Transmission of mandrel thrust trolley of perforating machine

A technology of thrust trolley and transmission device, which is applied to the driving device of metal rolling mill, metal rolling, manufacturing tools, etc., which can solve the problems of potential safety hazards, achieve stable operation, high safety factor, and reduce the effect of motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

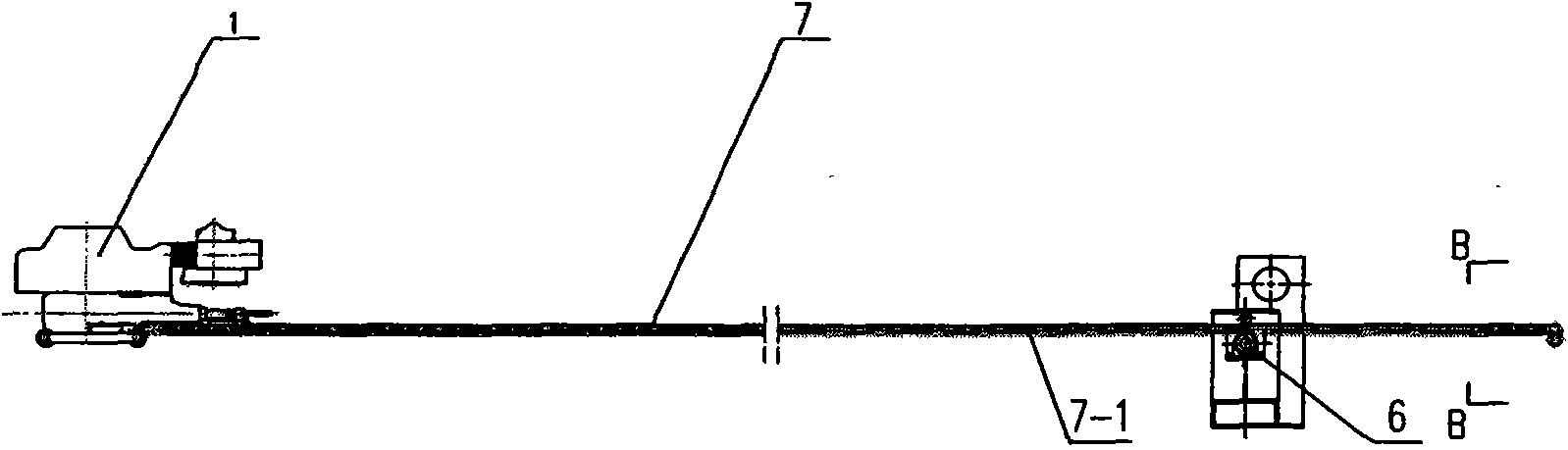

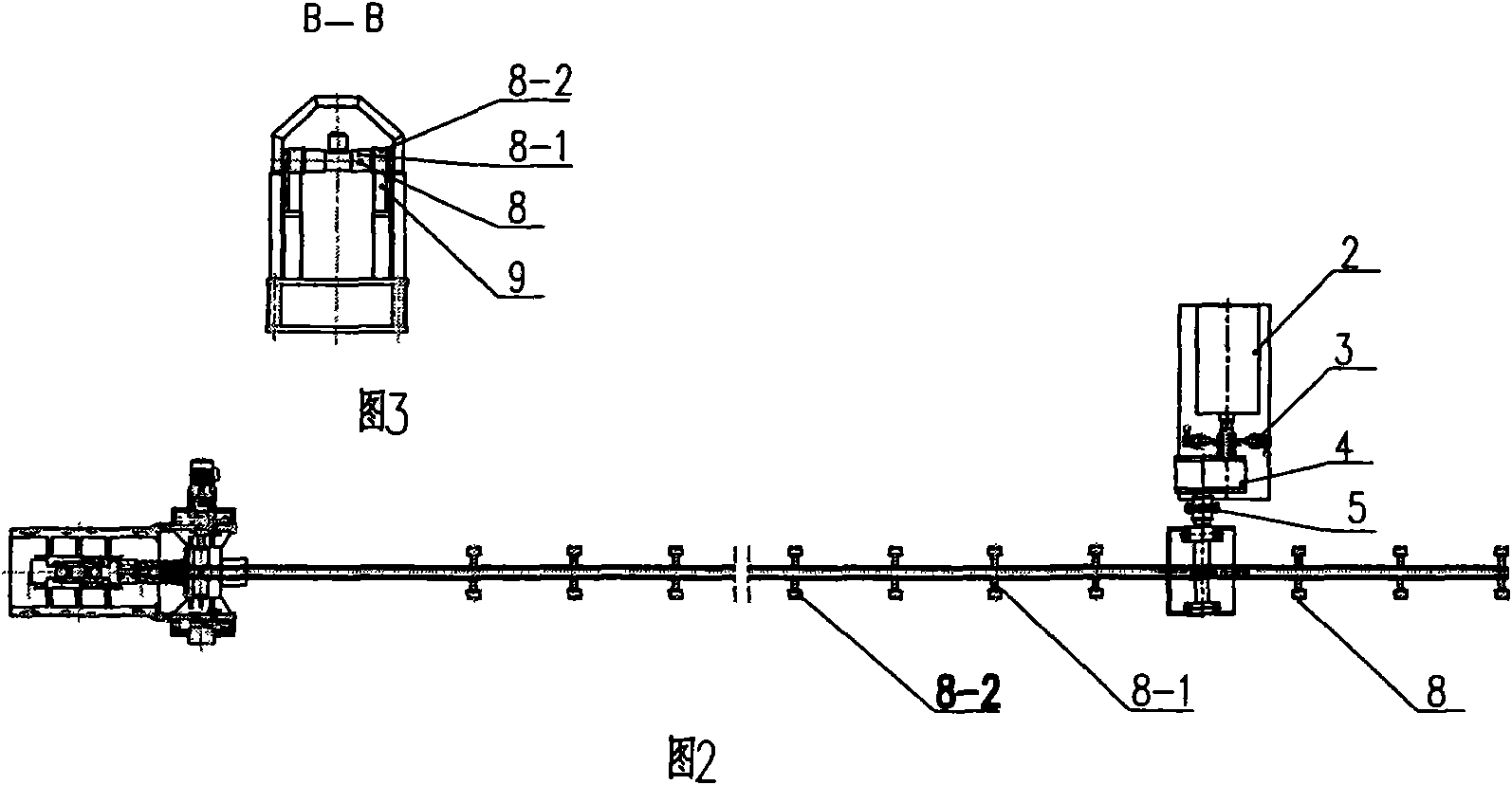

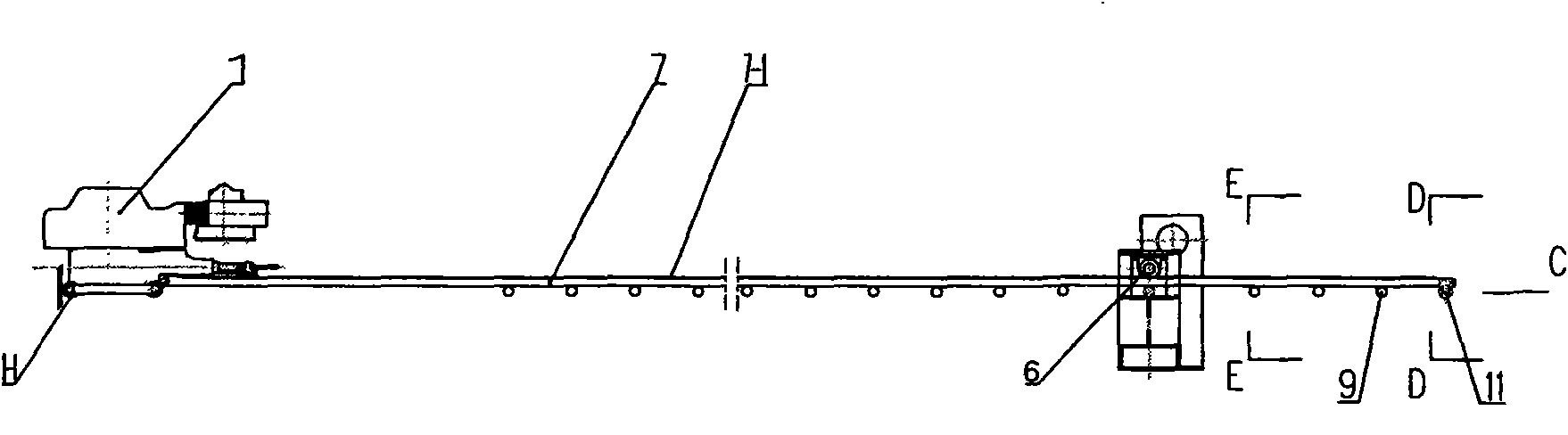

[0018] Such as Figure 4 , 5 , 6, 7, and 8, a transmission device for a thrust trolley of a piercing machine, including: a power system composed of a motor 2, a coupling 3 with a brake disc, a reducer 4, and a coupling 5 , a rack and pinion mechanism formed by meshing a pinion 6 and a long rack 7, the ejector trolley 1 connected with the long rack 7, the output shaft coupling 5 of the reducer 4 and the The pinion 6 is connected, and it is characterized in that: the tooth surface 7-1 of the long rack 7 is set upward, and the lower part of the long rack 7 is equipped with a long slide plate 7-2, and the slide plate 7-2 is placed Above the roller table 9, the long rack 7 can slide on the roller table 9; the roller table 9 is used to support the middle part of the rack, and is composed of a plurality of rollers 9-1, each roller 9-1 is fixed on the track seat 10 through the bearing seat 9-1-3; the tail of the long rack 7 is supported on the two guide rails 10-1 on the track seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com