Buffer relief valve for hydraulic motor

A technology of hydraulic motor and relief valve, used in servo motor components, fluid pressure actuation devices, mechanical equipment, etc., can solve the vibration and noise of hydraulic system and components, damage, can not better protect the service life of hydraulic components, etc. problems, to achieve the effect of smooth startup, protection of system safety, and improvement of operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

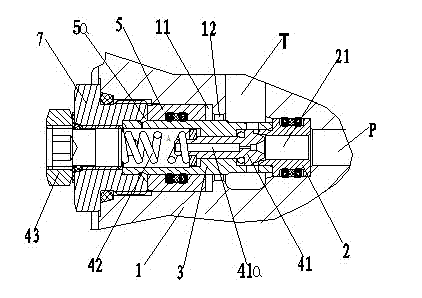

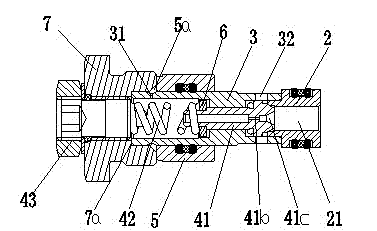

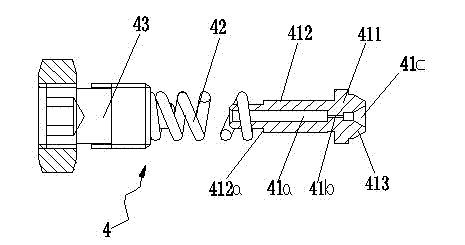

[0019] Figure 1 to Figure 4 Shown is the structural representation of the present invention.

[0020] The reference signs are: oil inlet P, oil return port T, valve body 1, slide chamber 11, oil passage 12, valve seat 2, connection hole 21, valve sleeve 3, fluid chamber 3a, slide rod guide hole 3b , compression chamber 3c, radial damping hole 31, oil outlet hole 32, spool assembly 4, spool 41, axial through hole 41a, first damping hole 41b, tapered hole 41c, valve head 411, valve stem 412, convex Table top 412a, sealing ball head 413, compression spring 42, adjustment bolt 43, buffer piston 5, buffer cavity 5a, pressure pad 6, screw plug 7, reaming table top 7a.

[0021] Such as Figure 1 to Figure 4 As shown, a buffer relief valve for a hydraulic motor of the present invention includes a matched valve body 1, a valve seat 2, a valve sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com