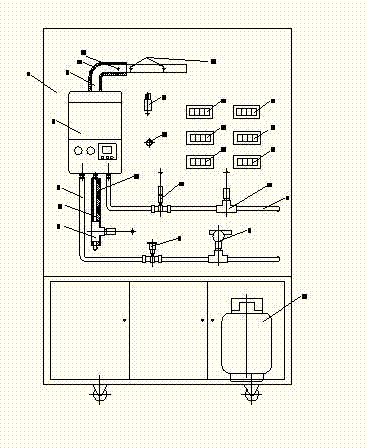

Testing stand for thermal balancing test of boiler

A heat balance and boiler technology, applied in the field of teaching instruments, can solve the problems that the power plant does not necessarily provide experimental conditions and opportunities, the operation requirements are high, and there is no sales of boiler heat balance test benches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Concrete structure of the present invention is:

[0019] a. A gas boiler 3 is installed on the test bench 2. The lower end of the gas boiler 3 is equipped with an inlet pipe 4, an outlet pipe 5 and a water inlet pipe 9. The upper end of the gas boiler 3 is equipped with a smoke exhaust pipe 1.

[0020] b. Inlet water temperature gauge 12, gas flow gauge 13, gas pressure gauge 14, outlet water temperature gauge 15, water flow gauge 16 and flue gas differential pressure gauge 17 are installed on the test bench 2.

[0021] c. The smoke exhaust pipe 1 has a differential pressure measuring point 20 and a flue gas composition and temperature measuring point 21. The flue gas differential pressure sensor 19 installed on the test bench 2 communicates with the differential pressure measuring point 20 through the pipeline, and the flue gas The differential pressure sensor 19 is connected to the flue gas differential pressure gauge 17;

[0022] d. An intake vortex flowmeter 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com