Standing wave type ultrasonic dust collector and dustcollection method thereof

A technology for vacuum cleaners and ultrasonic transducers, applied in the installation of vacuum cleaners, electrical equipment, cleaning equipment, etc., can solve the problems of compactness, light weight and energy utilization of vacuum cleaners, which are difficult to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

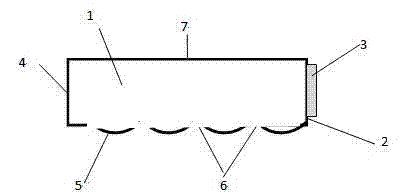

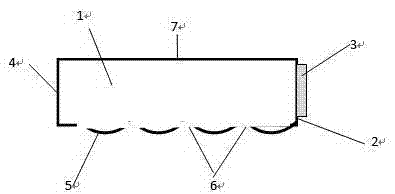

[0015] The structure of embodiment one is as figure 1 shown.

[0016] Each wall of the hexahedral cavity of the ultrasonic cleaner is made of a metal thin copper plate with a thickness of 0.5mm; the sound radiation surface 2 and the sound reflection surface 4 are parallel, and the distance between them d for 9 lambda / 4 (= 38.3 mm), where lambda is the wavelength of ultrasound (=17mm) to form a standing wave ultrasonic field in the cavity (1); the length, width and height of the standing wave sound field are 38.3mm, 20mm and 10mm respectively. The sound radiating surface is driven by a piezoelectric sheet (3) located outside it. The length, width, and thickness of the piezoelectric sheet are 20mm, 10mm, and 2mm, respectively, and are bonded on the outside of the sound radiating surface. The frequency of the driving voltage is 20kHz, and the amplitude is 260Vrms; with the sound pressure node line on the bottom of the ultrasonic cleaner as the center line,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com