Semiconductor luminous device

A light-emitting device, semiconductor technology, applied in the direction of semiconductor devices, electric solid state devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

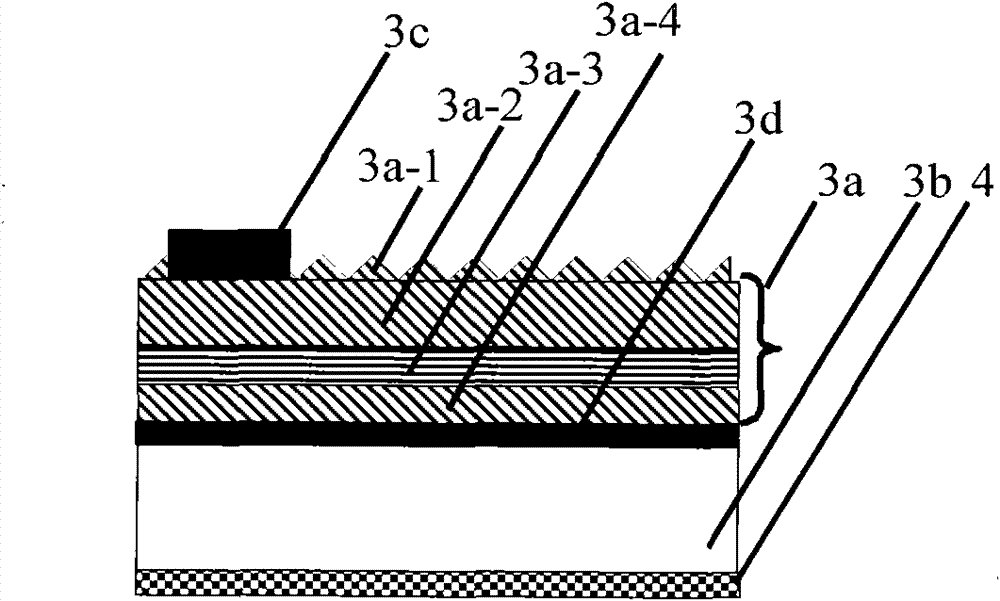

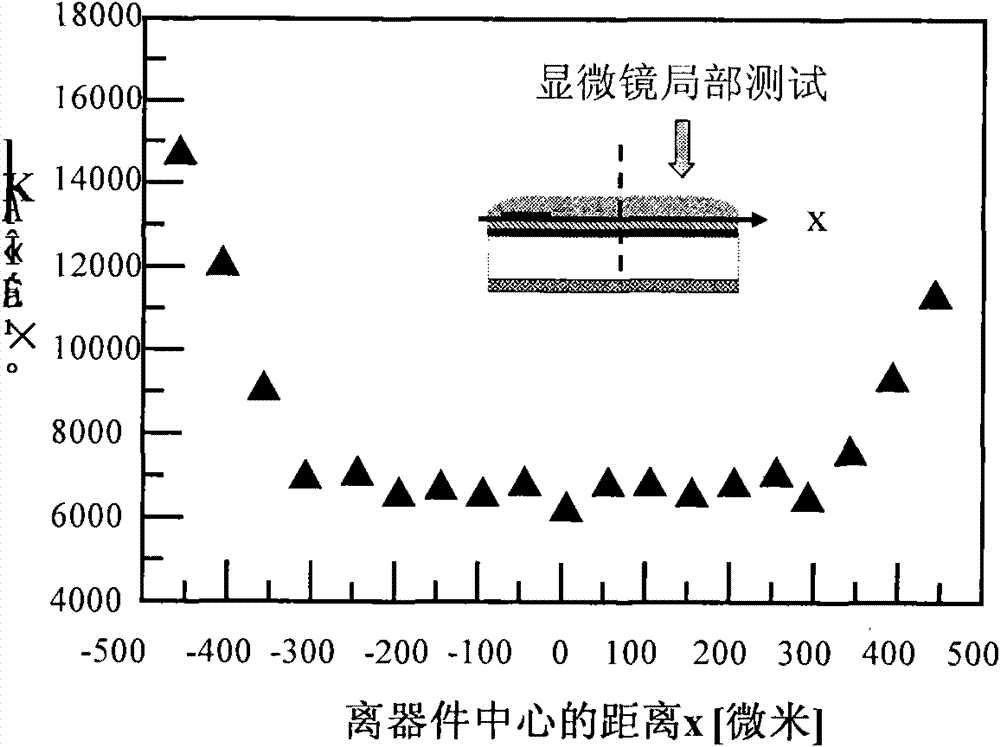

[0112] Embodiment 1——Packaging of a glass sheet with a smooth surface placed on a fluorescent glue

[0113] Prepare 2 AlN packaging substrates with electrode structures and 2 smooth transparent glass sheets (size 1mm2, the same as thinfilm chips, such as Figure 2a ), ultrasonic cleaning in ethanol solution for 3 minutes for surface cleaning. Store the treated glass flakes in a clean place for subsequent use. Paste the thinfilm chip (1mm2,) on the AlN packaging substrate with Au0.8Sn0.2 alloy glue. Place the packaging substrate together with the chip on a heating plate with a set temperature of 340° C. for 30 seconds and then take it off. The alloy glue is melted at high temperature and then cooled and solidified, so that the chip is bonded and fixed on the AlN substrate. The chip and the AlN substrate were soaked in an acetone organic solution and ultrasonically cleaned for 3 minutes to remove the waxy adhesive on the alloy surface. Electrode welding is performed with a g...

Embodiment 2

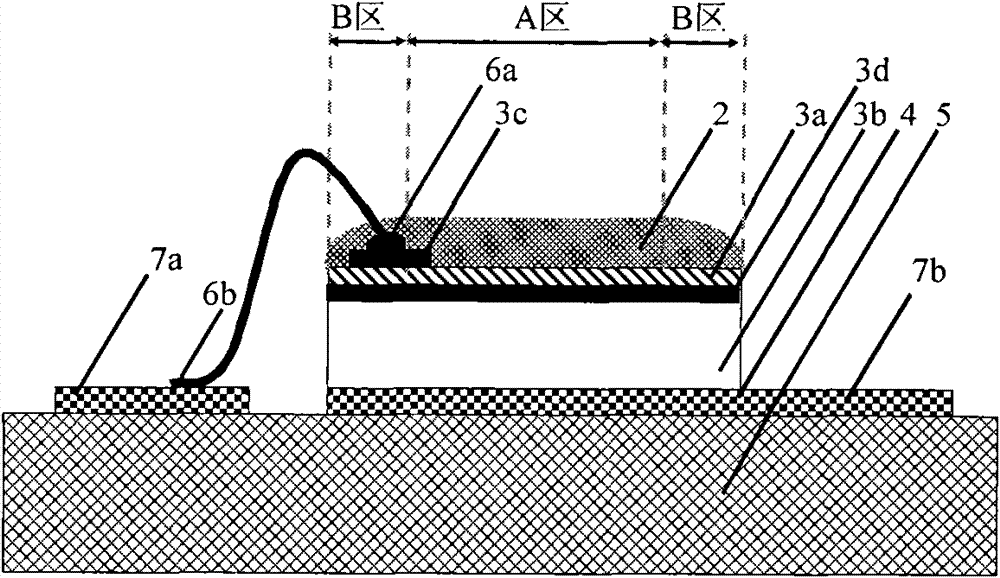

[0115] Example 2 - Glass flake with tiny protrusions on one side

[0116] Prepare two AlN packaging substrates with electrode structures and two transparent glass flakes with tiny protrusions on one side (size 1mm2, the same as thinfilm chips), and ultrasonically clean them in ethanol solution for 3 minutes for surface cleaning. After treatment, the tiny convex surface on the side of the transparent glass sheet presents a smooth curved shape, and the height of the convex is about 400 μm, which is greater than the height of the arc of the gold wire, such as Figure 3a . Store the treated glass flakes in a clean place for subsequent use. Paste the thinfilm chip (1mm2,) on the AlN packaging substrate with Au0.8Sn0.2 alloy glue. Place the packaging substrate together with the chip on a heating plate with a set temperature of 340° C. for 30 seconds and then take it off. The alloy glue is melted at high temperature and then cooled and solidified, so that the chip is bonded and fi...

Embodiment 3

[0120] Example 3 - Combination of transparent beads mixed with fluorescent glue and smooth glass sheet

[0121] Prepare 2 AlN packaging substrates with electrode structures and 2 transparent glass flakes with a smooth surface (size 1mm2, the same as the thinfilm chip), and ultrasonically clean them in ethanol solution for 3 minutes to clean the surface. Store the treated glass flakes in a clean place for subsequent use. Paste the thinfilm chip (1mm2,) on the AlN packaging substrate with Au0.8Sn0.2 alloy glue. Place the packaging substrate together with the chip on a heating plate with a set temperature of 340° C. for 30 seconds and then take it off. The alloy glue is melted at high temperature and then cooled and solidified, so that the chip is bonded and fixed on the AlN substrate. The chip and the AlN substrate were soaked in an acetone organic solution and ultrasonically cleaned for 3 minutes to remove the waxy adhesive on the alloy surface. Electrode welding is performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com