Aqueous compositions with polyvalent metal cations and dispersed polymers

A water-based composition and composition technology, applied in the direction of polishing composition, chemical instrument and method, coating, etc., can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

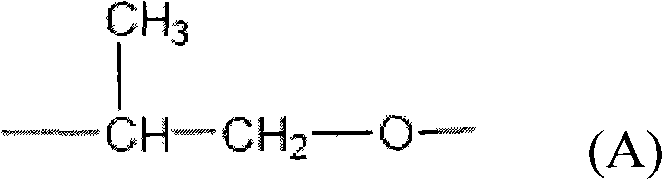

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: the preparation of latex polymer

[0086] Using standard techniques of aqueous emulsion polymerization, the polymers were prepared from the following monomer mixtures. The result of each polymerization is a dispersion of polymer particles in water with a pH of less than 7.

[0087] Table 1

[0088] MM1

Embodiment 2

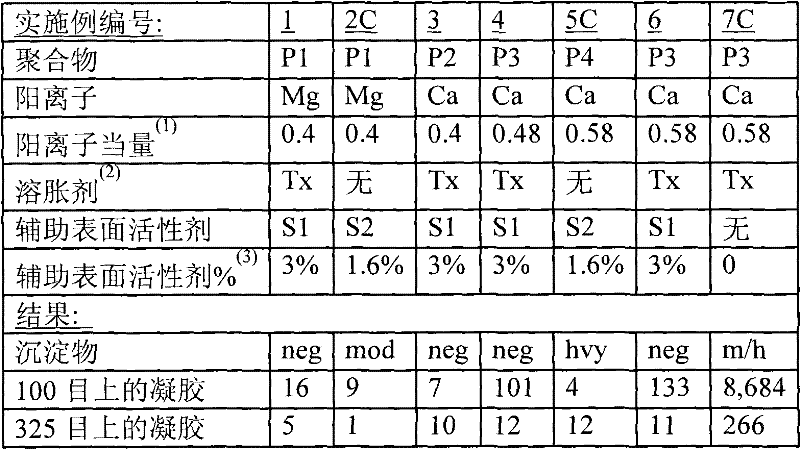

[0089] Embodiment 2: the preparation of premix:

[0090] The dispersion of polymer particles is mixed with a swelling agent and a cosurfactant. The cosurfactant and swelling agent are combined by shaking or stirring until an aqueous emulsion is formed. In the absence of a swelling agent, the co-surfactant was diluted with water to give a solids content of 22-24%. In the absence of cosurfactants, the swelling agent was added without further dilution. In all cases the aqueous polymer dispersion was at 50°C at the end of the polymerization. The aqueous polymer dispersion was cooled to 39°C, then the premix was gradually added at a steady state rate over 30 minutes and held for 20 minutes.

Embodiment 3

[0091] Embodiment 3: the preparation of follow-up mixture:

[0092] Add Ca or Mg cations. The resulting dispersion of polymer particles was neutralized with aqueous ammonia to a pH of 7.5-8.0 at 39°C over a period of 20 minutes. The polymer is held for an additional 20 minutes before calcium or magnesium is added. Add 2% dispersant to prepare 30% calcium hydroxide or magnesium oxide slurry. The slurry was then added to the polymer at 39°C over 30-60 minutes and the temperature was maintained for an additional 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com