Molecularly imprinted polymer specially combined with specified glycoprotein and preparation method and application of molecularly imprinted polymer

A technology of molecular imprinting and glycoprotein, which is applied in the photoplate making process of patterned surface, biological testing, material inspection products, etc., can solve the problems of many steps, poor anti-interference ability, long cycle, etc., and achieve simple preparation and anti-interference Strong ability and high specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of horseradish peroxidase (HRP) imprinted polymer

[0035] The preparation process of HRP molecularly imprinted polymer is as follows:

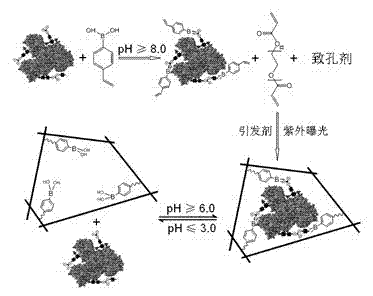

[0036] 1. Prepare the prepolymer solution, dissolve 0.005g p-vinylphenylboronic acid and 0.001g benzoin dimethyl ether in 400μl polyethylene glycol 200 (PEG200, average molecular weight 200), 100μl polyethylene glycol diacrylate ( PEGMA), phosphate buffer solution to adjust the pH value to 8.5, add 5 μl of 10 mg / ml HRP solution, and vortex for 2 minutes (the mass ratio of glycoprotein HRP to functional monomer p-vinylphenylboronic acid is 1: 100).

[0037] 2. Drop 100μl of pre-polymerization solution on the glass substrate derivatized with double bonds, attach a mask plate containing a specific structure, and expose to UV (365nm) for 40s. Remove the mask, soak the polymer in a mixed solution of ethanol / water (40% ethanol by volume) and vibrate for 30 minutes, then soak the polymer in acetonitrile / 10M phosphoric...

Embodiment 2

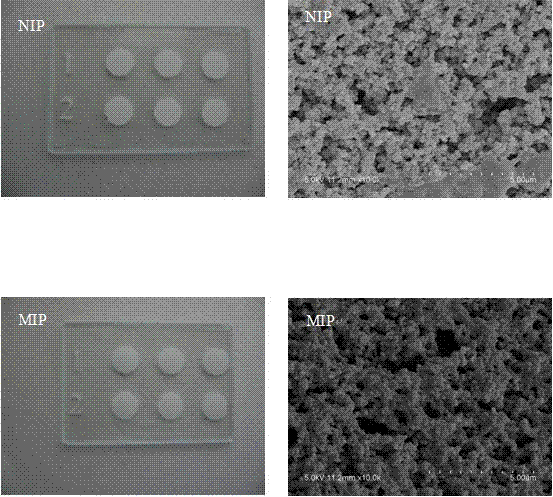

[0040] Example 2: Recognition of HRP by HRP imprinted polymers and comparison with non-imprinted polymers

[0041] The HRP imprinted polymer and non-imprinted polymer were used to identify HRP respectively, and 3,3',5,5'-tetramethylbenzidine (TMB) chromogenic method was used for naked eye detection:

[0042] 1. Prepare TMB chromogenic solution, sodium acetate 0.136g, citric acid 0.016g, 30% hydrogen peroxide 3μl, TMB 1.5mg, distilled water to 5ml.

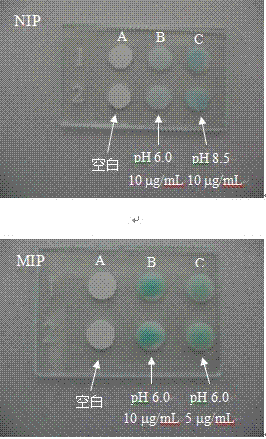

[0043] 2. In non-imprinted polymers ( image 3 Add 5 μl of water (pH 6.0), HRP aqueous solution (10 μg / ml, pH 6.0) and HRP phosphate solution (10 μg / ml, pH 8.5) dropwise on columns A, B, and C of A), and after 2 minutes add acetonitrile Rinse the non-imprinted polymer with a mixed solution of water / water (volume ratio 30:70) for 1 minute, dry the polymer, add 5 μl of TMB chromogenic solution dropwise to each point, and react in the dark for 10 minutes, and the polymerization after color development Objects recorded with a digital...

Embodiment 3

[0046] Example 3 Anti-interference ability of molecularly imprinted polymer

[0047] Using the same preparation steps as in Example 1, the pH value of the phosphate buffer solution in the formula was adjusted to 8 to prepare the HRP imprinted polymer. The recognition of HRP by HRP imprinted polymers in complex systems was observed by naked eyes using TMB chromogenic method:

[0048] 1. Prepare a complex solution: 1) dissolve 50 μg HRP, 1 mg fructose, 1 mg ovalbumin, 1 mg human hemoglobin, and 1 mg bovine serum albumin in 1 ml human serum; 2) dissolve 10 μg HRP, 1 mg fructose, 1 mg ovalbumin, 1 mg human Hemoglobin, 1 mg bovine serum albumin were dissolved in 1 ml human serum; 3) 5 μg HRP, 1 mg fructose, 1 mg ovalbumin, 1 mg human hemoglobin, 1 mg bovine serum albumin were dissolved in 1 ml human serum.

[0049] 2. Imprinted polymers in HRP ( Figure 4 Add 5 μl of water, serum, solution 1), solution 2), and solution 3) dropwise on columns 1, 2, 3, 4, and 5 of A), and after 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com