Method of manufacturing lamp and quartz bulb

一种制造方法、真空管的技术,应用在石英真空管领域,能够解决材料费增大等问题,达到降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, a method of manufacturing an ultra-high pressure mercury lamp 1 with a rating of 150W will be described.

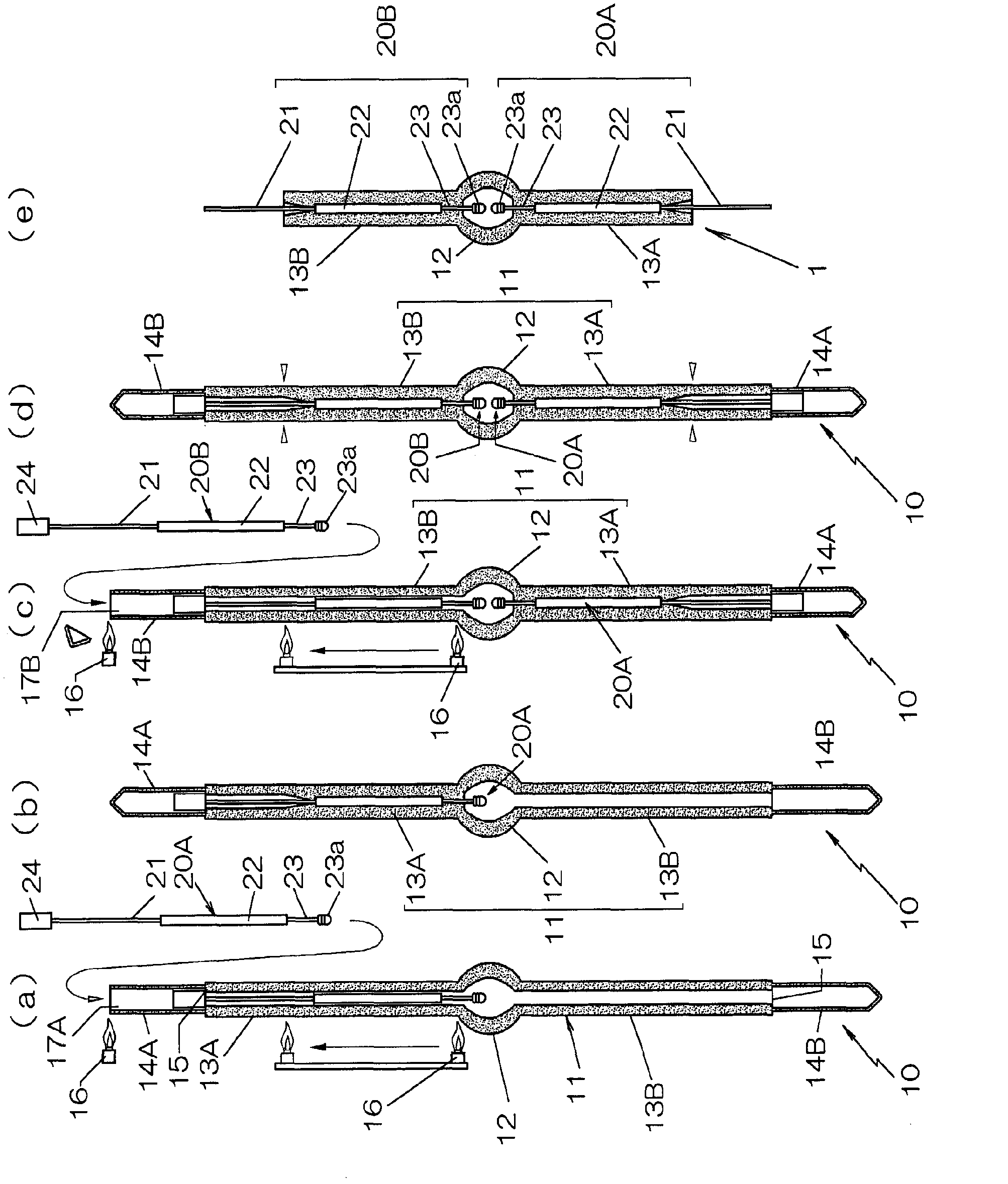

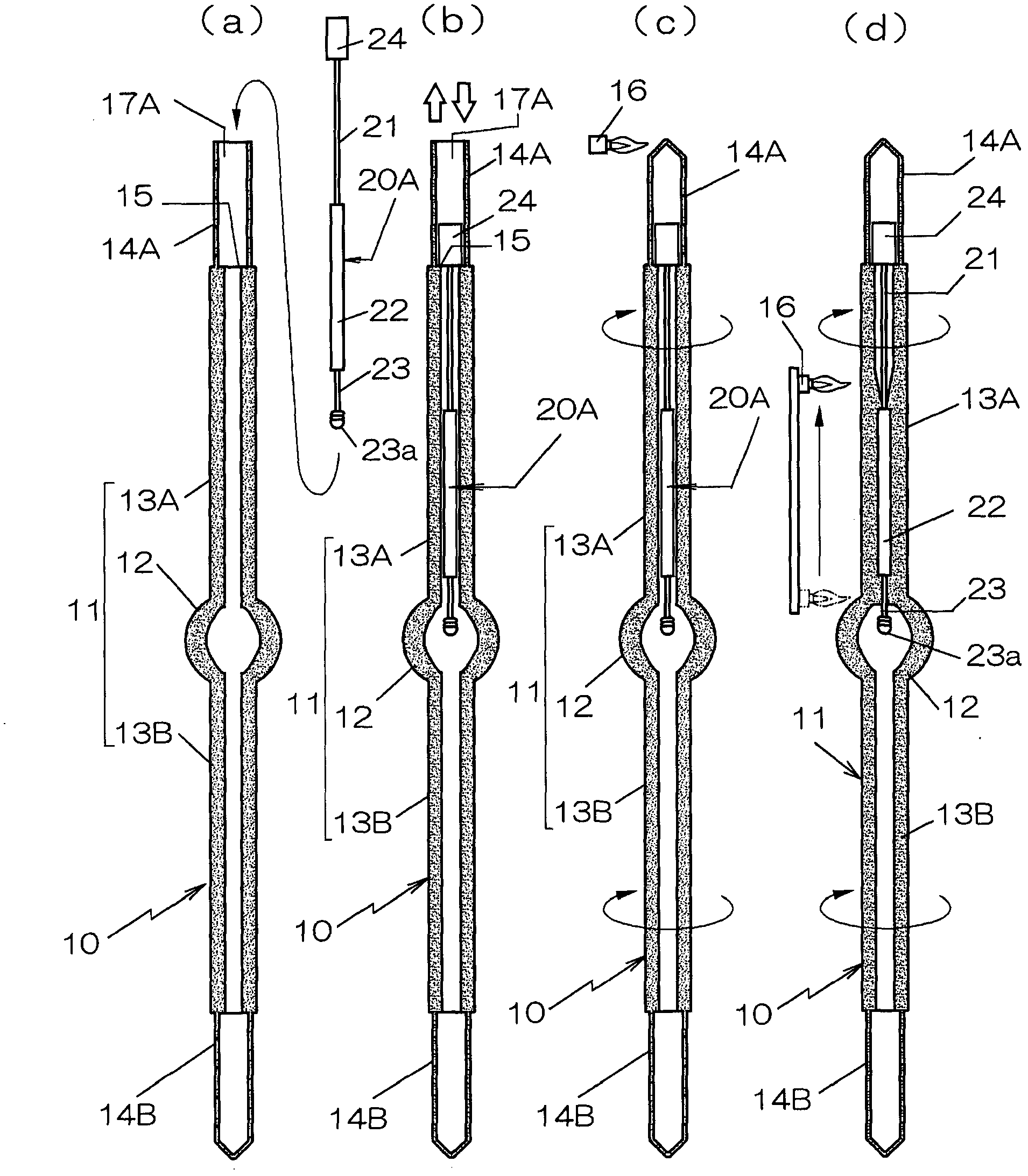

[0063] In this method, the electrode holders 20A and 20B are inserted into the quartz vacuum tube 10 from the openings at both ends of the quartz vacuum tube 10 , and these are packaged in a state where the inside is under a negative pressure.

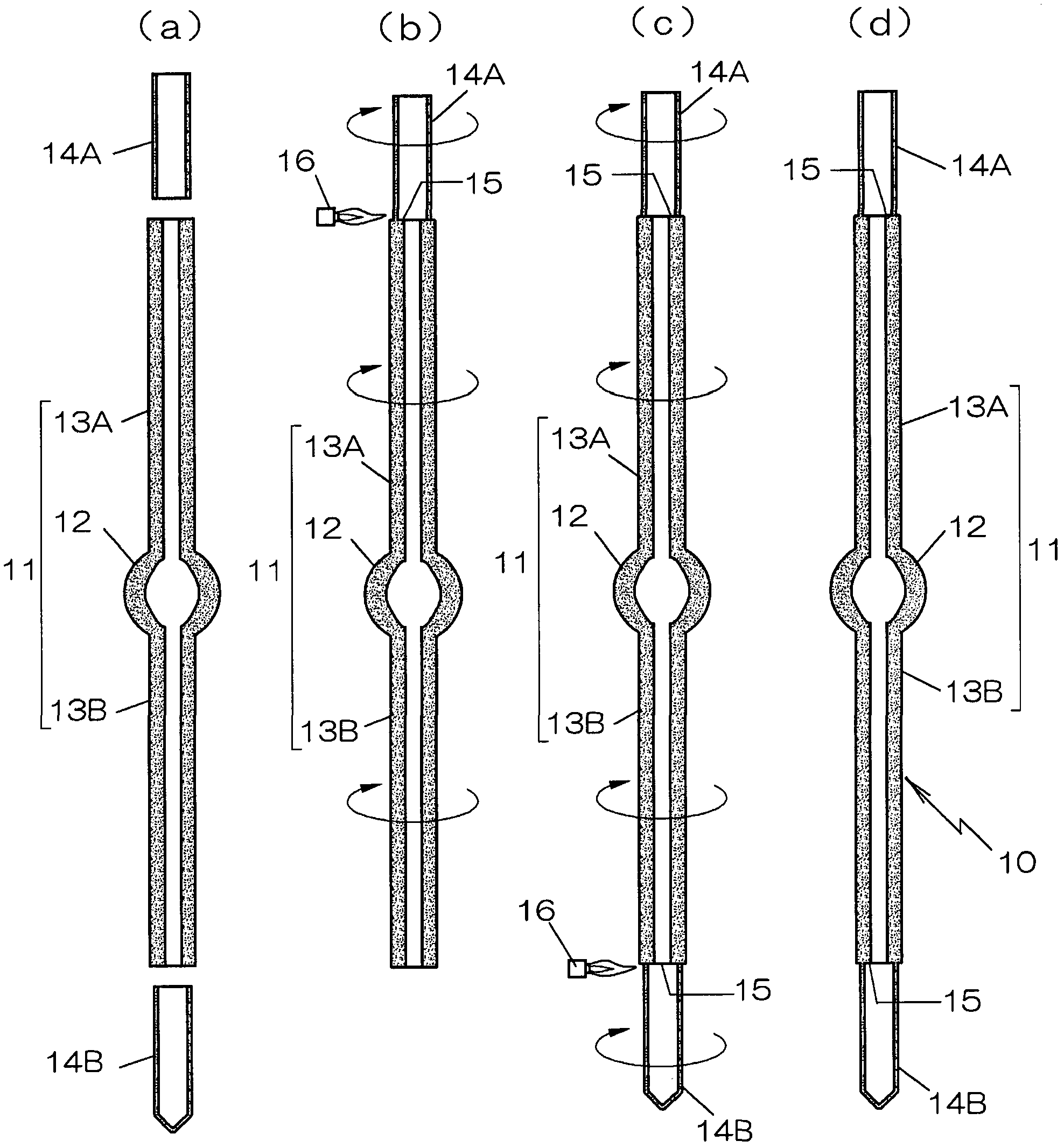

[0064] figure 1 Represents the overall process diagram, including: processing steps from the quartz vacuum tube (refer to figure 2 ) The first electrode holder packaging process ( figure 1 (a)~(b)), the 2nd electrode holder encapsulation process that carries out the 2nd electrode holder 20B encapsulation that is inserted from the other end side of quartz vacuum tube 10 ( figure 1 (c) to (d)), an annealing process for removing deformation generated on the quartz, and a cutting process for cutting both ends of the quartz vacuum tube 10 and processing them into predetermined lengths ( figure 1 (e)), ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com