic vibration reaction was performed at 80°C for 2 hours (2hr). After the reaction was completed, the treated ramie was air-dried or dried in a ...

Embodiment 3

[0073] 1. Weigh 8.6g of lanthanum chloride (containing 6 crystal waters), dissolve the weighed lanthanum chloride into 1500ml of water under medium-speed magnetic stirring and continue stirring until completely dissolved;

[0074] 2. Weigh 100g of ramie fiber rinsed with water and dried, put it into the prepared rare earth lanthanum chloride solution, soak it with ultrasonic vibration at 60°C for 1 hour, remove it, and dry it;

[0075]3. While treating hemp fiber with rare earth lanthanum chloride solution, mix amino silicone oil emulsifier (OP-10) and dispersant (cetyl alcohol) in a ratio of 5:5:1, and strengthen it by ultrasonic vibration at 60°C Vigorously stir for 1 hour, and configure 500ml silicone oil emulsion.

[0076] 4. Put the ramie fiber treated with rare earth lanthanum chloride into the prepared amino silicone oil emulsion, and add distilled water to 1500ml. Ultrasonic vibration reaction was performed at 80°C for 3 hours (3hr). After the reaction was completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com