Full-automatic die-cutting feeding, material-receiving and discharging mechanism for lithium battery pole piece

A lithium battery, fully automatic technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unsmooth feeding, large feeding position error, and inability to ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

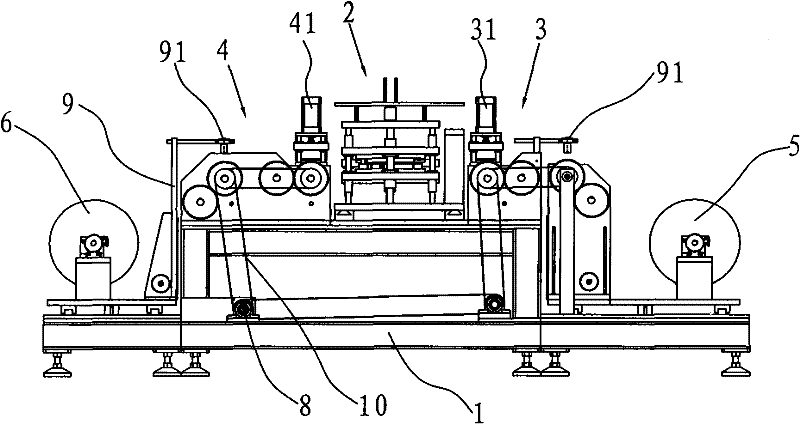

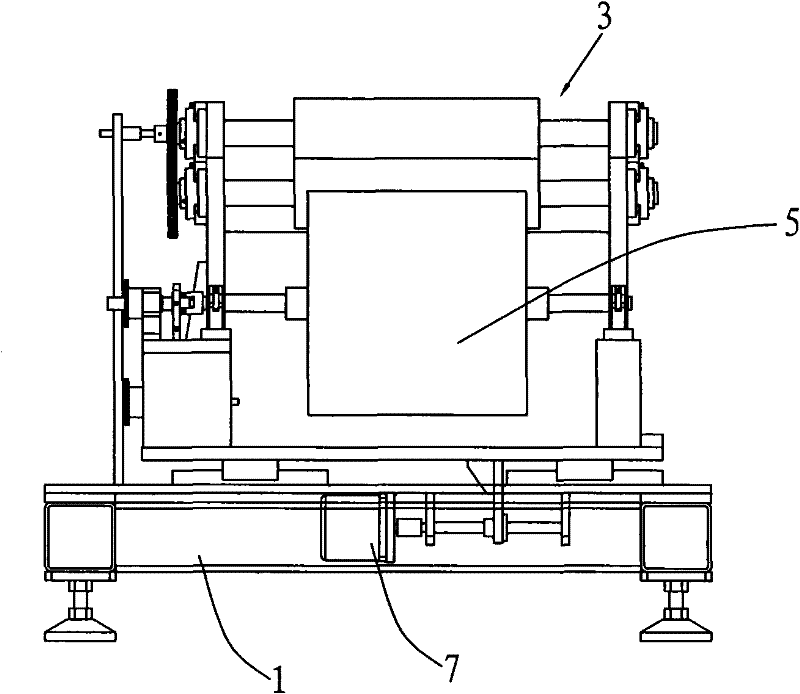

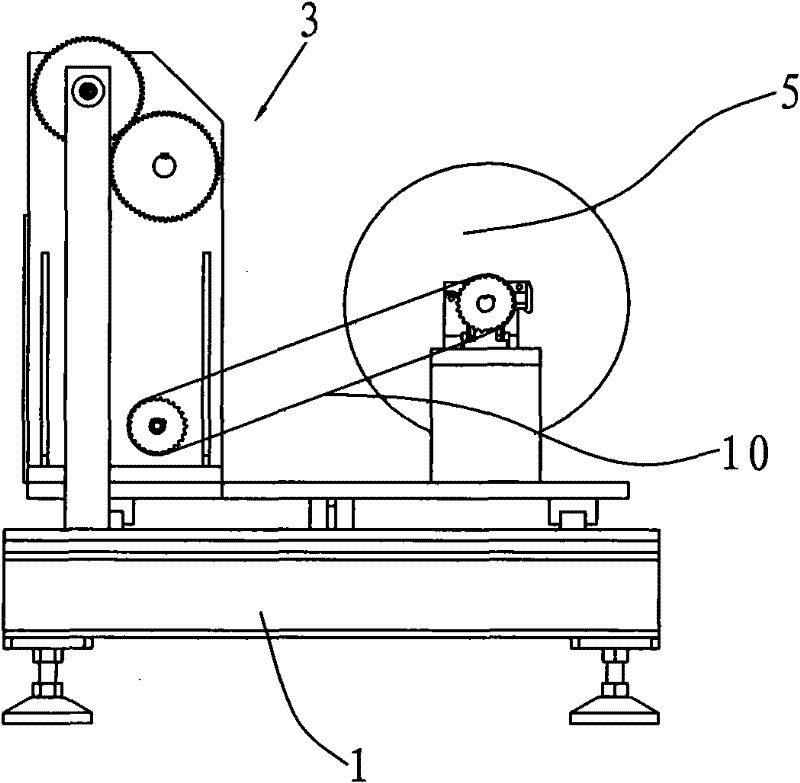

[0018] See Figure 1 to Figure 8 Shown: the present invention adopts following technical scheme, and it comprises that it comprises frame body 1, feeding mechanism 2, material discharging mechanism 3, material receiving mechanism 4, material discharging wheel 5, material receiving wheel 6, on frame body 1 from one end to the other One end is provided with discharging wheel 5, discharging mechanism 3, feeding mechanism 2, receiving mechanism 4, receiving wheel 6 in turn, and discharging wheel 5 and receiving wheel 6 are respectively fixed on the sliding plate and slidingly connected with frame body 1, One side of the receiving wheel 6 is fixedly connected with a support 9, and the support 9 and the feeding mechanism 3 are respectively provided with a detection head 91, and the lower ends of the discharging wheel 5 and the receiving wheel 6 are respectively provided with a deviation correction device 7, and the discharging mechanism 3 , The receiving mechanism 4 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com