Harmless processing technology for waste dangerous chemical containing mercury

A technology for the harmless treatment of hazardous chemicals, applied in the direction of protection devices against harmful chemicals, etc., can solve the problem of lack of harmless disposal of mercury-containing hazardous chemicals, the lack of disposal qualifications and actual disposal capabilities, destruction units, safety Hidden dangers and other problems, to achieve the effect of eliminating hidden dangers of social safety, strong practicability, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 pilot test process:

[0035] (1) Processing object

[0036] Suzhou Shangmei International Cosmetics Co., Ltd. contains highly toxic mercury, 49.5g of mercury iodide, 488.9g of mercury chloride, 223.3g of mercury sulfate, and 1988.1g of mercury acetate.

[0037] (2) Treatment process

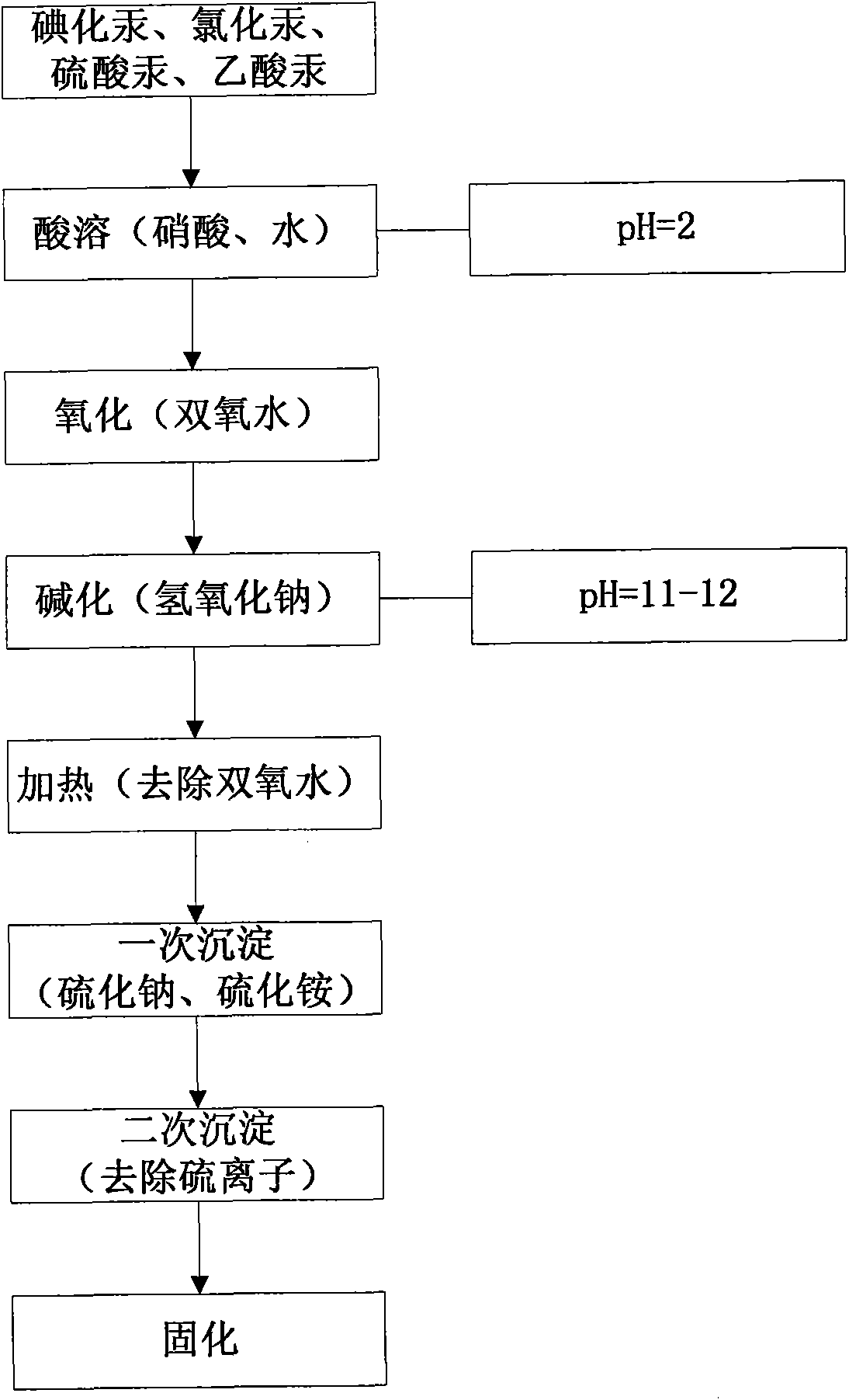

[0038] Process flow diagram as figure 1 Shown:

[0039] In a mobile reactor, add the above-mentioned mercury-containing highly toxic mixture to 3000g of water, and add nitric acid to help dissolve it, so that the pH value of the solution is less than 2; then add hydrogen peroxide (the mass percentage concentration of hydrogen peroxide is 20%-30%) to carry out Oxidation reaction in which the H in hydrogen peroxide is controlled 2 o 2 The molar ratio of mercury to mercury in waste containing mercury is 2.5:1. After the reaction was carried out for 1 hour, all the organic mercury and monovalent mercury in the reaction system were converted into Hg 2+ .

[0040] Then add s...

Embodiment 2

[0047] Embodiment 2 engineering application:

[0048] (1) Processing object

[0049] Wujiang Lvyi Solid Waste Recycling and Disposal Co., Ltd. contains hazardous chemicals containing mercury, 218kg, with a mercury content (average) of 47.18%, and leached mercury of 2378mg / L.

[0050] (2) Process parameters of each processing unit

[0051] Reaction pool: The reaction pool is PP structure, the size is ¢3.0m×2.2m, and the effective volume is 14m 3 , equipped with a stirring device with a power of 7.5kW, an exhaust system on the top (the power of the induced draft fan is 5.5kW), and a set of plate and frame filter press (80m 2 ).

[0052] Curing machine: twin-shaft forced mixer, productivity 25m 3 / h.

[0053] Process flow diagram as figure 1 Shown:

[0054] 100kg of the above-mentioned mercury-containing highly toxic mixture is added to 100kg of water, and nitric acid is added to aid dissolution, so that the pH value of the solution is less than 2; then hydrogen peroxide (...

Embodiment 3

[0061] Embodiment 3 pilot test process:

[0062] (1) Processing object

[0063] Suzhou Shangmei International Cosmetics Co., Ltd. contains highly toxic mercury, 49.5g of mercury iodide, 488.9g of mercury chloride, 223.3g of mercury sulfate, and 1988.1g of mercury acetate.

[0064] (2) Treatment process

[0065] Process flow diagram as figure 1 Shown:

[0066] In a mobile reactor, add the above-mentioned mercury-containing highly toxic mixture to 3000g of water, and add nitric acid to help dissolve it, so that the pH value of the solution is less than 2; then add hydrogen peroxide (the mass percentage concentration of hydrogen peroxide is 20%-30%) to carry out Oxidation reaction in which the H in hydrogen peroxide is controlled 2 o 2 The molar ratio of mercury to mercury in waste containing mercury is 2.5:1. After the reaction was carried out for 1 hour, all the organic mercury and monovalent mercury in the reaction system were converted into Hg 2+ .

[0067] Then add s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com