Exhausting and sound deadening structure of refrigerator compressor

A compressor exhaust and sound-absorbing structure technology, which is applied to mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of reduced efficiency, increased compressor shell temperature, and high heat transfer coefficient, and achieves temperature reduction , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

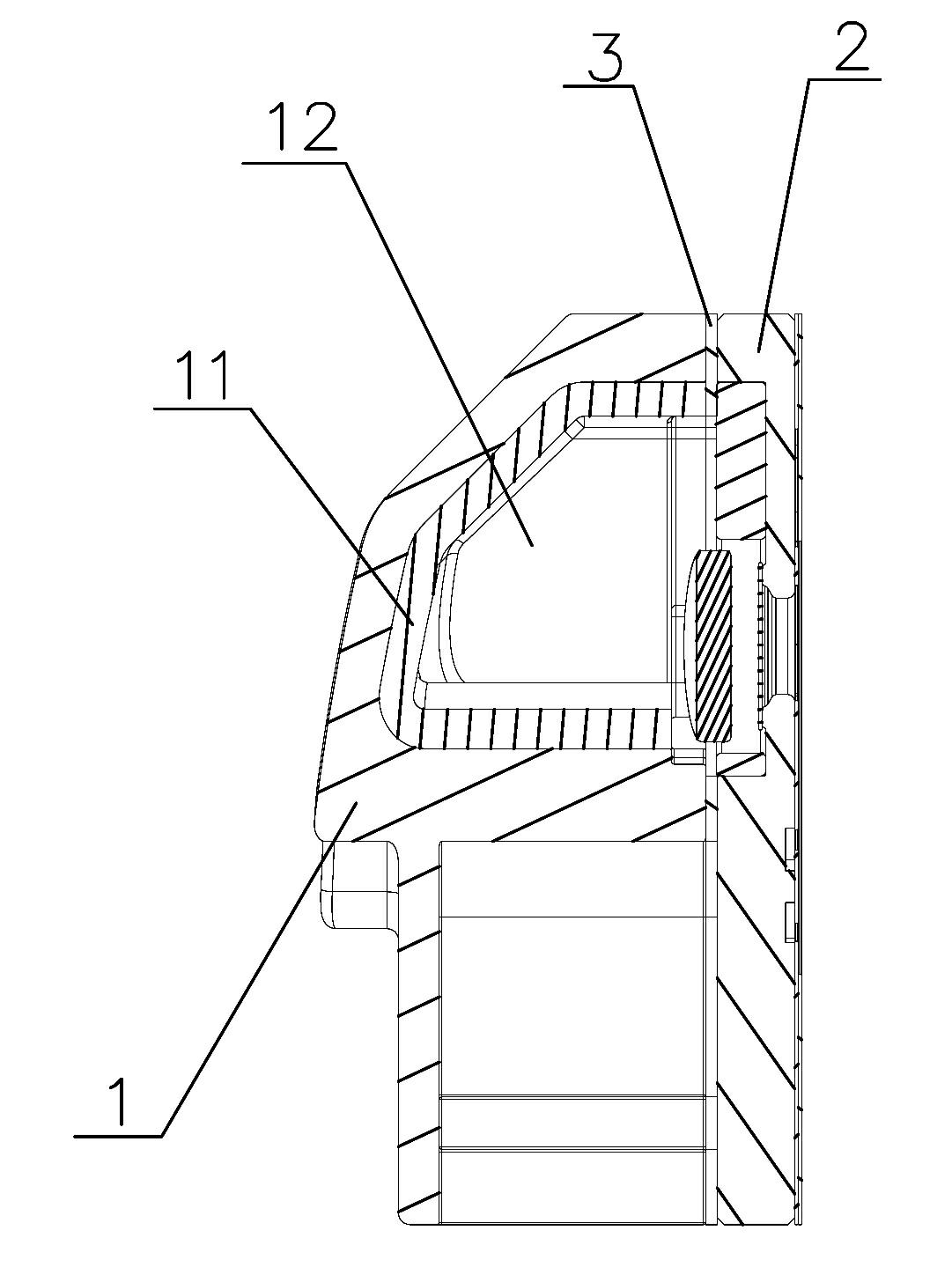

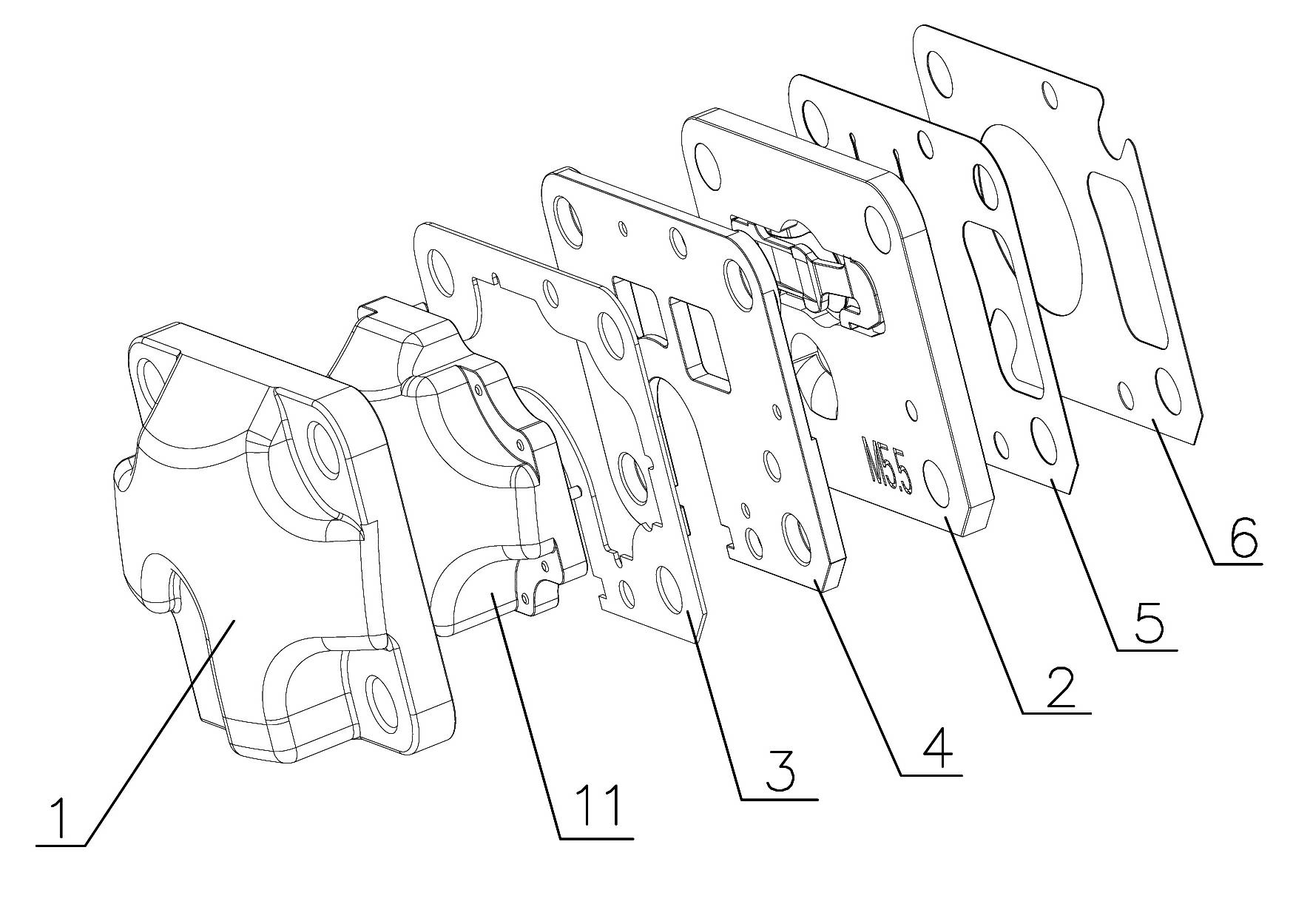

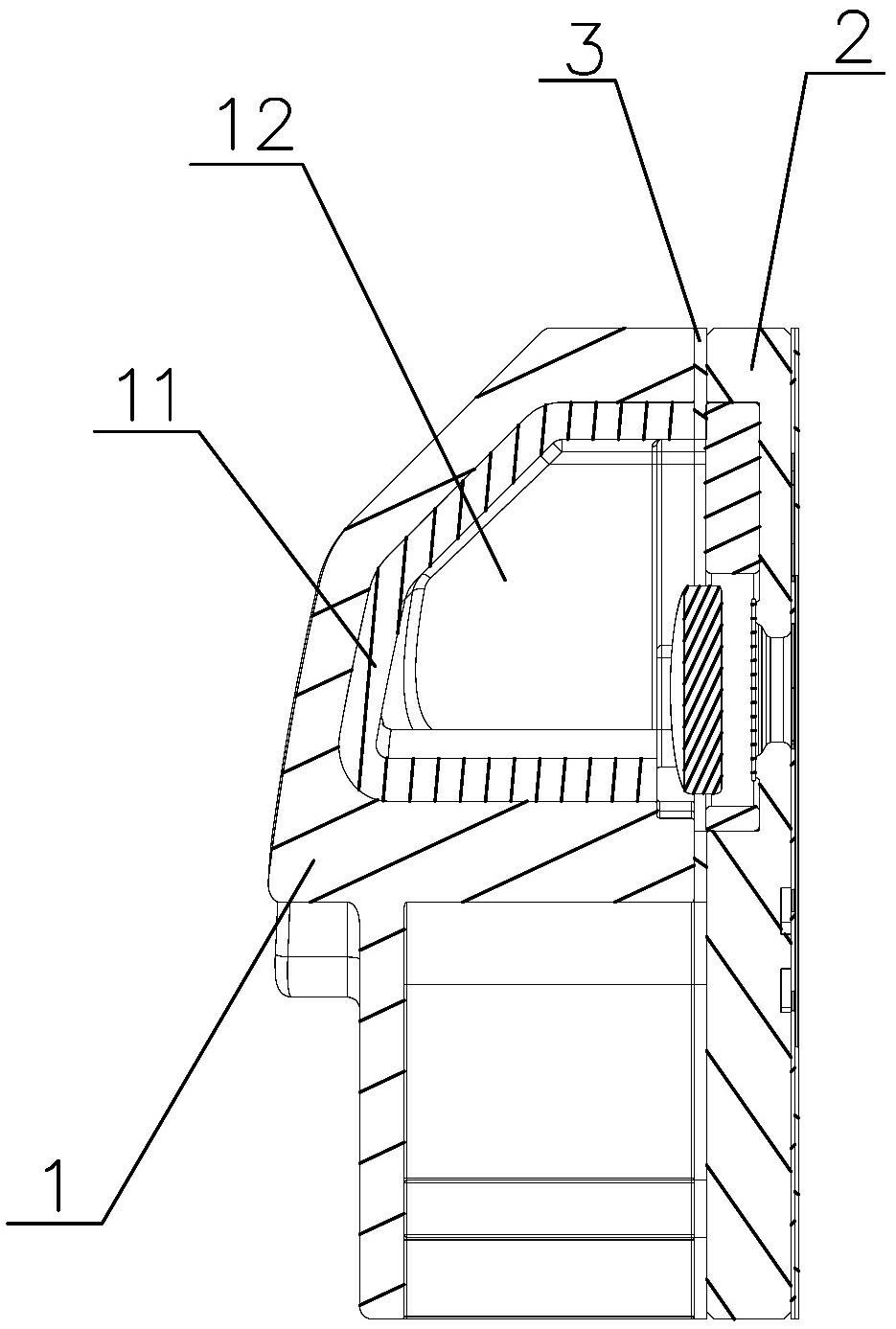

[0013] refer to Figure 1 ~ Figure 2 1. Refrigerator compressor exhaust silencer structure, which includes a cylinder head 1 with a silencer chamber 12 and a valve plate 2 connected to the end face of the silencer chamber 12. The inner surface of the silencer chamber 12 is provided with a heat insulating layer.

[0014] As a further preferred embodiment, the muffler cavity 12 is provided with an inner liner 11 attached to its inner surface, and the inner liner 11 is a polymer material member with poor thermal conductivity, thereby forming the heat insulation layer. Of course, in the actual assembly, more suitable spacers or gaskets can be added according to the air tightness, such as figure 2 As shown, add gasket 3 and spacer 4 between valve piece 2 and inner bushing 11, install suction valve piece 5 and valve plate gasket 6 between valve piece 2 and the cylinder seat to be connected, etc. etc., these are all common structures of the suction and discharge parts of conventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com