Vacuum processing apparatus and vacuum transfer apparatus

一种真空处理装置、运送装置的技术,应用在输送机物件、运输和包装、炉等方向,能够解决生产率下降、运送效率或生产率下降、运送机器人应对困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

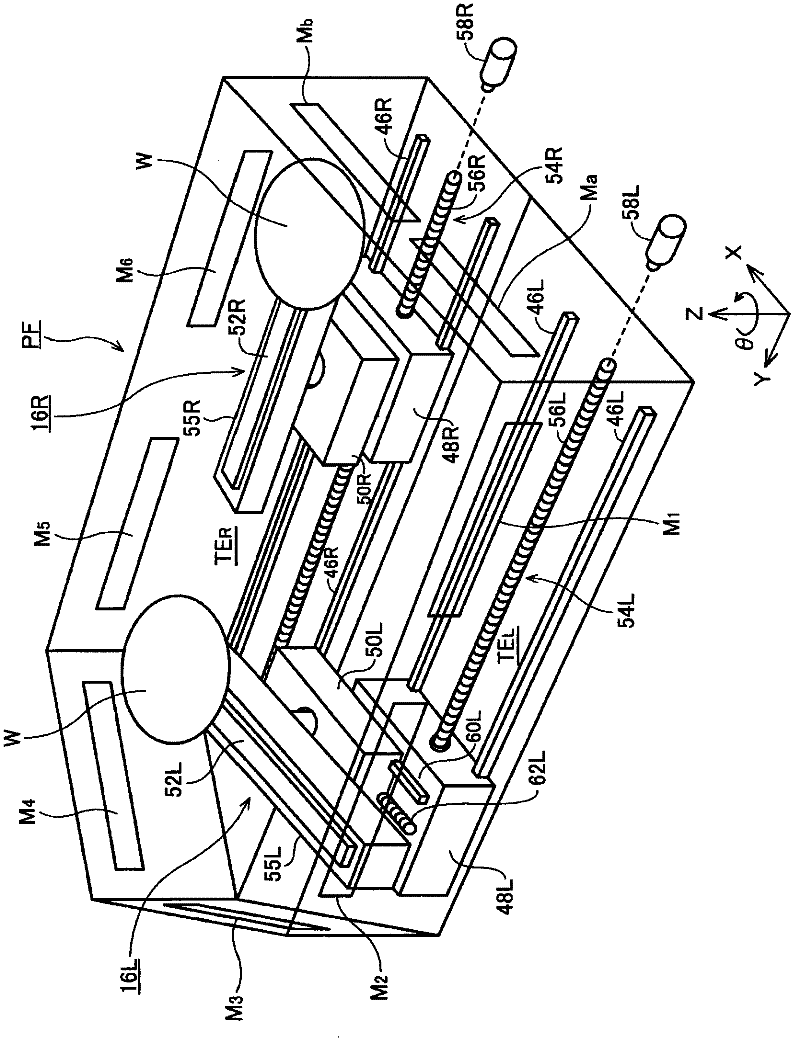

[0066] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

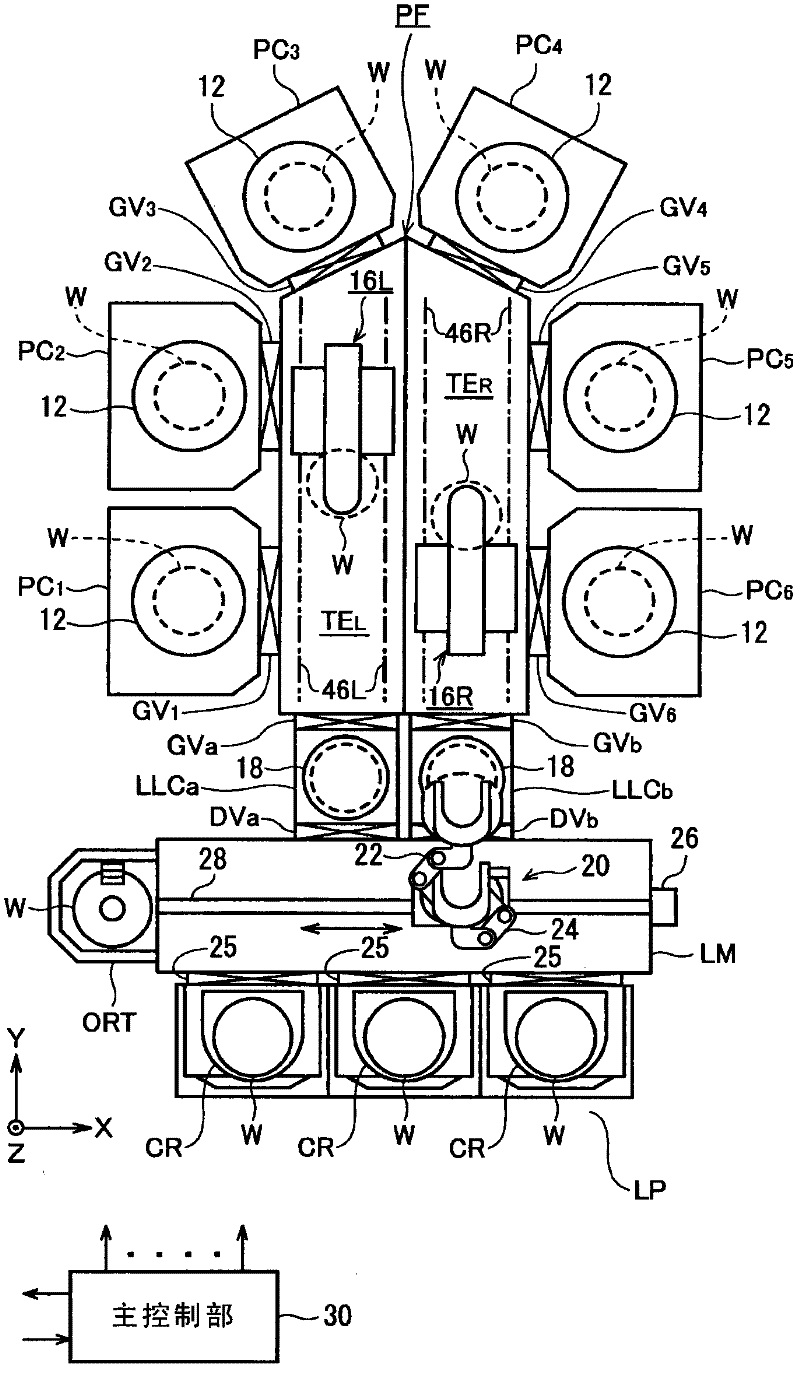

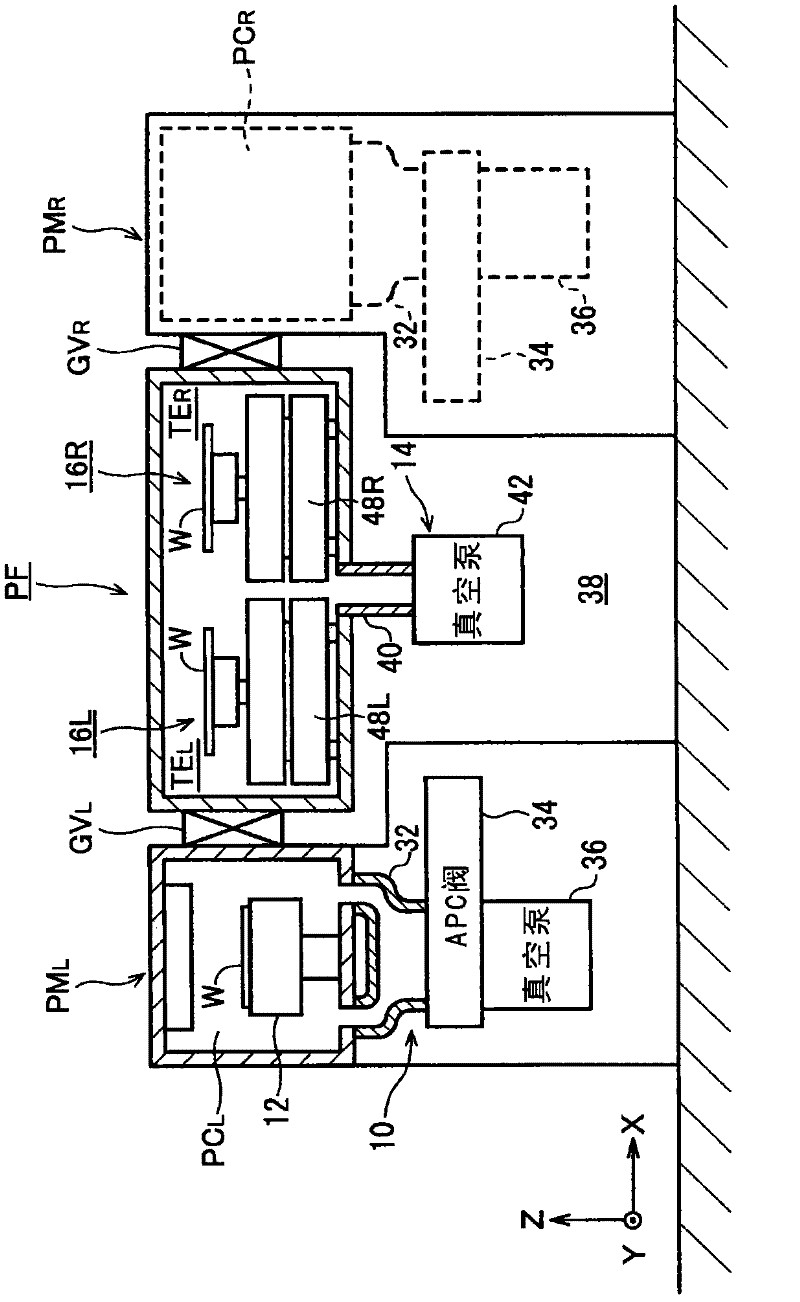

[0067] figure 1 The overall structure of the vacuum processing apparatus of the cluster type frame type according to an embodiment of the present invention is shown. The vacuum processing device is installed in the clean room, and 6 vacuum processing chambers (vacuum processing chambers) PC are arranged in a cluster so as to be adjacent to the periphery of the vacuum platform (vacuum transfer chamber) PF. 1 , PC 2 , PC 3 , PC 4 , PC 5 , PC 6 And 2 loading fixed chambers (loading fixed chamber) LLC a , LLC b The platform has a pentagonal shape in which a pair of sides extending in the depth direction of the device (the Y direction in the figure) is approximately twice longer than the other sides.

[0068] In more detail, the gate valve GV is passed through the gate valve GV on the long side of the left side on the platform PF in the order of clockwise rotation in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com