Manufacturing method for continuously rolling seamless steel pipe by using hollow mandril

A hollow mandrel and seamless steel pipe technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as difficulty in mass production, large rolling mill load, complex heat treatment process, etc., to reduce tool consumption costs, The effect of reducing production costs and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The manufacturing method of the hollow mandrel for producing the continuous rolling seamless steel pipe of the present invention will be described with reference to the examples.

[0030] The manufacturing method of the hollow mandrel of the production continuous rolling seamless steel pipe of the present invention, this method comprises the following steps:

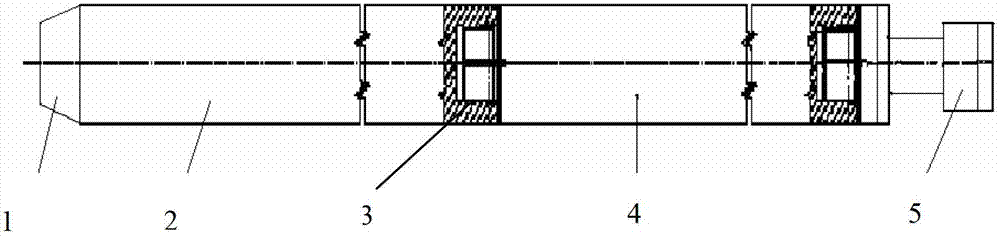

[0031] ① Design of hollow mandrel steel types and specifications

[0032] It is determined that the steel type used for the hollow mandrel is 30Cr3MoV forging billet, and the mandrel used for continuous rolling of seamless steel pipes on the equipment of the ASSEL unit is determined to be Φ250×3850mm, and rolled to Φ176×41×10650mm and 186mm by the ASSEL unit. ×36×10900mm steel pipe is used as the base material for making the hollow mandrel. Finally, the base material of Φ176×41×10650mm is processed into a mandrel of Φ171×35×10500mm, and the base material of 186×36×10900mm is processed into a 176.4×32 ×10500mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com