Combustion system of vortex-type diesel engine

A combustion system and diesel engine technology, applied in the direction of combustion engines, mechanical equipment, engine components, etc., can solve the problems of weakened vortex intensity, inability to achieve the best mixing effect of fuel and gas, and increase losses, etc., to achieve enhanced vortex intensity, gas Smooth flow and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

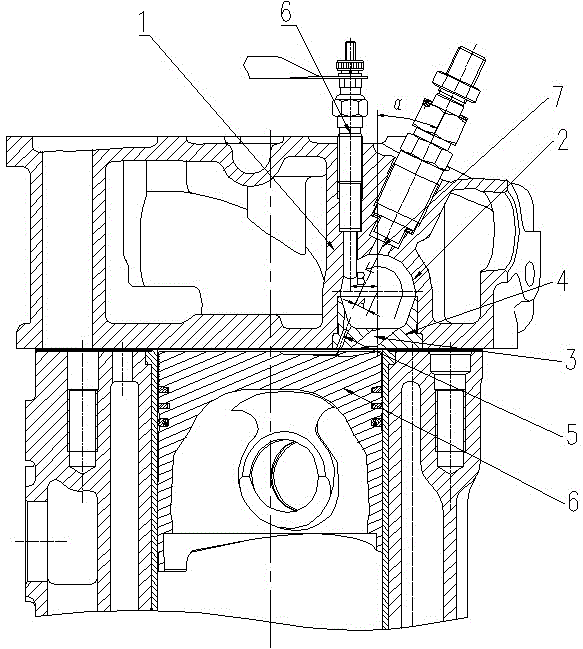

[0027] figure 1 The combustion system of a vortex diesel engine is shown, which includes the main combustion chamber and the vortex chamber:

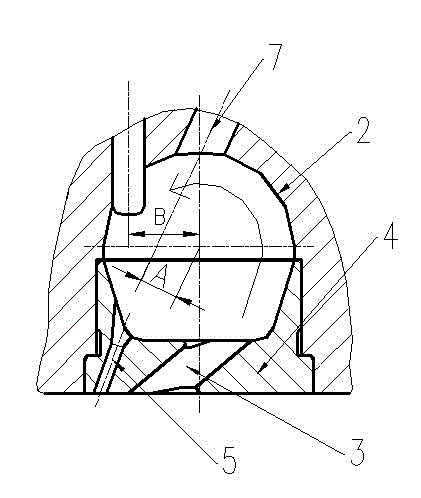

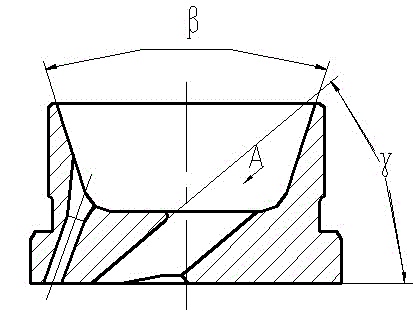

[0028] The vortex chamber as figure 2 As shown, it is surrounded by an upper chamber 2 formed by the inner wall of the cylinder head 1 and a bottom insert 4 with a groove. The upper chamber 2 in this embodiment is hemispherical. The upper chamber 2 communicates with the fuel injection hole 7, and a pintle type single-hole fuel injector 8 is connected in the fuel injection hole, and the included angle α between the fuel injection hole 7 and the axis of the swirl chamber is 23 °-27°. The upper part of the vortex chamber is also communicated with glow plugs 10 , and the multi-cylinder glow plugs 10 are connected together through conductive plates 9 . The distance B between the axis of the glow plug 10 and the axis of the vortex chamber is 10-12mm. The inner wall of the insert 4 is a rounded truncated cone, and its cone angle β is 30°-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com