Method for producing metal composite plate

A technology for metal clad panels and cladding equipment, used in chemical instruments and methods, layered products, lamination devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

[0016] A method of producing a metal composite panel, comprising the steps of:

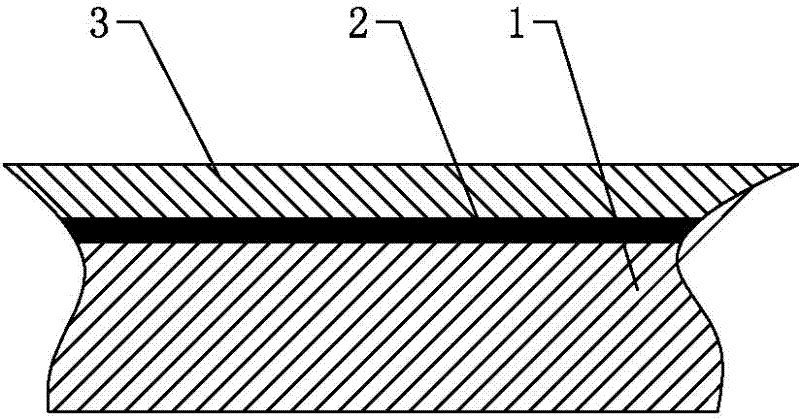

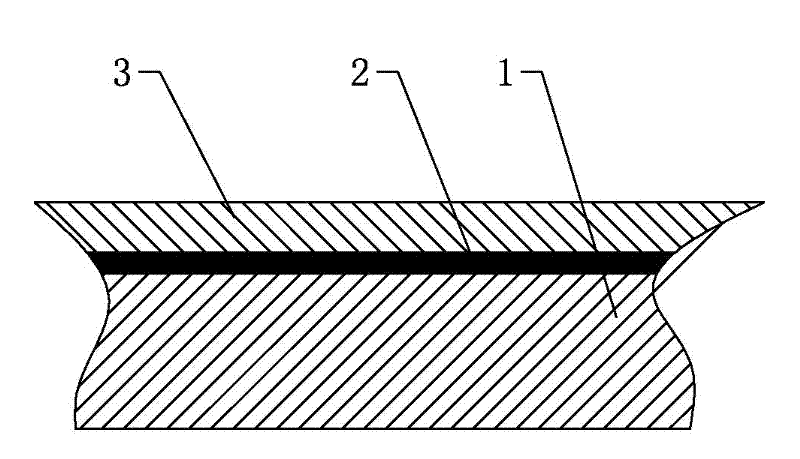

[0017] (1) Unwind the substrate 1 through the unwinding equipment, and then cut the head of the substrate 1 flat through the head cutting equipment. The unwinding equipment is an unwinding machine set at the most upstream of the production process. The material is unrolled by the unwinder, and the head cutting equipment is a head cutter installed downstream of the unwinder. The head cutter can cut the head of the substrate 1 flat to ensure that it is convenient to connect with the tail of the previous roll of substrate 1. ; The base material 1 can be selected in various ways, such as galvanized sheet or aluminum plate or cold-pressed plate, etc. The thickness of the base material 1 is 1.65-1.89mm.

[0018] (2) The finished base material 1 is jointed with the tail end of the last roll of base materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com