Deceleration motor device

A technology of geared motors and electromagnetic units, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor alignment precision, long shaft length, inconvenience, etc., and is conducive to the thinning of finished products and the promotion of assembly The effect of precision and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, method, steps, features and characteristics of the geared motor device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Its effect is described in detail below.

[0040] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

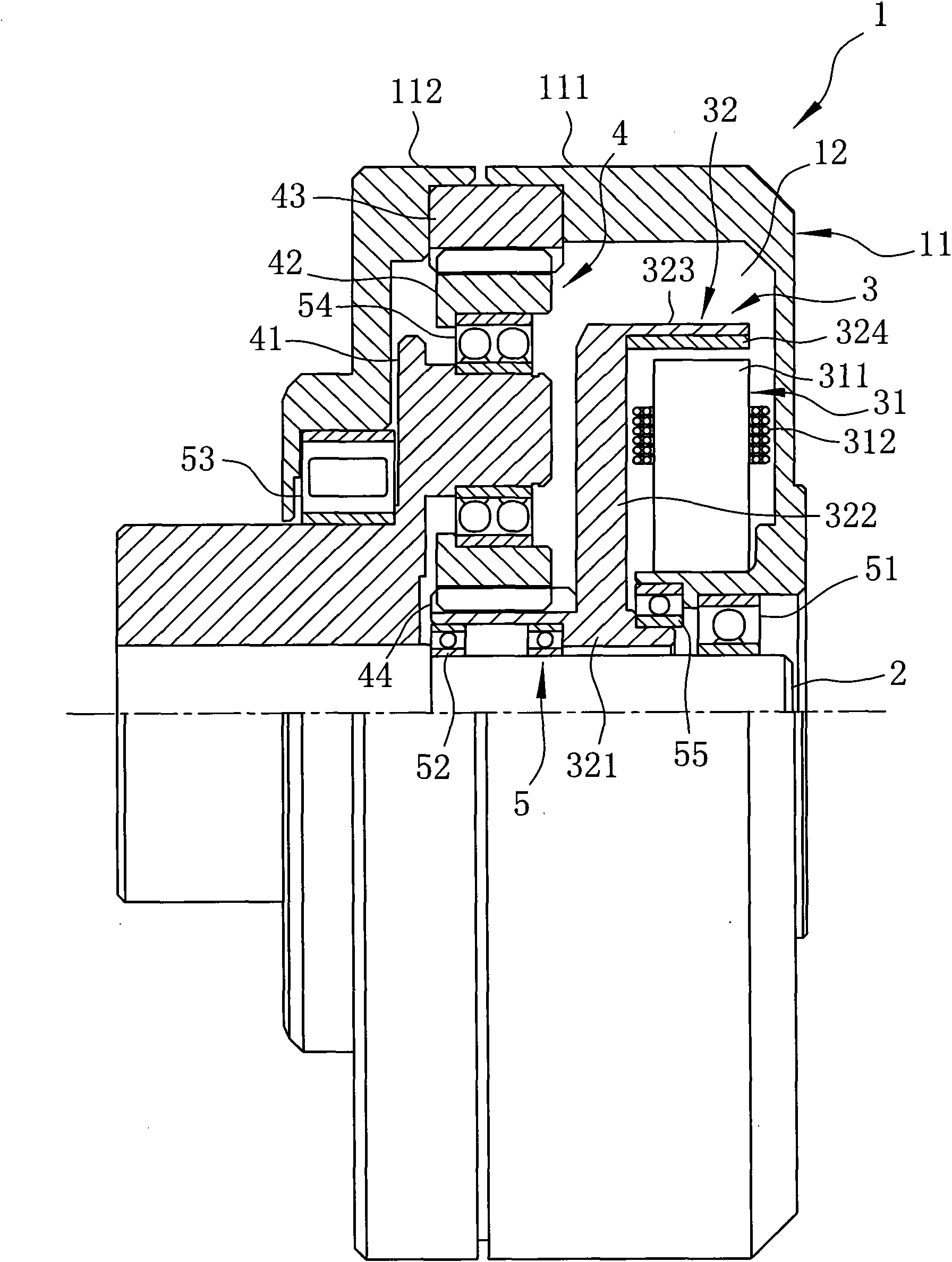

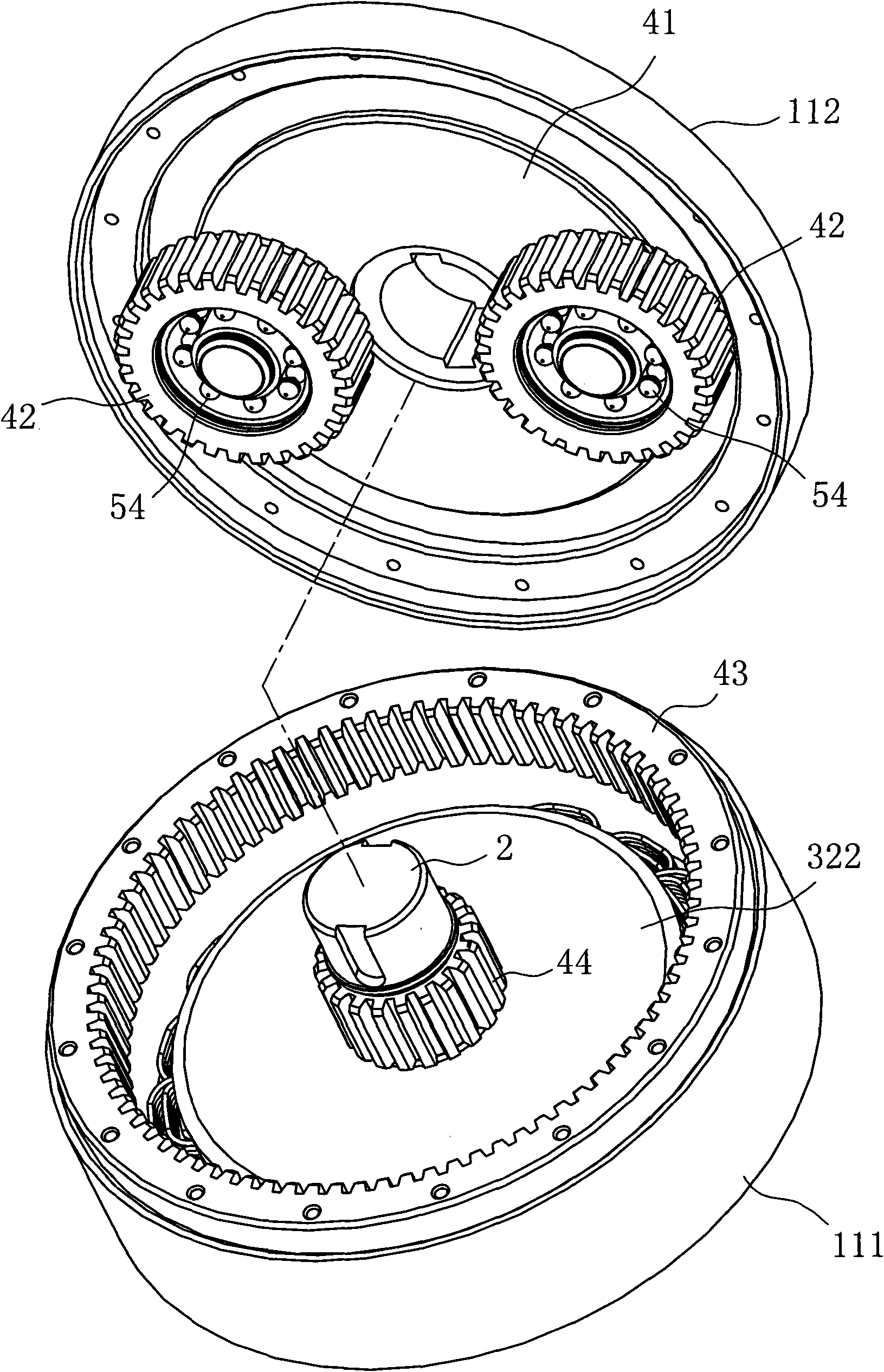

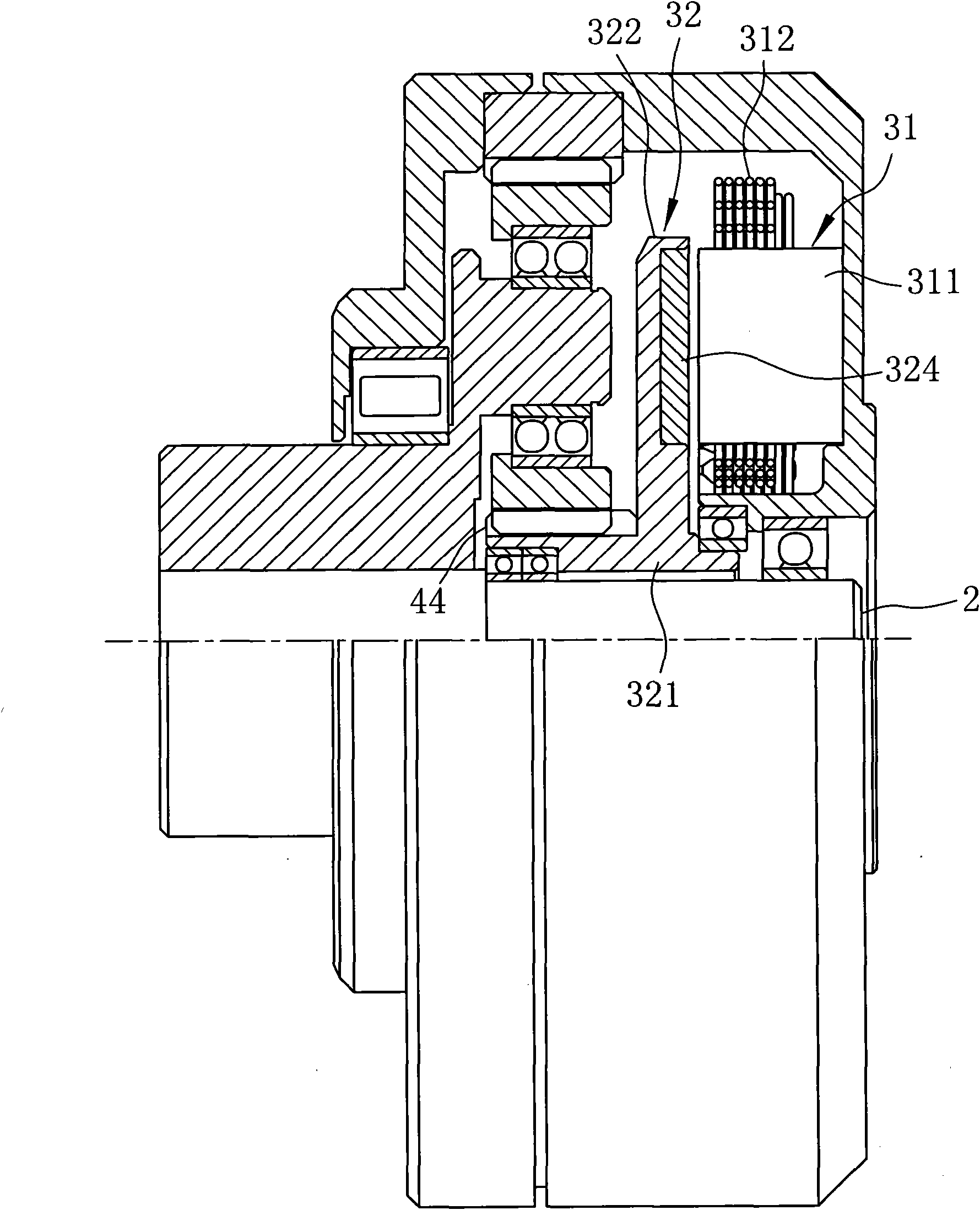

[0041] refer to figure 1 , and refer to figure 2 , The first preferred embodiment of the geared motor device of the present invention includes a housing unit 1 , a rotating shaft 2 , an electromagnetic unit 3 , a single-stage planetary gear unit 4 , and a bearing unit 5 . It should be noted that since the structure of this embodiment is a symmetrical shape, therefore fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com