Air-cooled liquid-cooled combined radiating device

A heat dissipation device and combined technology, which is applied to the cooling/heating device of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of short life, large size, and high quality, so as to reduce the bearing strength and ensure Cooling effect, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

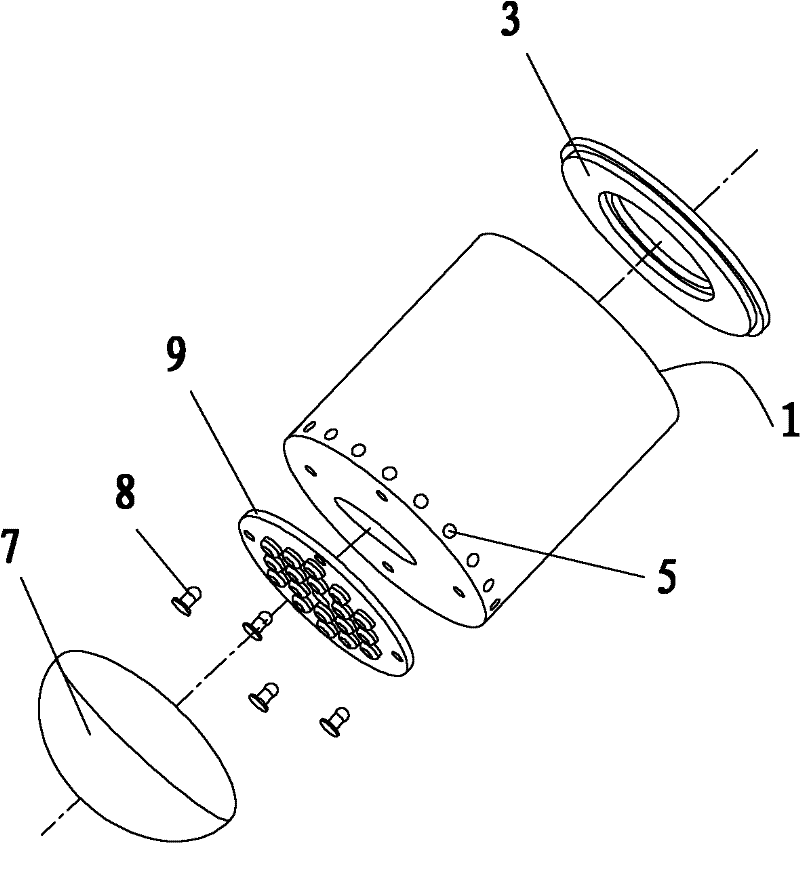

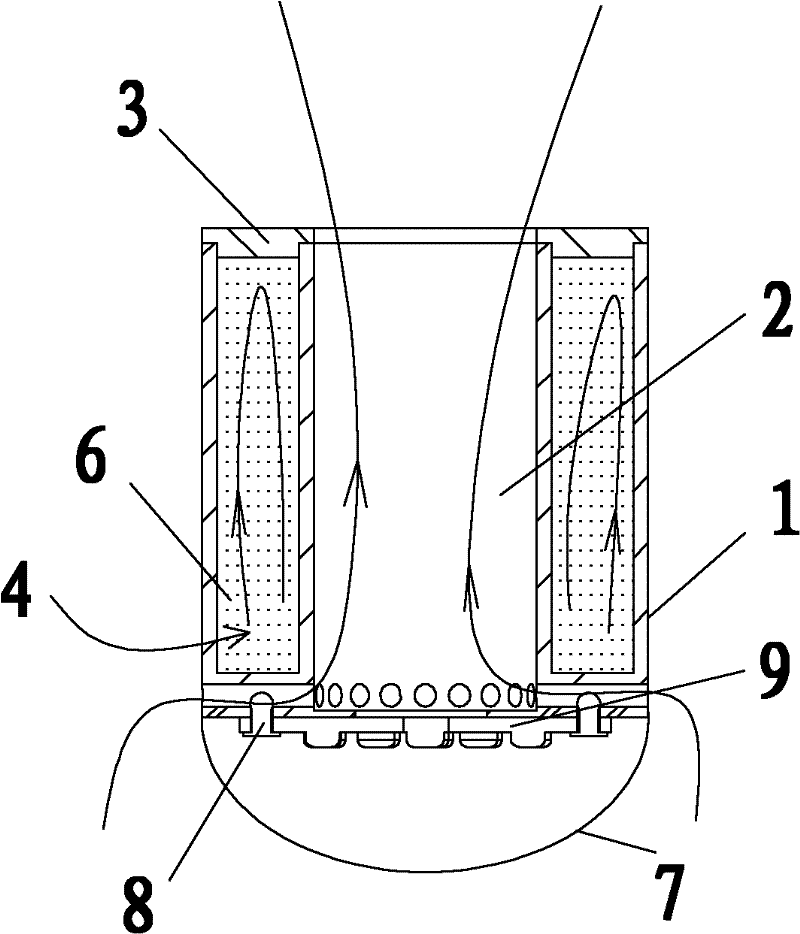

[0022] Such as figure 1 , figure 2 As shown, an air-cooled and liquid-cooled combined heat dissipation device described in this embodiment includes a housing 1 having a surface capable of connecting with a heating element. Sandwich structure, the outer heat dissipation chamber 4 contains heat dissipation fluid 6, the inner heat dissipation chamber 2 has an open airflow channel communicating with the outside world, and a sealing cover 3 covers the outer heat dissipation chamber 4. The housing 1 is a hollow cylinder, and the hollow part is the inner heat dissipation cavity 2 . A plurality of air guide holes 5 are opened below the side wall of the housing 1 to form the inlets of the air flow passages and the air guide holes 5 are evenly distributed in the circumferential direction, and the outlets of the air flow passages are arranged on the upper surface of the housing 1 . The sealing cover 3 has a hollow ring structure and is stepped, and the stepped surface is in conflict w...

Embodiment 2

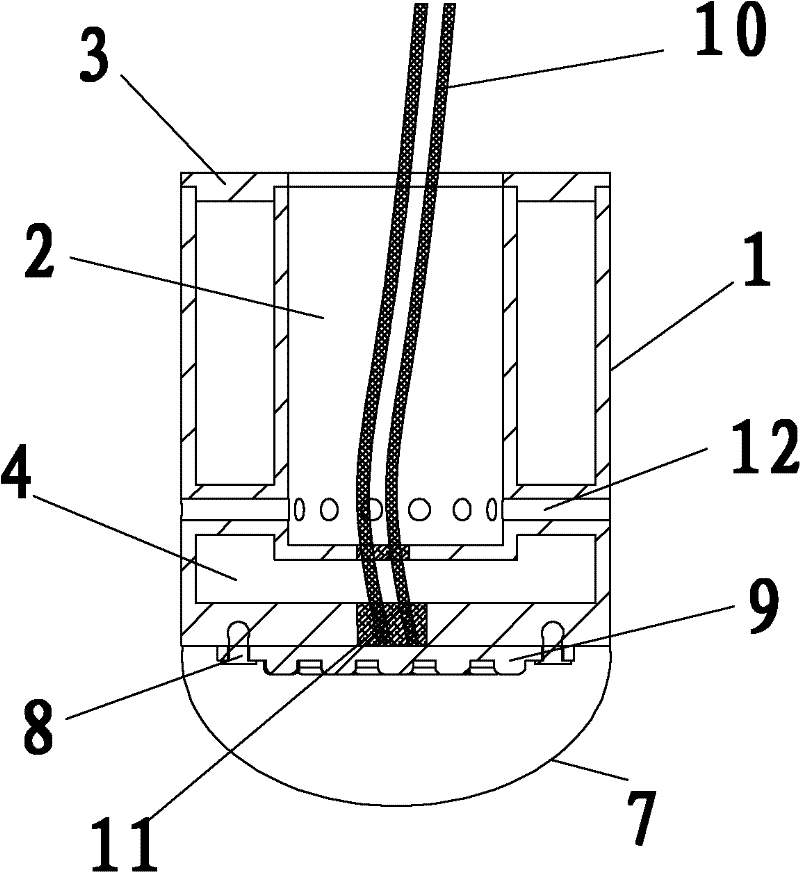

[0026] Such as Figure 4 , Figure 5 As shown, in the air-cooled and liquid-cooled combined heat dissipation device described in this embodiment, the outer heat dissipation cavity 4 is a hollow rectangular cavity, and the sealing cover 3 has a hole in the middle and is stepped. The surface is fastened to the open end of the outer heat dissipation chamber 4. The entrance of the inner heat dissipation chamber 2 is formed by an air guide groove, which is arranged on the connecting surface of the shell 1 and the heating element. This structure is suitable for heat sinks that do not prevent gas from flowing through the bottom of the housing 1 . As shown in the figure, the present invention can connect the LED substrate 9 with the rivet 8 on the lower surface of the casing 1, and then put the lampshade 7 on it. Both the LED substrate 9 and the lampshade 7 are provided with air-conducting through holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com