High brightness mechanical luminescent material and preparation method thereof

A mechanoluminescent, high-brightness technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of single luminescent color and single system, and achieve the effects of simple preparation method, low cost, and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

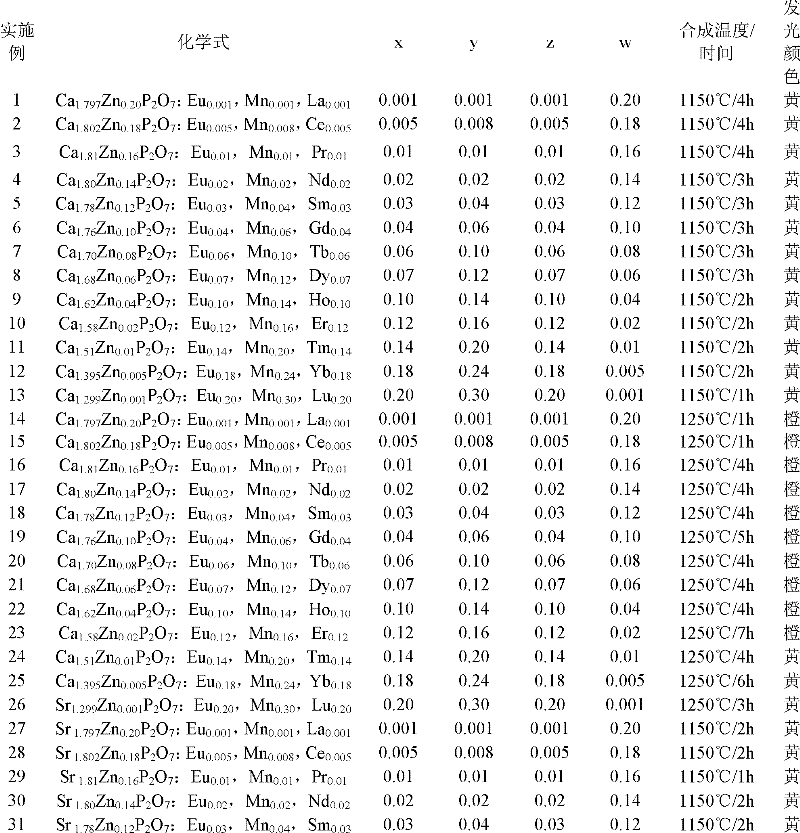

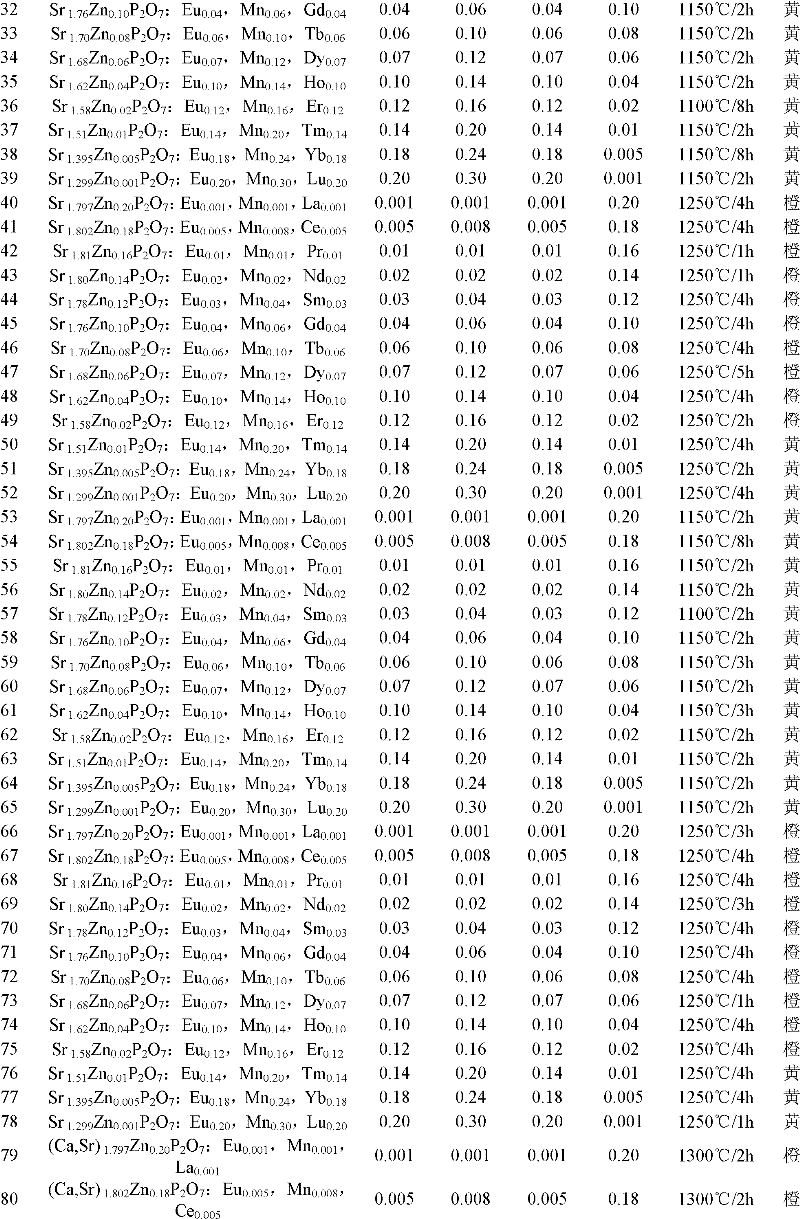

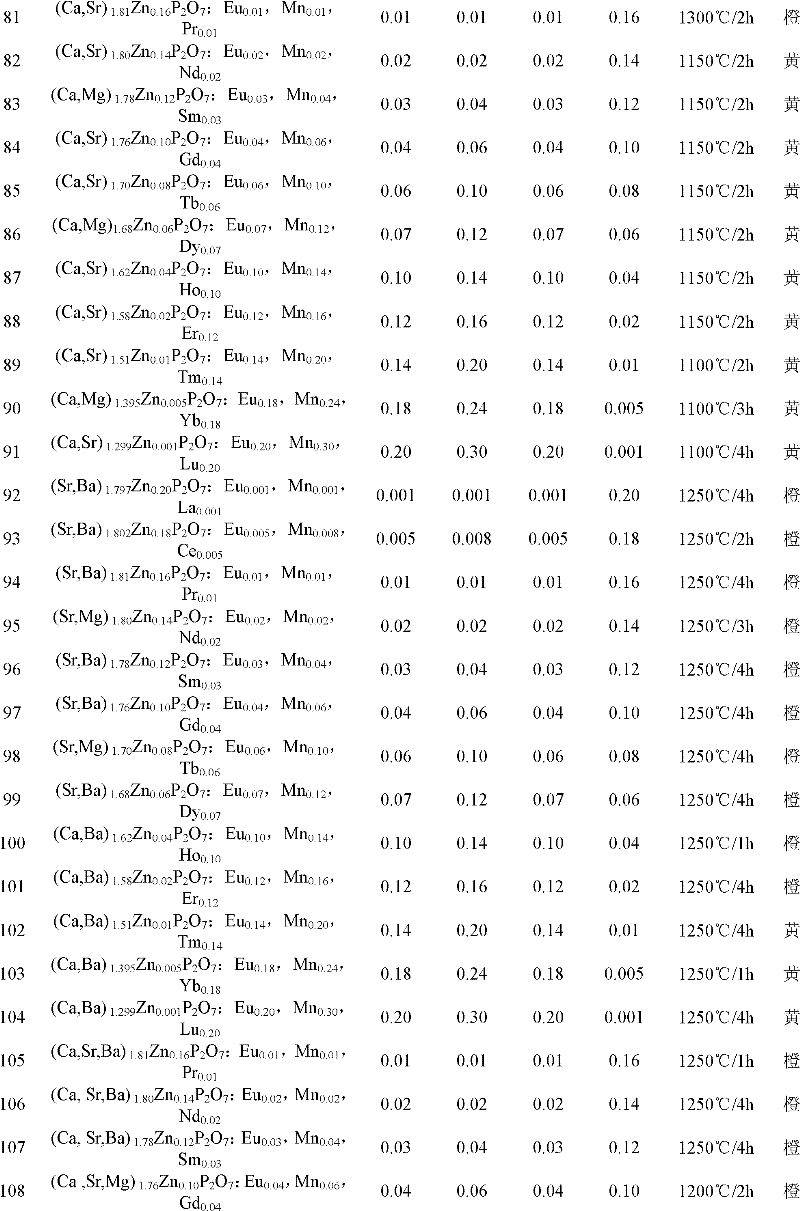

[0015] A method for preparing a high-brightness mechanical luminescence material, the method is realized by the following steps:

[0016] (1) The general formula of the material is M 2-x-y-z-w Zn w P 2 o 7 :Eu x , Mn y , Ln z The oxides, halides, carbonates or hydrogen phosphates of the elements are used as raw materials, weighed according to the stoichiometric ratio, thoroughly ground and mixed and pressed into tablets to obtain a mixture sample; the M represents one of Ca and Sr Or its combination, or any combination of Ca, Sr and Mg, or any combination of Ca, Sr and Ba; Ln represents La, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, Tm, Yb, One or any combination of Lu; the value range of x is: 0.0001≤x≤0.20, the value range of y is: 0.001≤y≤0.30, the value range of z is: 0<z≤0.20, the value range of w The value range is: 0<w≤0.20;

[0017] (2) Put the mixture sample obtained in step (1) into a crucible, put it into a high-temperature muffle furnace for roasting under reducin...

Embodiment 1

[0026] A high-brightness mechanical luminescent material whose general formula is M 2-x-y-z-w Zn w P 2 o 7 :Eu x , Mn y , Ln z , wherein when M=Ca, Ln=La, x=0.001, y=0.001, z=0.001, w=0.20 in the general chemical formula, the prepared molecular formula is Ca 1.797 Zn 0.20 P 2 o 7 :Eu 0.001 , Mn 0.001 , La 0.001 mechanoluminescent materials.

[0027] Weigh 2.4440g CaHPO according to stoichiometric ratio 4 , 0.2680g (NH 4 ) 2 HPO 4 , 0.0035gEu 2 o 3 , 0.0012g MnCO 3 , 0.0035g La 2 o 3 , 0.1628g ZnO, after the weighed raw materials are fully ground and mixed, pressed into tablets, placed in a high-purity corundum crucible, and roasted in a high-temperature muffle furnace under a carbon monoxide reducing atmosphere, roasted at 1150 ° C for 4 hours, cooled , grinding and washing to obtain the yellow photomechanical luminescent material Ca 1.797 Zn 0.20 P 2 o 7 :Eu 0.001 , Mn 0.001 , La 0.001 .

Embodiment 2

[0029] A high-brightness mechanical luminescent material whose general formula is M 2-x-y-z-w Zn w P 2 o 7 :Eu x , Mn y , Ln z , wherein when M=Ca, Ln=Ce, x=0.005, y=0.008, z=0.005, w=0.18 in the general chemical formula, the prepared molecular formula is Ca 1.802 Zn 0.18 P 2 o 7 :Eu 0.005 , Mn 0.008 , Ce 0.005 mechanoluminescent materials.

[0030] Weigh 2.4507g CaHPO according to stoichiometric ratio 4 , 0.2614g (NH 4 ) 2 HPO 4 , 0.0176gEu 2 o 3 , 0.0092g MnCO 3 , 0.0086g CeO 2, 0.1465g ZnO, after the weighed raw materials are thoroughly ground and mixed, pressed into tablets, placed in a platinum crucible, and roasted in a high-temperature muffle furnace under an ammonia reducing atmosphere, roasted at 1150°C for 4 hours, cooled, After grinding and washing, the yellow photomechanical luminescence material Ca 1.802 Zn 0.18 P 2 o 7 :Eu 0.005 , Mn 0.008 , Ce 0.005 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com