Erosion-resistant downhole choke for sour gas well

A technology of anti-erosion and choke nozzle, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problem of low hydrogen sulfide corrosion resistance, inability to meet the application of sulfur-containing gas fields, and affect gas production, etc. problem, to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

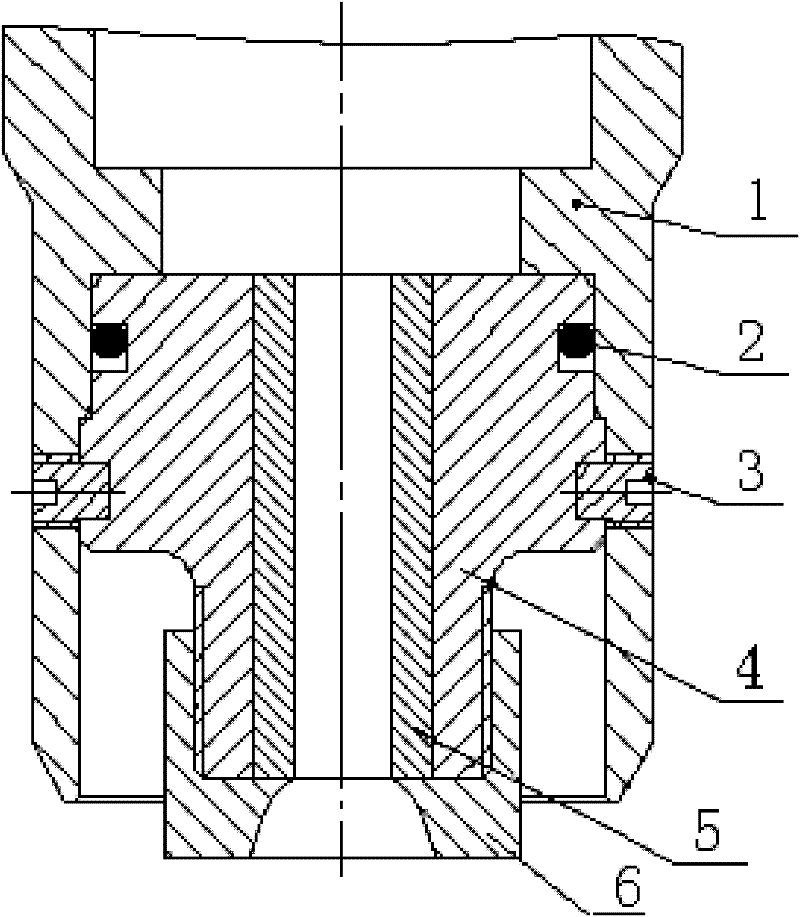

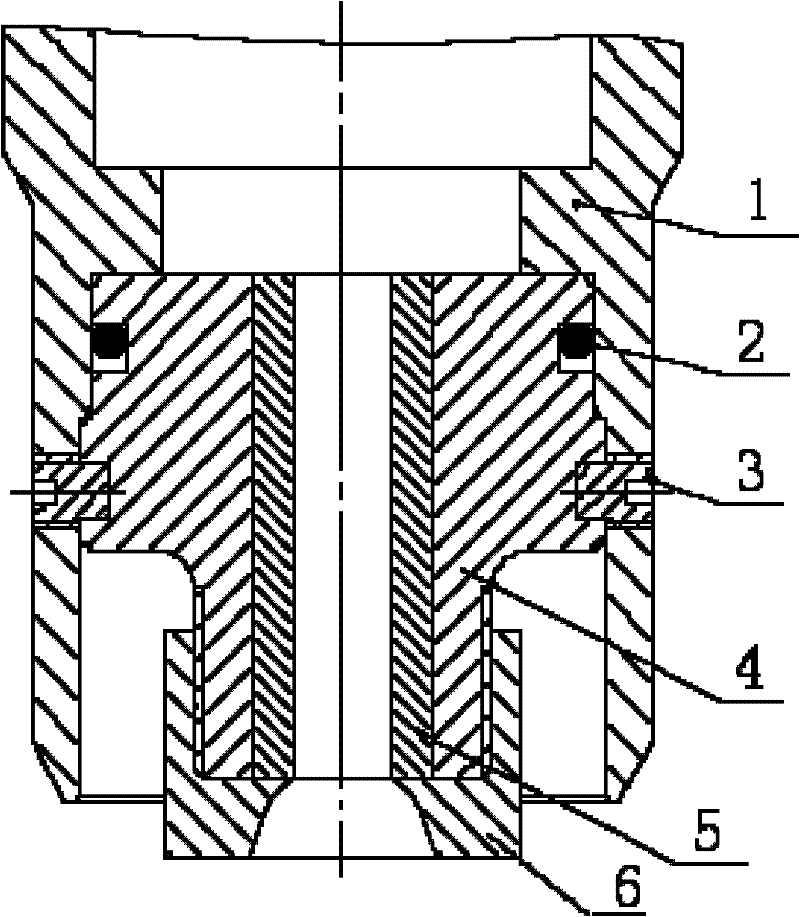

[0012] Embodiment 1: Taking an anti-erosion downhole choke nozzle used in a sour gas well as an example, it will be described in detail.

[0013] refer to figure 1 , The erosion-resistant downhole choke nozzle for sulfur-containing gas wells of the present invention includes: a nozzle sleeve 1 , a sealing ring 2 , a pin 3 , a nozzle body 4 and a bushing 5 .

[0014] Due to the different structures of downhole throttling nozzles, there are many names given to the nozzle cover 1 by technicians, and the function of the nozzle cover 1 is to fix the nozzle. The mouth cover 1 of the present invention is cylindrical, and the upper end of the mouth cover 1 is threaded. There is a center hole in the mouth cover 1, and an inwardly protruding annular step is arranged in the center hole of the mouth cover 1, and a nozzle body 4 is fixed at the lower end of the annular step in the center hole of the mouth cover 1.

[0015] The nozzle body 4 is in the shape of a cylinder, and the diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com