Nano silicon thin film transistor pressure sensor

A nano-silicon film and pressure sensor technology, applied in the field of sensors, can solve the problems of pressure sensor zero drift and other problems, and achieve the effects of zero drift compensation, high sensitivity, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

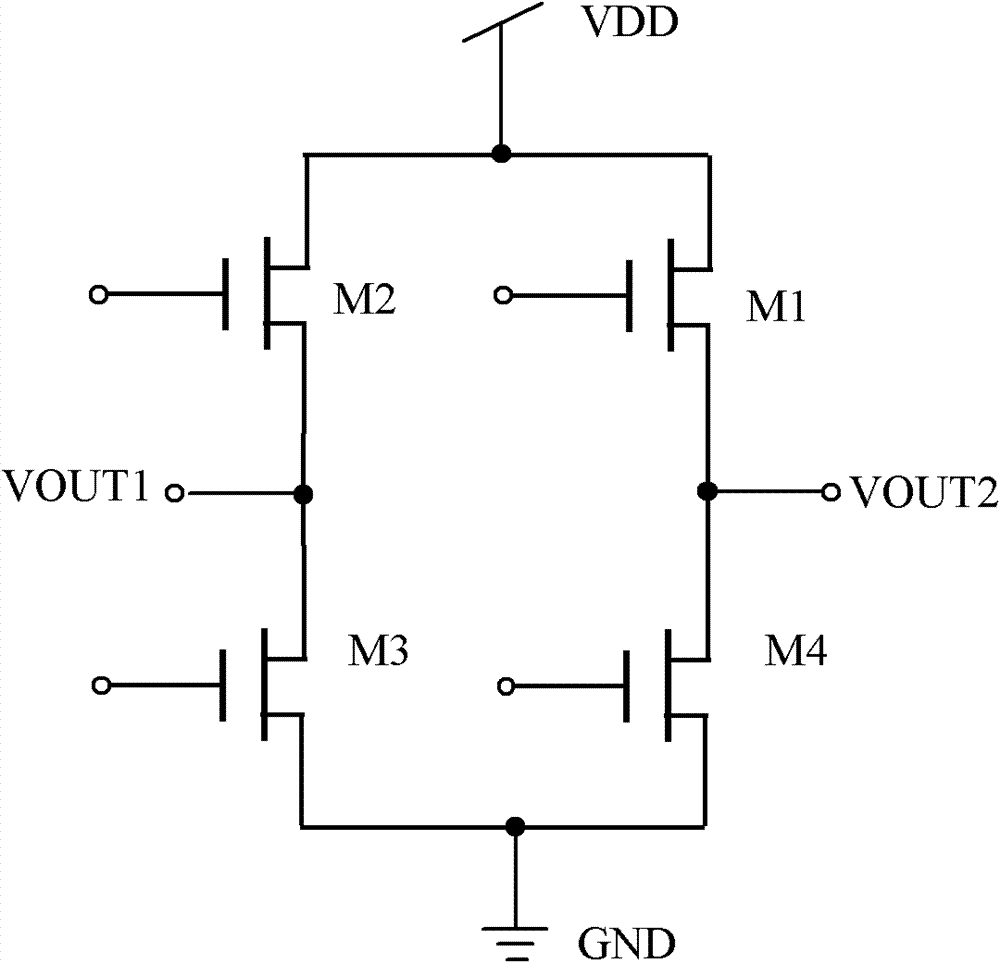

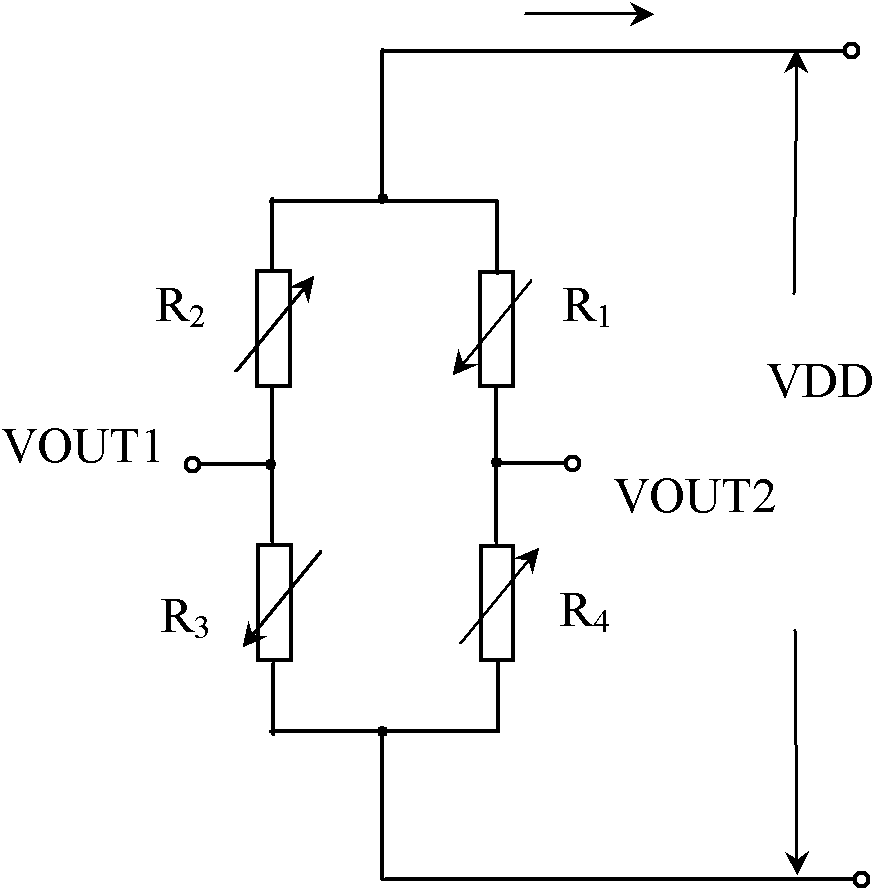

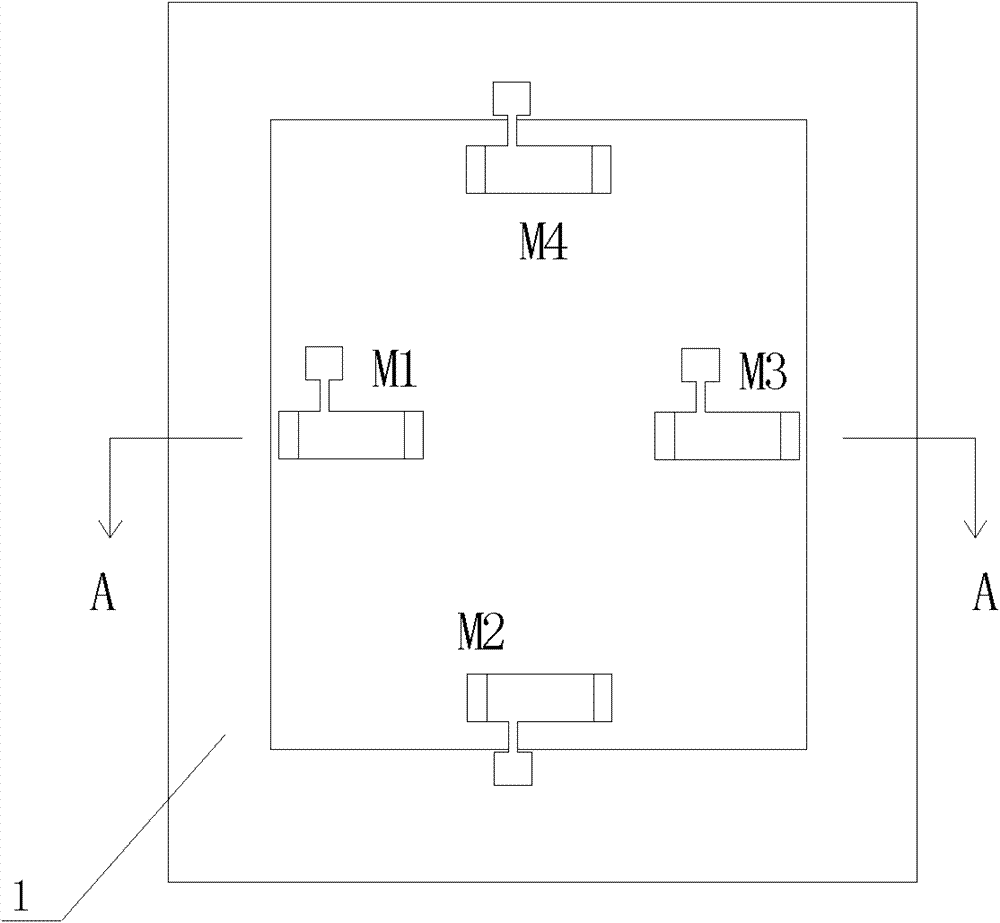

[0016] Specific implementation mode one: the following combination Figure 1 to Figure 6 This embodiment mode is described. This embodiment mode is composed of a first nano-silicon thin film transistor M1, a second nano-silicon thin film transistor M2, a third nano-silicon thin film transistor M3, a fourth nano-silicon thin film transistor M4 and a single crystal silicon substrate 1.

[0017] The source of the first nanometer silicon thin film transistor M1 is connected to the drain of the fourth nanometer silicon thin film transistor M4, the drain of the first nanometer silicon thin film transistor M1 is connected to the drain of the second nanometer silicon thin film transistor M2, and the second nanometer silicon thin film transistor The source of M2 is connected to the drain of the third nanometer silicon thin film transistor M3, and the source of the third nanometer silicon thin film transistor M3 is connected to the source of the fourth nanometer silicon thin film transis...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is a further description of Embodiment 1. The single crystal silicon substrate 1 is a p-type double-sided polished single crystal silicon wafer in the crystal orientation. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is a further description of Embodiment 2, and the thickness of the single crystal silicon substrate 1 is 400 microns. Others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com