Packaging structure and method of high-power LED

A LED packaging and high-power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inconsistent color temperature of light source space, lower product reliability, inconsistent thickness, etc., to achieve uniformity, improve reliability, improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

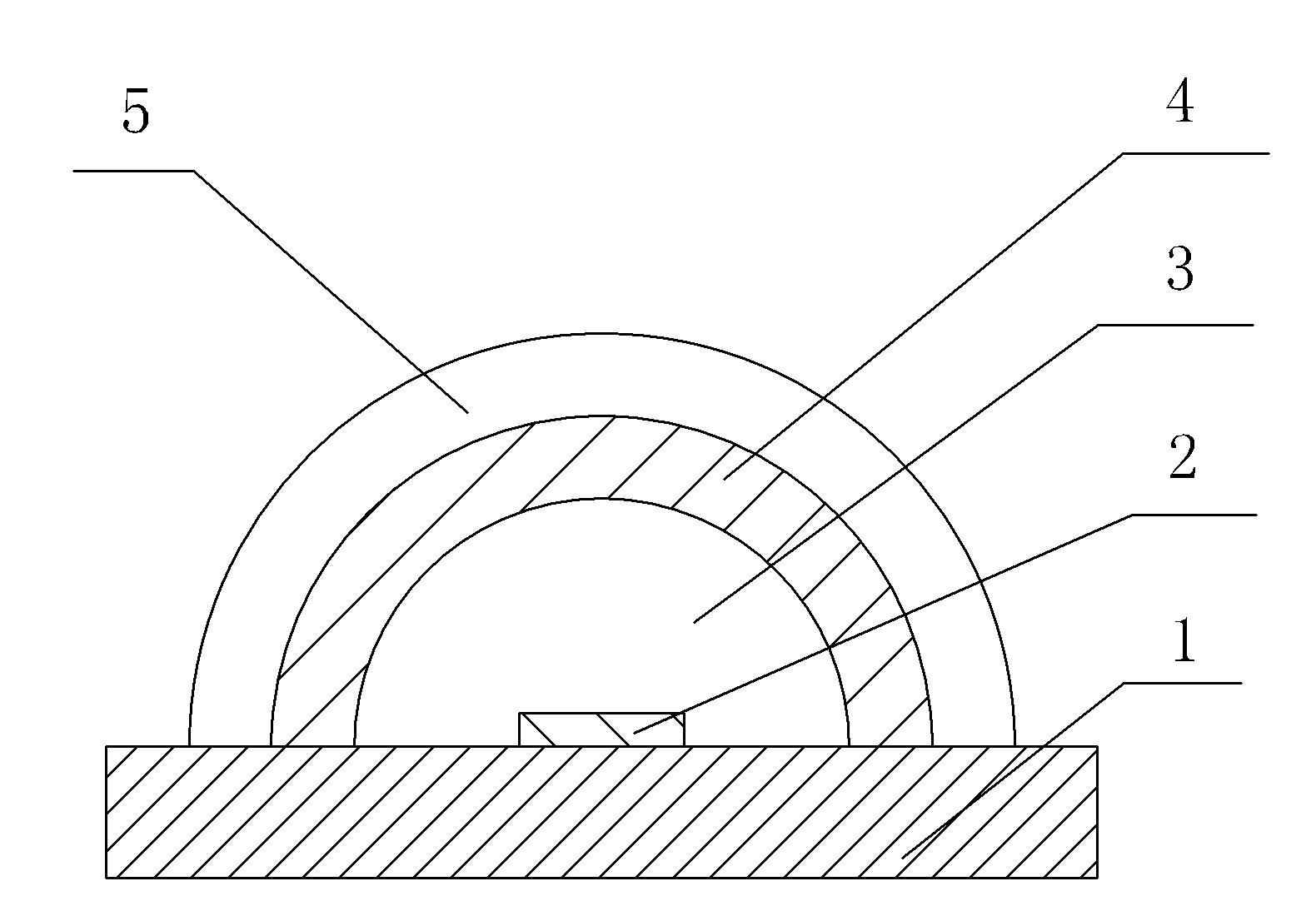

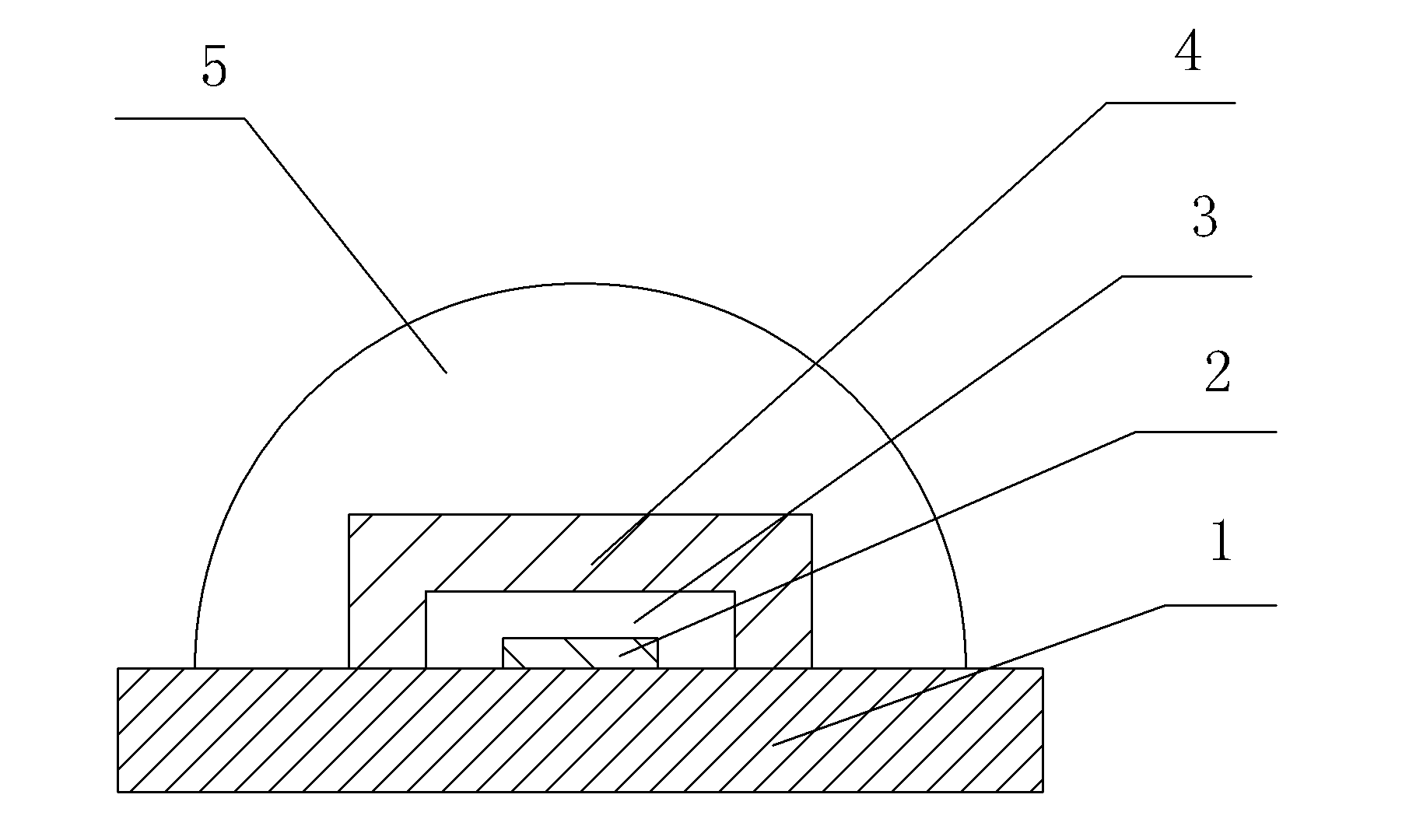

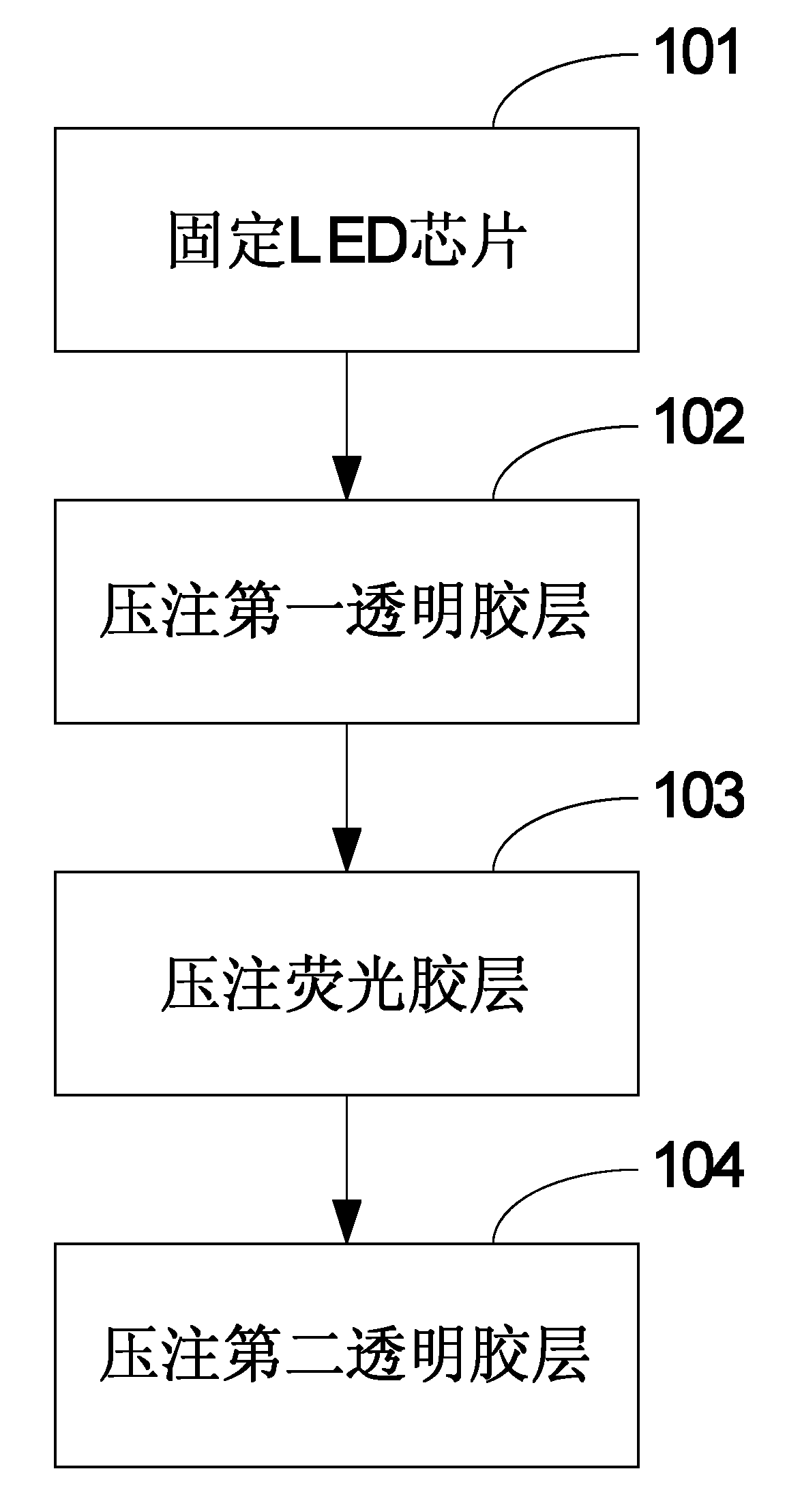

[0010] figure 1 and figure 2 It is a schematic diagram of two embodiments of the high-power LED packaging structure of the present invention. The high-power LED packaging structure provided by the embodiment of the present invention includes: a substrate 1 , an LED chip 2 , a first transparent adhesive layer 3 , a fluorescent adhesive layer 4 and a second transparent adhesive layer 5 .

[0011] Among them, the LED chip 2 is fixed on one side of the substrate 1; the first transparent adhesive layer 3 is a layer of transparent adhesive formed by pressing the LED chip 2 as the center. In this embodiment, the first transparent adhesive layer 3 is pressed by silica gel Injection molding, the refractive index of the first transparent adhesive layer 3 is greater than 1.41, and the hardness is greater than shore A 50; the fluorescent adhesive la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com