Device and method for monitoring and controlling safety risk of steam turbine generator bearing on line

A turbo-generator, safety risk technology, applied in safety devices, engine components, machines/engines, etc., can solve the problem of online monitoring and control without the safety risk of turbo-generator bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

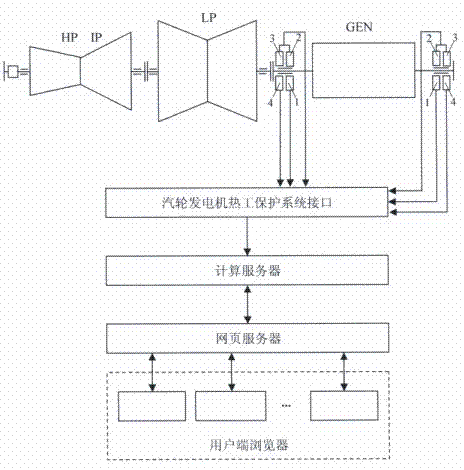

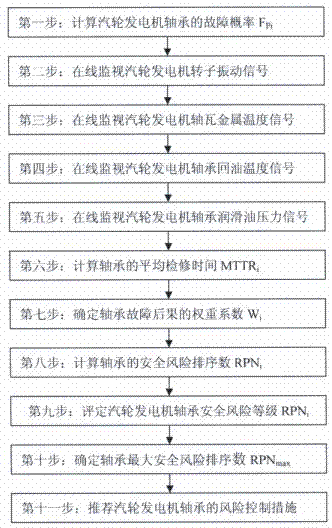

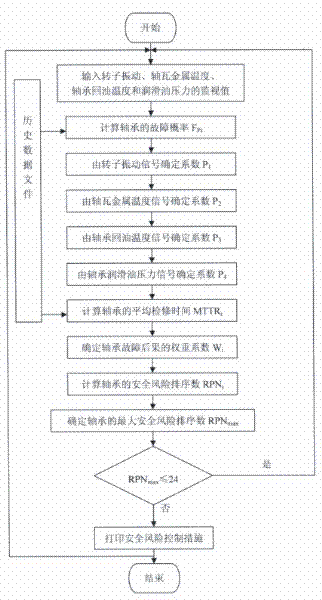

[0048] Such as figure 1As shown, the block diagram of the online monitoring and control method for the safety risk of the steam turbine generator bearing of the present invention, the online monitoring and control device for the safety risk of the steam turbine generator bearing of the present invention consists of a vibration sensor 1, a bearing bush metal temperature sensor 2, a bearing return oil temperature Sensor 3, bearing lubricating oil pressure sensor 4, steam turbine generator thermal protection system interface, calculation server, web server and client browser, the turbine side bearing and the exciter side bearing of the generator are respectively equipped with two The vibration sensor 1, a bearing bush metal temperature sensor 2, a bearing oil return temperature sensor 3 and a bearing lubricating oil pressure sensor 4 installed at a 45° horizontal plane, vibration sensor 1, bearing bush metal temperature sensor 2, and bearing oil return temperature sensor 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com