Linear switch magnetic flux permanent magnet motor with low location force and high thrust

A technology of permanent magnet motor and switching magnetic flux, which is applied in the direction of electric components, electrical components, electromechanical devices, etc. It can solve the problems of unfavorable linear motor promotion and application, large thrust fluctuation, and large number of permanent magnets, etc., to achieve good heat dissipation and Effects of cooling, improving output and service life, reducing magnetic field harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

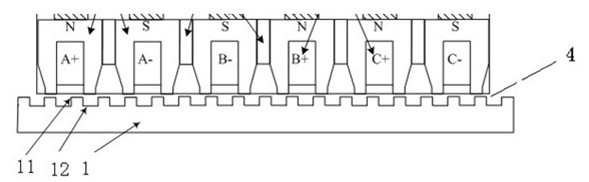

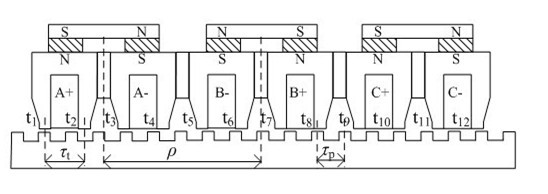

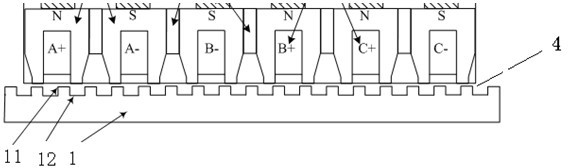

[0021] A novel linear plate type switched flux permanent magnet motor according to the present invention, comprising a primary iron core 21, a permanent magnet 22, a magnetically conductive bridge 24, a non-magnetically conductive spacer 23, a three-phase winding 3, a secondary mover 1 and a gas gap 4, such as figure 1 . The whole motor has a flat plate structure, and two permanent magnets with opposite magnetization directions are placed between two U-shaped cores in the same phase and the two ends of the magnetic bridge to form a closed magnetic circuit. The primary three-phase winding is embedded in the U-shaped slot of the primary iron core in the form of single-layer concentrated winding, and the air gap is located between the primary and secondary of the motor. The primary iron core can be made of silicon steel sheets, and the secondary stator air gap side is a U-shaped pole and slot structure with the same interval, which can be processed from a whole piece of alloy w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com