Plasma method for disposing of waste material, and apparatus therefor

A technology of waste and equipment, applied in the field of waste material treatment, to prevent the formation of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

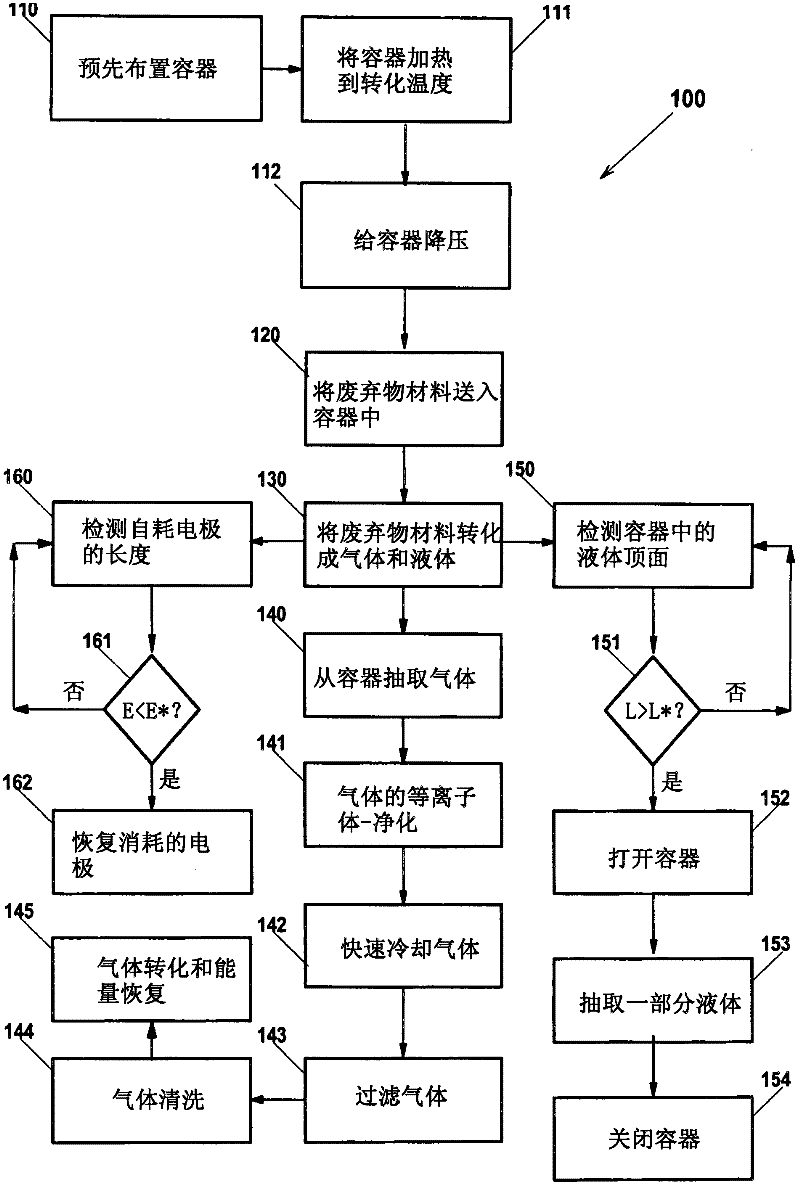

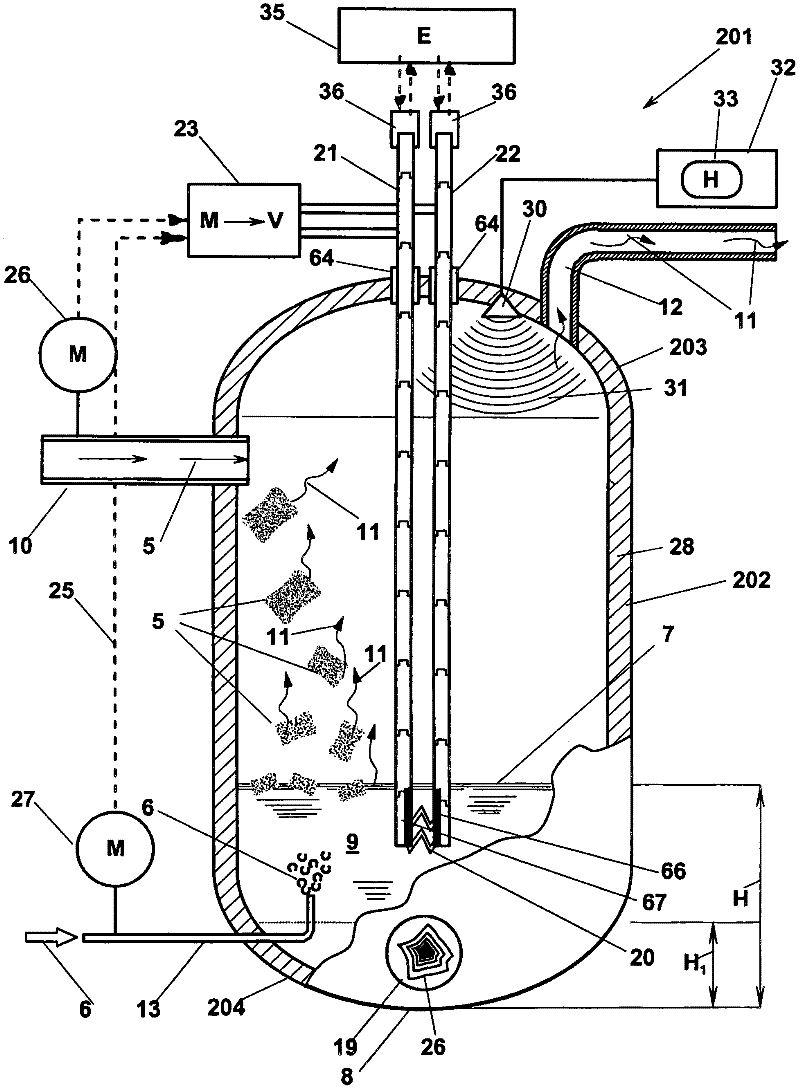

[0090] refer to figure 1 is a flow chart depicting a method 100 for converting waste materials according to the present invention. The method 100 comprises a step 110 of pre-arranging the vessel, a step 111 of heating the vessel to a transition temperature typically set between 1600°C and 2000°C and a step 112 of depressurizing the vessel to an absolute pressure, preferably set at 1 millibar Between to 10 millibars, and most preferably around 4 millibars. The depressurization step 112 is followed by the step 120 of sending the waste material into the container; step 120 is implemented in such a way as to prevent air from entering the container with the waste material, which would cause a loss of vacuum and a portion of the vacuum. Waste material burning. The conversion temperature is high enough to cause and maintain a step 130 in which the waste material is converted into two fractions, an ionized gas 11 (i.e., plasma) and a substantially liquid fraction 9 which accumulates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com