Flexible guide rail of mining elevator and arrangement method thereof

A technology of flexible guide rails and layout methods, applied in mining equipment, earth-moving drilling, shaft equipment, etc., can solve problems such as hidden dangers of elevator safe operation, high cost, and danger to the life safety of passengers, so as to reduce the investment cost of well construction and installation. And the effect of simple maintenance and increased safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

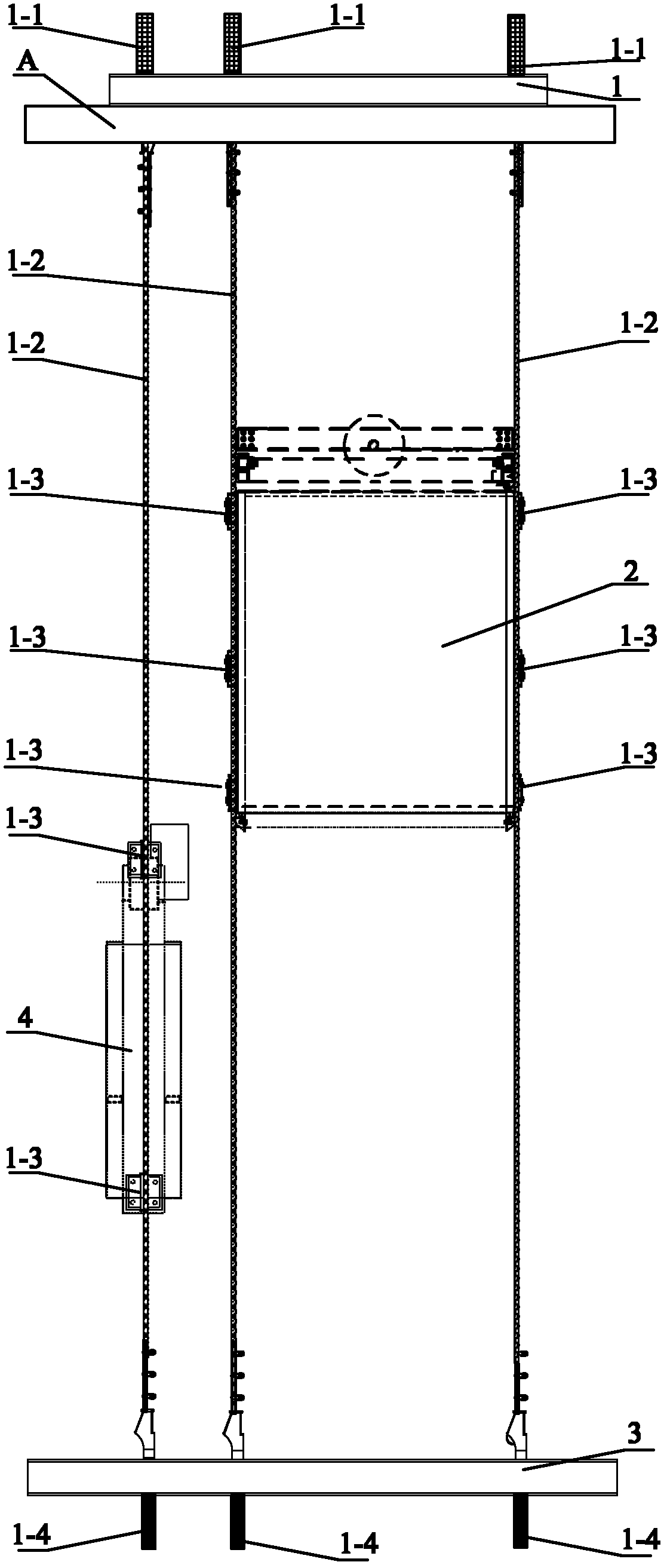

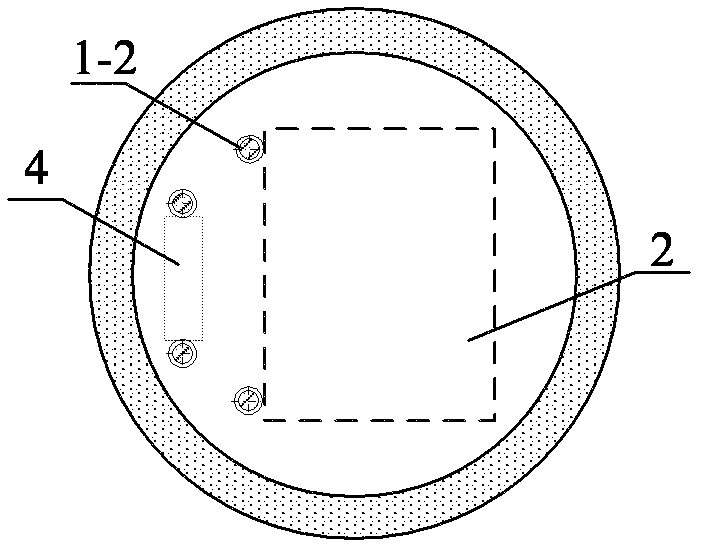

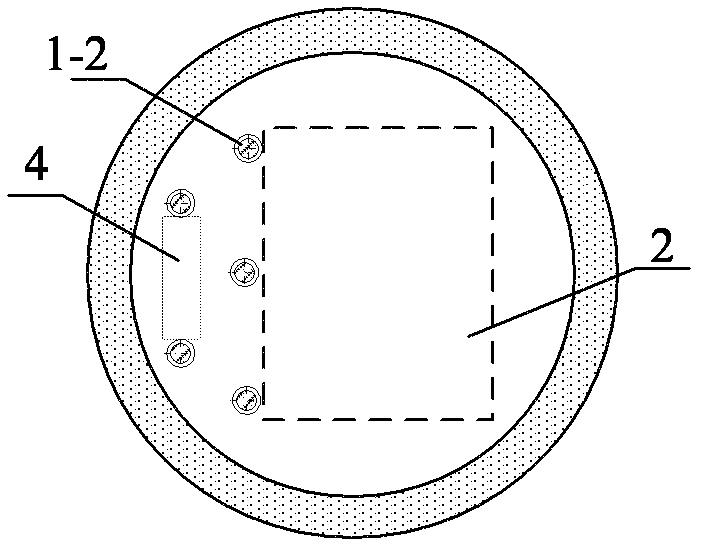

[0019] Such as figure 1 As shown, the mine elevator flexible guide rail of the present invention is mainly composed of the upper bearing beam 1 on the top platform A of the derrick and the lower bearing beam 3 of the underground pit and the steel wire rope guide rail 1-2 between the upper and lower bearing beams. Between the upper bearing beam 1 and the lower bearing beam 3, there are steel wire rope guide rails 1-2 for respectively fixing the car 2 and the counterweight 4, and the upper end of the steel wire rope guide rail 1-2 is tensioned by the The device 1-1 is connected and fixed. The tensioning device 1-1 is applied by hydraulic tensioning or spring pre-tensioning, or by the counterweight of the pit. The tensioning device 1-1 is mainly composed of a rope clamp and a hydraulic cylinder. A wire rope guide rail 1-2 is arranged in the middle of the rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com