Apparatus and process for preparing graphene by the technology of cavitating jet

A graphene technology, which is applied in the field of graphene preparation devices, can solve the problems of the limitation of preparation methods, the quality of graphene is not perfect, and cannot satisfy the mass production of graphene, etc., and achieves the simple and easy preparation process and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

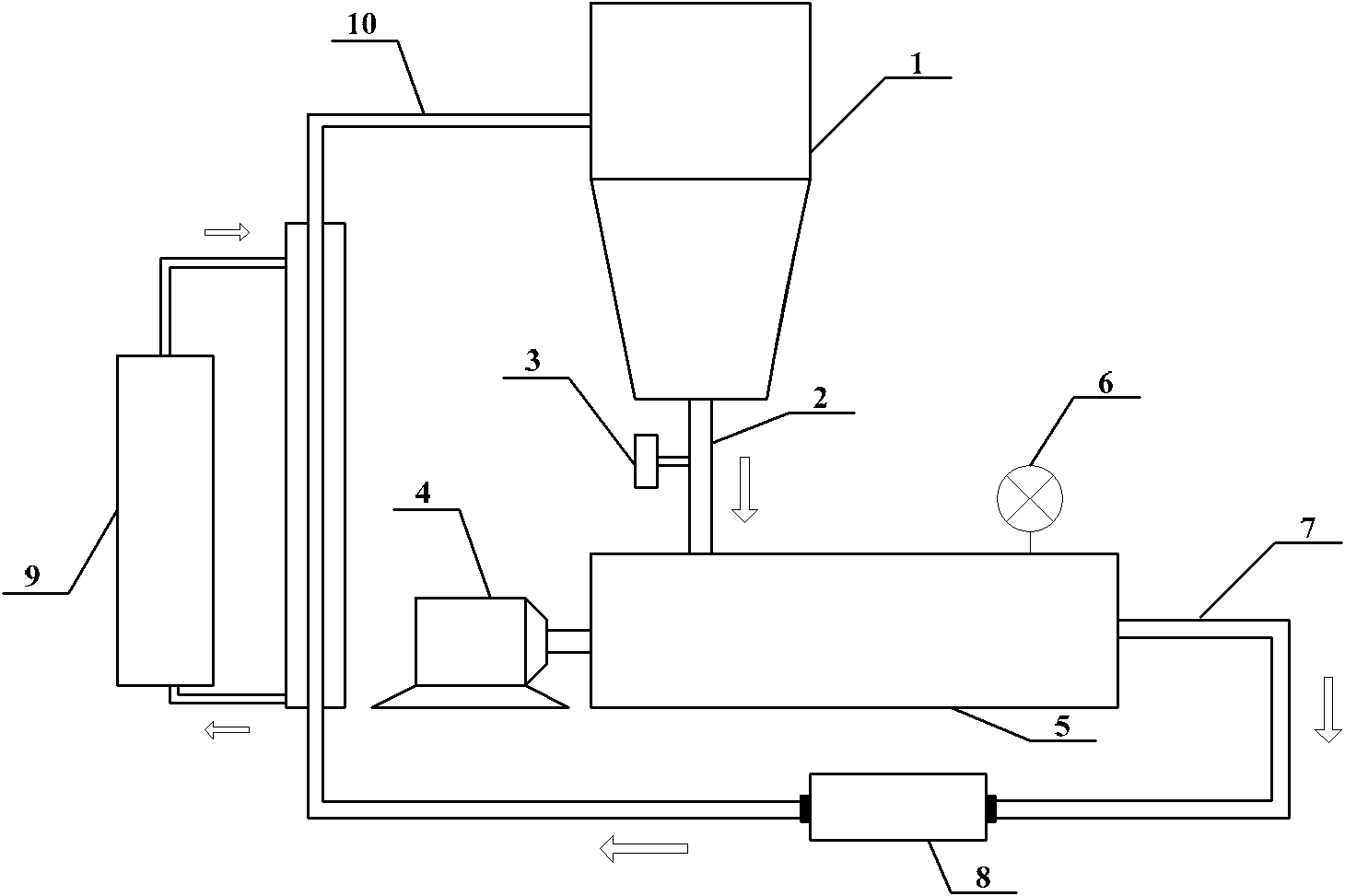

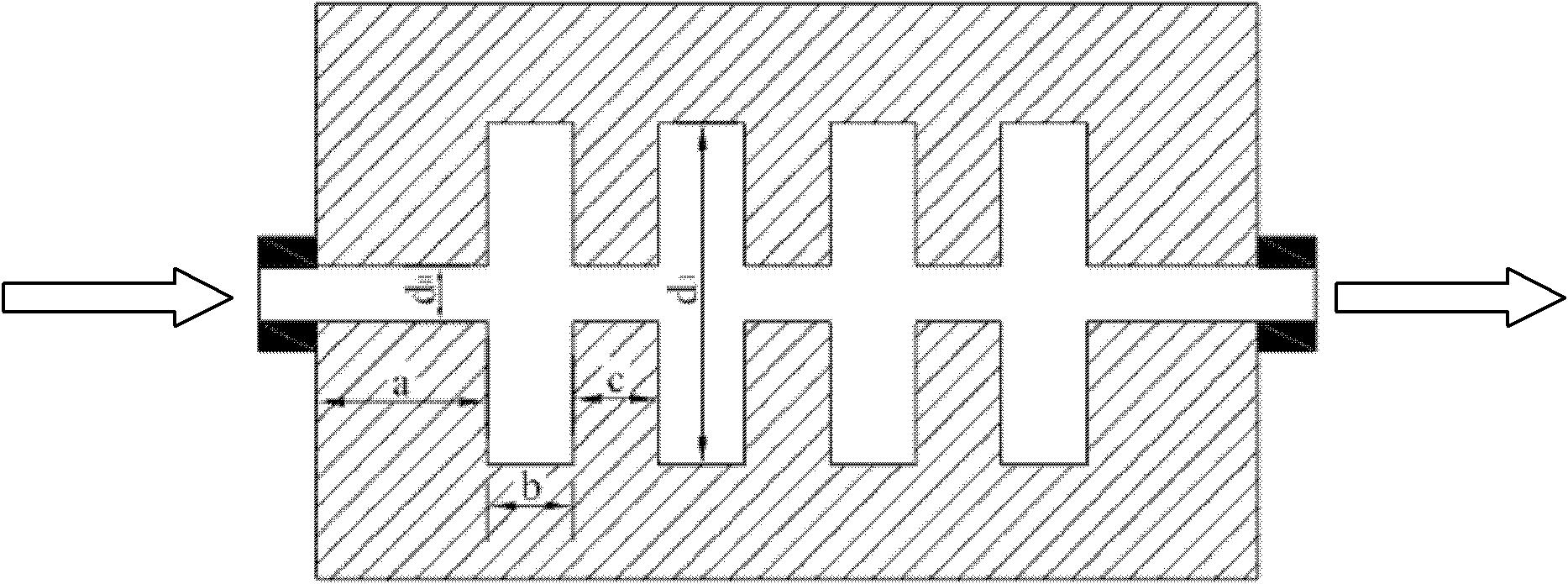

[0058] A jet cavitation device such as figure 1 As shown, the cavitation generator as figure 2 As shown, the process of preparing graphene by jet cavitation method is:

[0059] The first step: 1.9% graphite powder with an average particle size of 12 μm, 0.1% sodium carboxymethylcellulose modifier (CMC) and 98% water are prepared to prepare an aqueous graphite solution with good dispersion stability, and put it into the storage tank 1 in;

[0060] Step 2: Set the working pressure of the plunger pump 5 to 20Mpa, open the valve 3 at the water inlet pipe 2, the graphite aqueous solution enters the plunger pump 5 from the storage tank 1, and turn on the motor 4 to run the system, and the graphite aqueous solution is pressurized to the specified Pressure 20Mpa; The power of the motor 4 is 30KW;

[0061] The third step: the graphite aqueous solution after pressurization enters the cavitation generator 8 through the high-pressure pipe 7, and the graphite particles in the solution ...

Embodiment 2

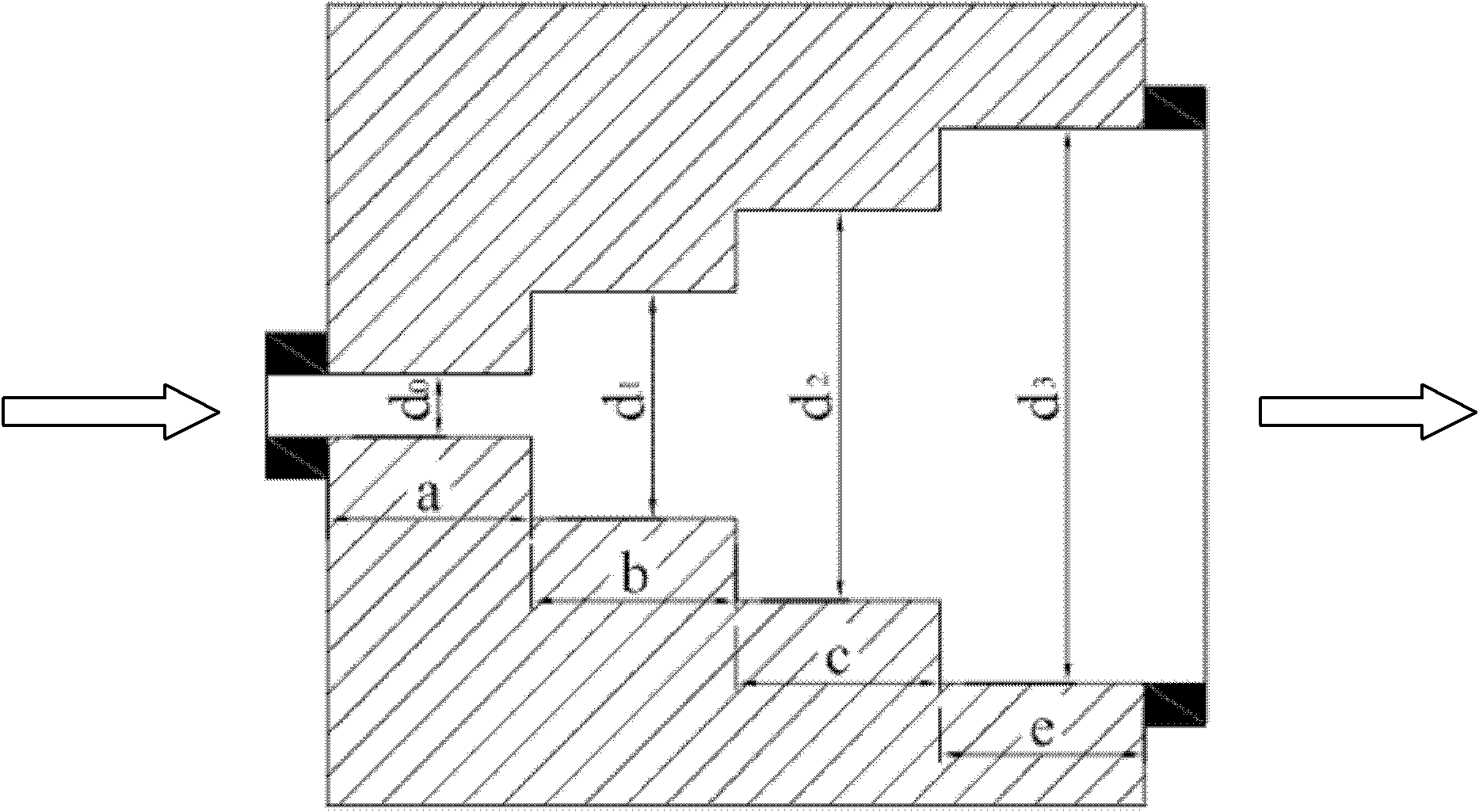

[0067] A jet cavitation device such as figure 1 As shown, the cavitation generator as image 3 As shown, the process of preparing graphene by jet cavitation method is:

[0068] The first step: 4.9% graphite powder with an average particle size of 25 μm, 3.1% sodium lauryl sulfate and 92% water are prepared to prepare an aqueous graphite solution with good dispersion stability, and put it into the storage tank 1;

[0069] Step 2: Set the working pressure of the plunger pump 5 to 40MPa, open the valve 3 at the water inlet pipe 2, the graphite aqueous solution enters the plunger pump 5 from the storage tank 1, and turn on the motor 4 to run the system, and the graphite aqueous solution is pressurized to the specified Pressure 40Mpa; The power of the motor 4 is 30KW;

[0070] The third step: the graphite aqueous solution after pressurization enters the cavitation generator 8 through the high-pressure pipe 7, and the graphite particles in the solution are peeled off under the act...

Embodiment 3

[0076] A jet cavitation device such as figure 1 As shown, the cavitation generator as figure 2 As shown, the process of preparing graphene by jet cavitation method is:

[0077] The first step: 9.1% graphite powder with an average particle size of 45 μm, 4.9% sodium lauryl sulfate and 86% water are prepared to prepare an aqueous graphite solution with good dispersion stability, and put it into the storage tank 1;

[0078] Step 2: Set the working pressure of the plunger pump 5 to 70MPa, open the valve 3 at the water inlet pipe 2, the graphite aqueous solution enters the plunger pump 5 from the storage tank 1, and turn on the motor 4 to run the system, and the graphite aqueous solution is pressurized to the specified Pressure 70Mpa; The power of the motor 4 is 30KW;

[0079] The third step: the graphite aqueous solution after pressurization enters the cavitation generator 8 through the high-pressure pipe 7, and the graphite particles in the solution are peeled off under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com