Computer-aided design (CAD) and computer-aided manufacturing (CAM) personalized substrate sandwich ceramic bracket and manufacturing method thereof

A sandwich and bracket technology, applied in the application field of biomedical materials, can solve problems such as poor tooth surface adhesion and poor bonding performance, and achieve the effects of increasing mechanical bonding strength, improving mechanical bonding deficiency, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

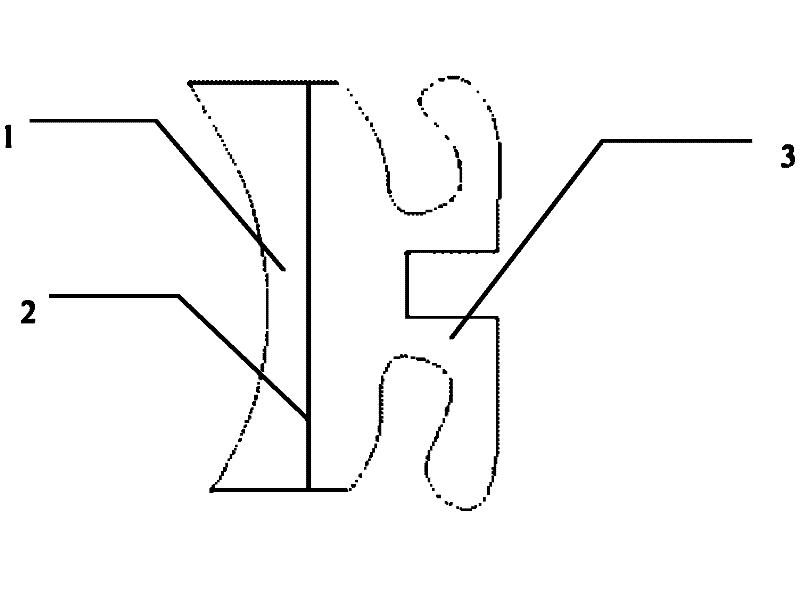

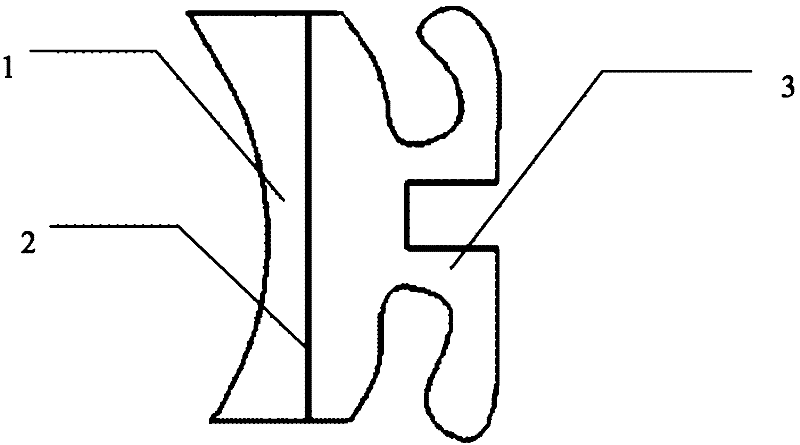

[0019] Such as figure 1 The CAD and CAM personalized base sandwich ceramic brackets shown in this embodiment are composed of personalized bracket bases that match the finished ceramic brackets and are fully fitted with the lip surface of the teeth and the bottom surface of the finished ceramic brackets. The thickness of the substrate is 0.4-0.6cm (depending on the material), and the ceramic adhesive 2 bonds the personalized bracket base 1 and the finished ceramic bracket 3 into one body. The thickness of agent 2 is controlled at 30-50 μm.

[0020] The production method is as follows:

[0021] Use the chairside 3D scanner to obtain the shape information of the labial surface of the tooth, with an accuracy of 0.02mm; apply CAD and CAM software to design a personalized labial bracket base according to the shape of the tooth surface, the size of the base matches the finished bracket, and the lip of the tooth The surface and the bottom surface of the bracket are completely fitted...

Embodiment 2

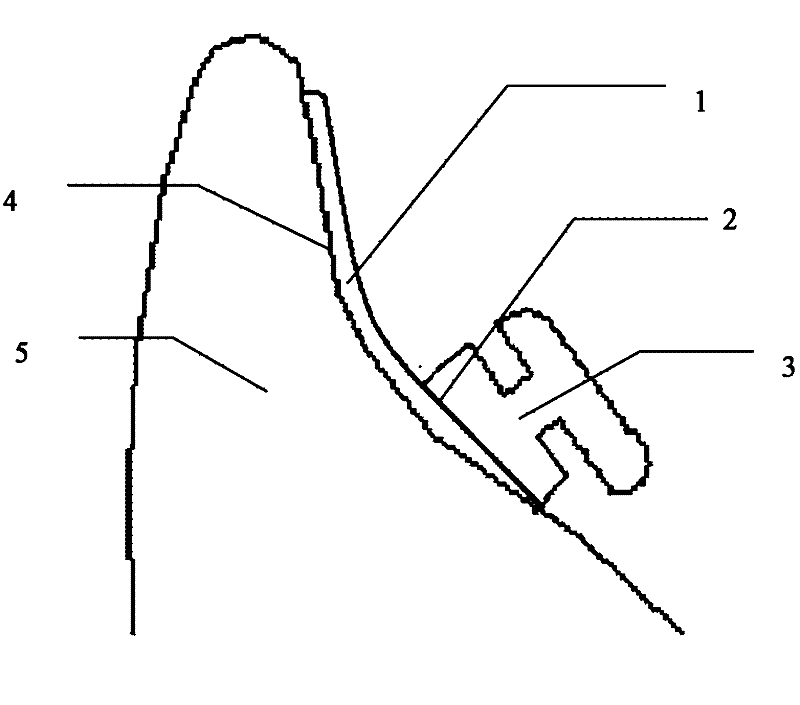

[0023] Such as figure 2 The CAD and CAM personalized base sandwich ceramic brackets shown in this embodiment are composed of personalized bracket bases that match the finished ceramic brackets and are fully fitted with the lingual surface of the teeth and the bottom surface of the finished ceramic brackets. The thickness of the substrate is 0.4-0.6cm (depending on the material), and the ceramic adhesive 2 bonds the personalized bracket base 1 and the finished ceramic bracket 3 into one body. The thickness of agent 2 is controlled at 30-50 μm.

[0024] The production method is as follows:

[0025] Use the scanner to obtain the shape information of the lingual surface of the teeth, and use CAD and CAM software to design the base of the lingual bracket. The base of the lingual bracket wraps around the middle and lower 2 / 3 of the lingual surface, increasing the contact area between the base and the tooth surface, increasing the The bonding strength between the base and the toot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com