Composite composition for solid propellants including a ferrocene derivative and a submicronic aluminum charge, solid propellant, and load

A ferrocene derivative, solid propellant technology, applied in non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve problems such as increasing the sensitivity of burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

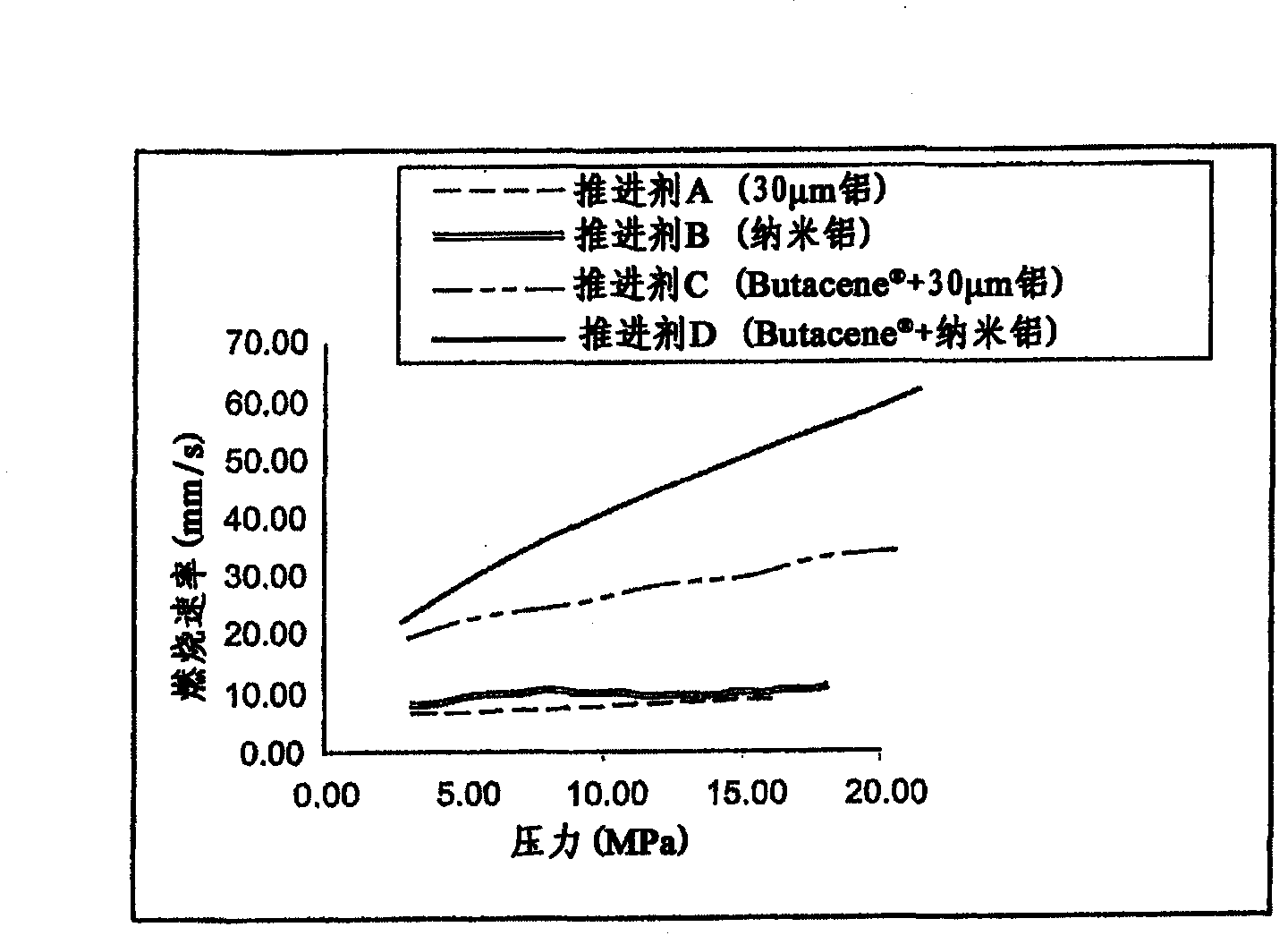

[0054] Table 2 below gives the characteristics and properties of the compositions and propellants A, B, C and D. These four compositions contained ammonium perchlorate oxidizing charge, aluminum charge, liquid polyol polymer, plasticizer (dioctyl azelate), crosslinking agent and known additives, and for composition C and D, also containing a ferrocene combustion catalyst: Butacene . Although compositions A and B are not strictly comparable to compositions C and D for what they have in common, the magnitudes given reveal the advantages of the invention.

[0055] Composition A is a prior art conventional composition of the type used in space applications. It does not contain ferrocene derivatives and contains micron aluminum with a D-median value of 30 μm.

[0056] Composition B is of the same type as Composition A. It differs from composition A primarily in that the aluminum particle size is submicron.

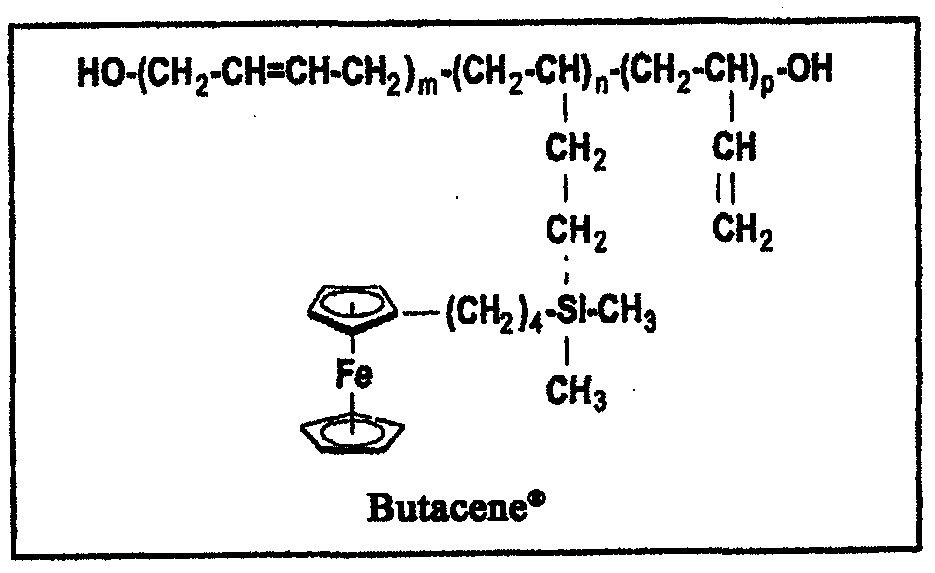

[0057] Composition C contains a ferrocene derivative (called Butacen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com