Polypropylene composition for outdoor communication cabinet

A polypropylene composition and communication cabinet technology, applied in the field of polymer materials, can solve the problems of poor weather resistance of polypropylene, brittleness of flame retardant polypropylene, etc., and achieve small creep, good heat resistance and low temperature resistance, The effect of good process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

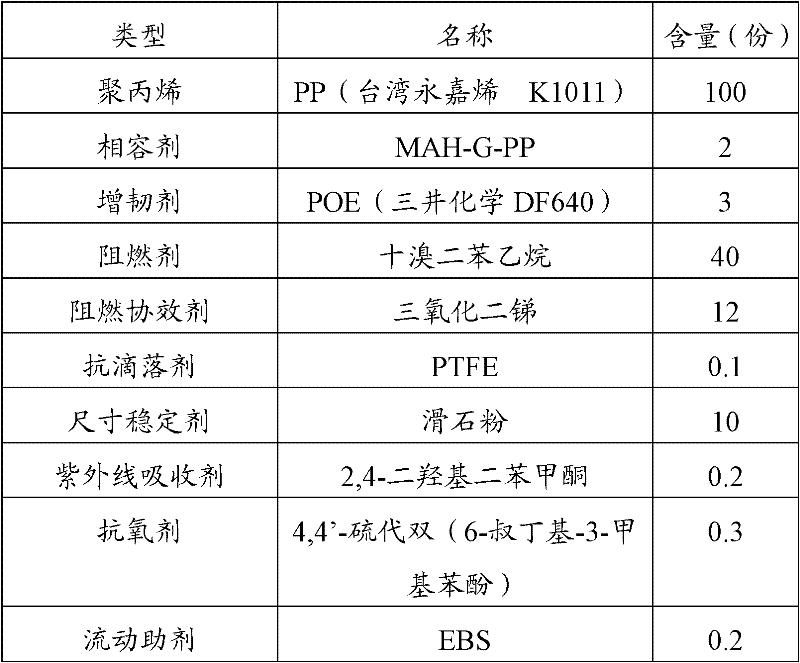

[0029] The composition ratio of the following table is prepared (1 part=100 grams):

[0030]

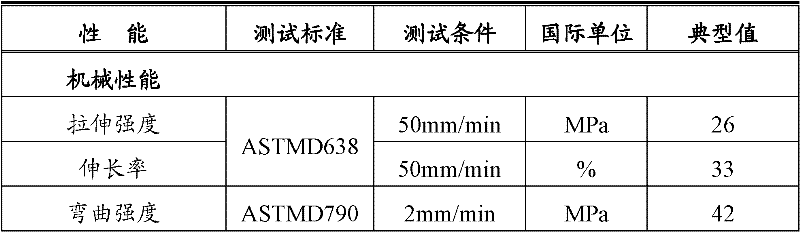

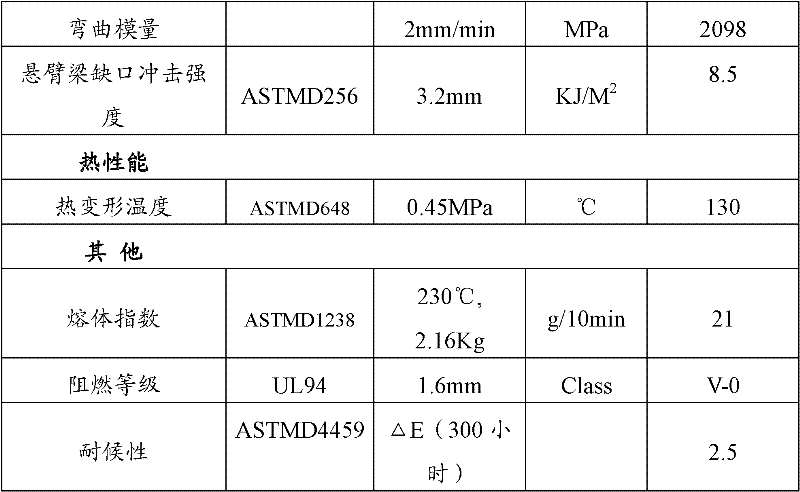

[0031] Performance test results:

[0032] The components are uniformly mixed and then extruded and granulated to obtain the polypropylene composition for outdoor communication cabinets. In this example, a mixer is used for mixing, a twin-screw extruder is used for extrusion, the screw speed is 40r / min, the temperature of the first zone of the extruder head is 185°C, the temperature of the second zone is 200°C, and the temperature of the third zone 200°C, 200°C for zone 4, and 200°C for zone 5.

[0033]

[0034]

Embodiment 2

[0036] The composition ratio of the following table is prepared (1 part=100 grams):

[0037]

[0038] The components are uniformly mixed and then extruded and granulated to obtain the polypropylene composition for outdoor communication cabinets. In this example, a mixer is used for mixing, a twin-screw extruder is used for extrusion, the screw speed is 40r / min, the temperature of the first zone of the extruder head is 185°C, the temperature of the second zone is 200°C, and the temperature of the third zone 200°C, 200°C for zone 4, and 200°C for zone 5.

[0039] Performance test results:

[0040]

Embodiment 3

[0042] The composition ratio of the following table is prepared (1 part=100 grams):

[0043]

[0044]

[0045] The components are uniformly mixed and then extruded and granulated to obtain the polypropylene composition for outdoor communication cabinets. In this example, a mixer is used for mixing, a twin-screw extruder is used for extrusion, the screw speed is 40r / min, the temperature of the first zone of the extruder head is 183°C, the temperature of the second zone is 196°C, and the temperature of the third zone It is 204°C, the temperature in the fourth zone is 201°C, and the temperature in the fifth zone is 200°C.

[0046] Performance test results:

[0047]

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com