Municipal domestic waste bag-breaking crushing equipment

A technology for municipal solid waste and crushing equipment, which is applied in the field of municipal solid waste bag breaking equipment, can solve the problems of the quality of waste organic matter fertilizer making, cannot solve the problems of thin shaft winding, and is difficult to run continuously and stably, and achieve stable working performance and reduce Cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

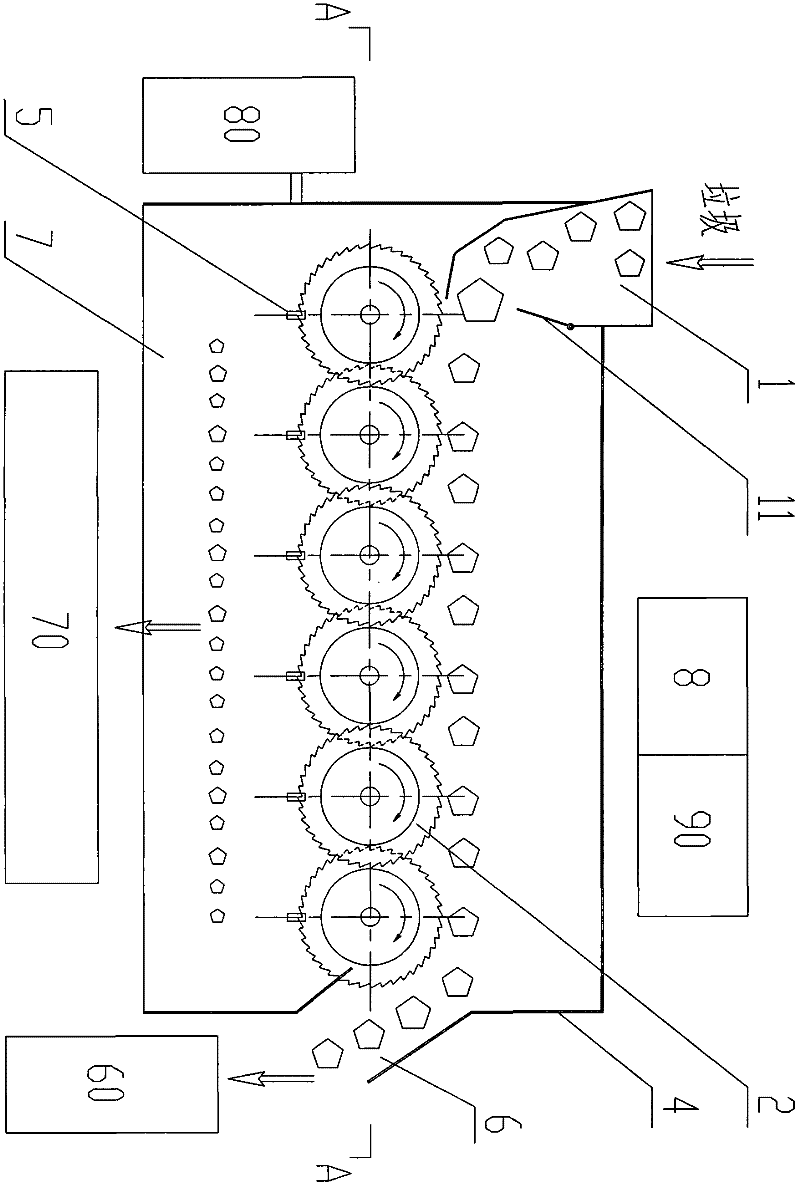

[0023] see figure 1 , the bag-breaking and crushing equipment for municipal domestic waste of the present invention has a set of feeding device 1, bag-breaking and crushing device 2, driving device 3, cabinet frame 4, material cleaning device 5, large block material outlet 6, small block material outlet 7 and Electrical protection device 8 and so on.

[0024] Feeding device 1 is made of loading hopper and bulky object limiter 11 etc. The setting of the bulky item limiter 11 of the feeding device 1 is to prevent the bulky items in the garbage from entering the bag breaking equipment. The height of the bulky item limiter 11 is determined by the nature of the garbage and the height of the bulky material outlet 6 .

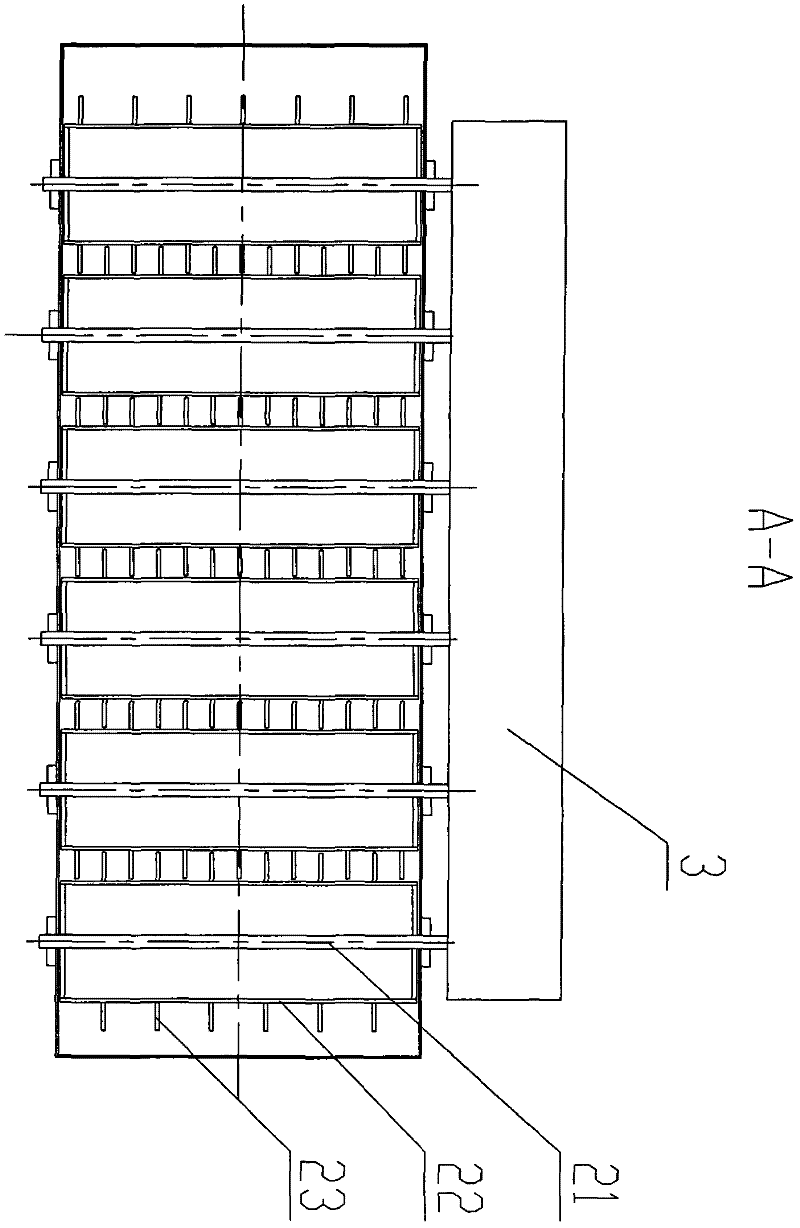

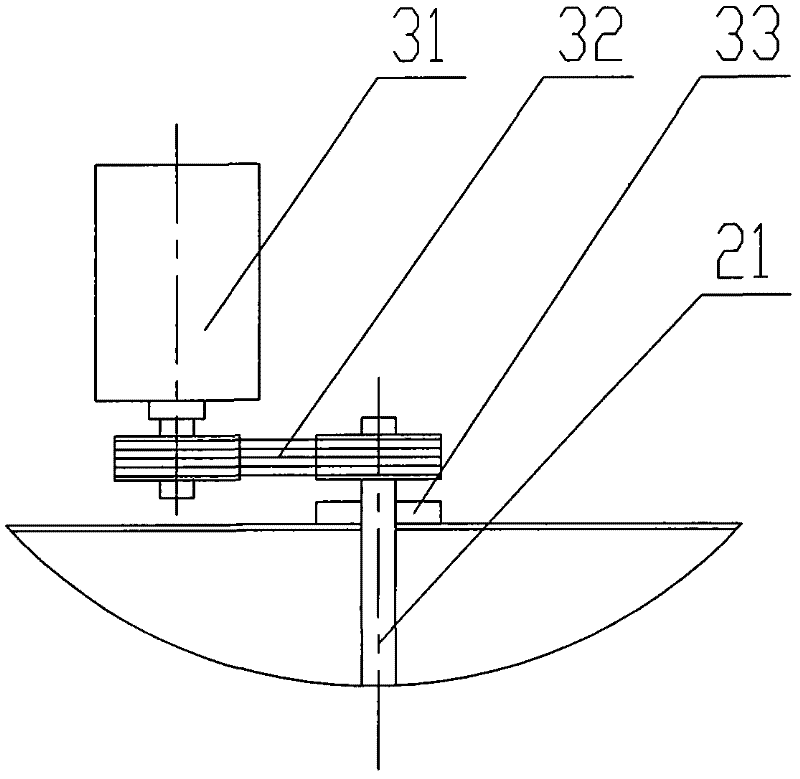

[0025] see figure 2 , The broken bag crushing device 2 is composed of a row of rollers, and each roller is assembled by a shaft assembly 21, a cylinder assembly 22 and a tooth piece 23, etc. The roller row of the bag breaking and crushing device 2 rotates under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com