Whole quenching device of circular track

An integral quenching and circular track technology, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of uneven quenching layer depth and hardness, long quenching time, and inconsistent heating deformation, and achieve small quenching deformation and improve production efficiency. , the effect of uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

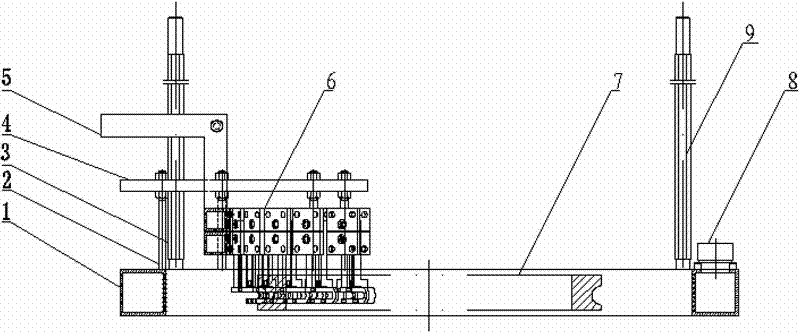

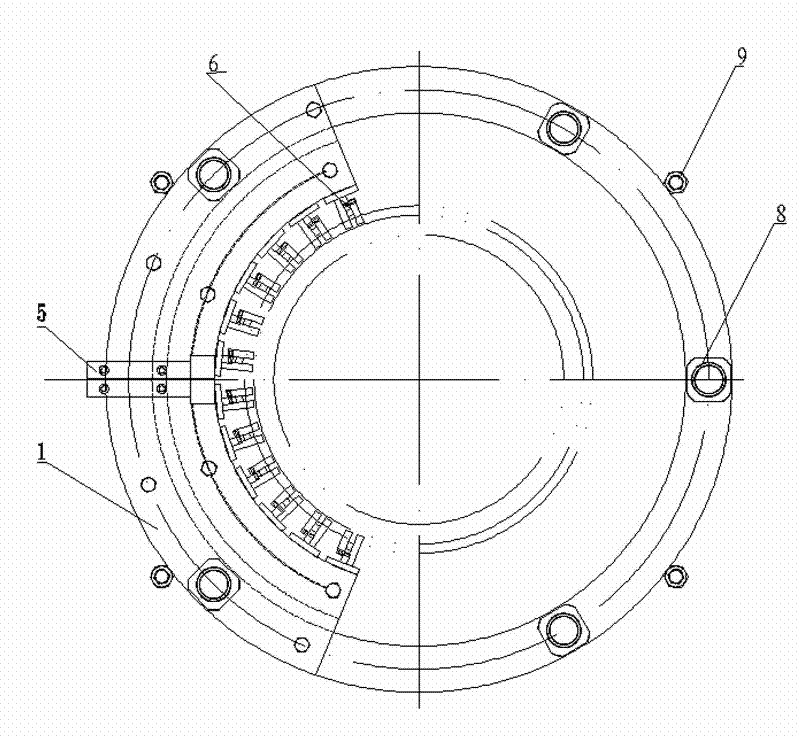

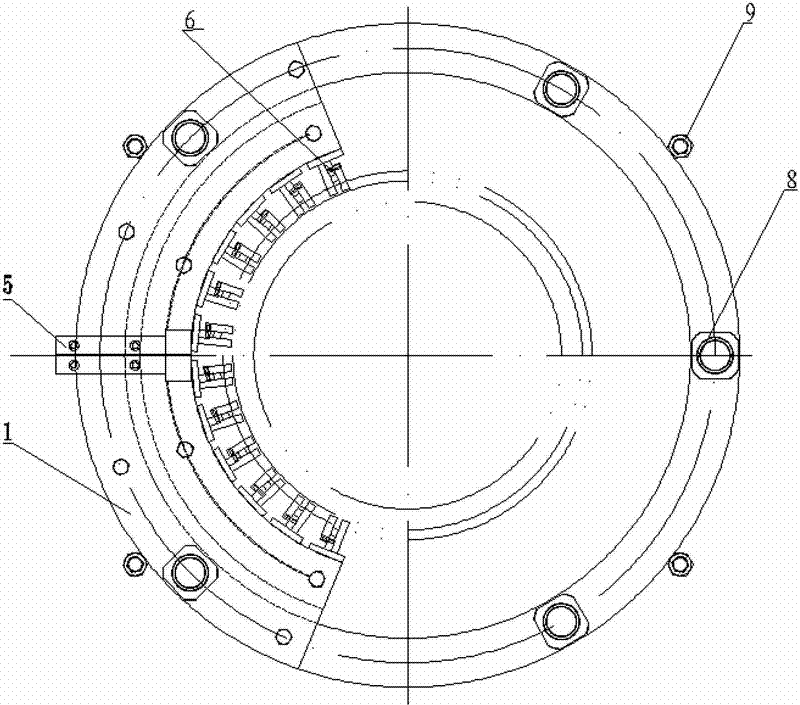

[0010] combine figure 1 , 2 As shown, the present invention is described as follows: a ring-shaped track overall quenching device, including a liquid sprayer 1, a track sensor, the liquid sprayer 1 is a ring body, and the ring body is a hollow cavity, and the liquid sprayer 1 is Connected with a liquid inlet joint 8 and a connecting screw 9, the track sensor is installed in the inner ring cavity of the liquid sprayer, and the inner ring of the liquid sprayer 1 is provided with a liquid spray hole on the 360° circle; the track sensor is formed along the circumference At least 5 orbital induction coils 6 are evenly arranged on the top, and at least 5 orbital induction coils 6 are installed on a fixed block 4, and the fixed block 4 is fixed on the liquid sprayer 1 by bolts 2. The orbital induction coils 6 are connected to each other, and one end A liquid inlet is provided, and a liquid outlet is provided at the other end, and the common pole plate 5 is installed on the fixed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com