Sintering furnace for powder metallurgy products

A powder metallurgy and sintering furnace technology, applied in furnaces, furnace types, reducing gas emissions, etc., can solve problems such as unsafe use, human injury, large footprint, etc., to prevent product decarbonization, safe and reliable use, and prevent The effect of product oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

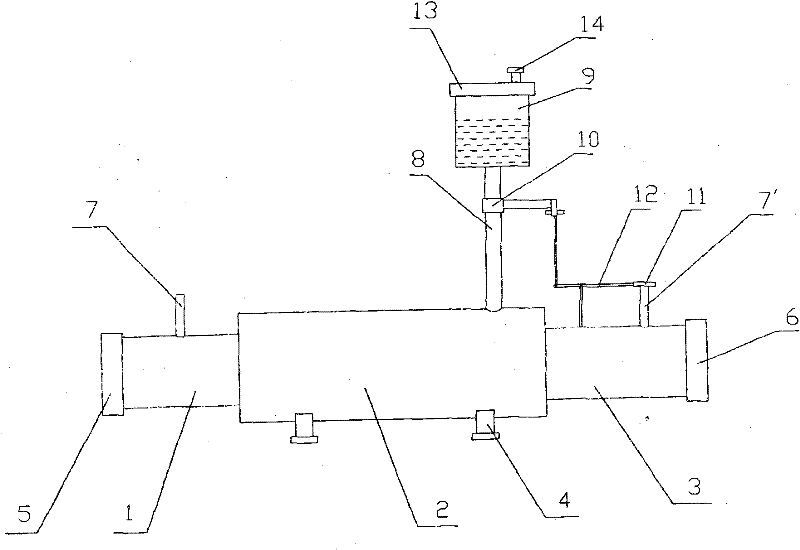

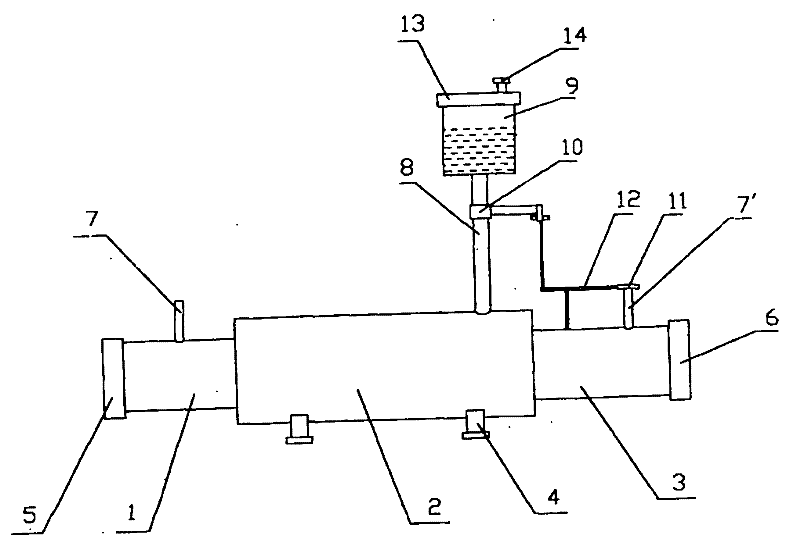

[0007] The present invention consists of a sintering furnace for powder metallurgy products with methanol decomposition protection atmosphere, a sintering furnace feeding section 1, a sintering furnace sintering section 2, a sintering furnace cooling section 3 and a bracket 4, and the front end of the sintering furnace sintering section 2 is connected to the sintering furnace feeder. Material section 1, a feed port cover 5 is provided at the end of the sintering furnace feeding section 1, a sintering furnace cooling section 3 is connected to the rear end of the sintering furnace sintering section 2, and a discharge port is provided at the end of the sintering furnace cooling section 3 The mouth cover 6 and the bracket 4 are fixed on the bottom of the sintering section 2 of the sintering furnace, and the front and rear exhaust pipes 7 and 7' are respectively arranged on the feeding section 1 of the sintering furnace and the cooling section 3 of the sintering furnace. The upper w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com