Surface treating agent for metallic materials

A technology for surface treatment agents and metal materials, applied in metal material coating technology, anti-corrosion coatings, coatings, etc., can solve problems such as the inability to replace surface-treated steel plates and the inability to inhibit the dissolution of metal compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

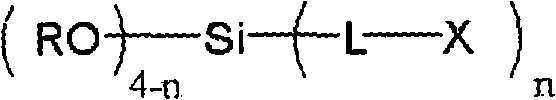

Method used

Image

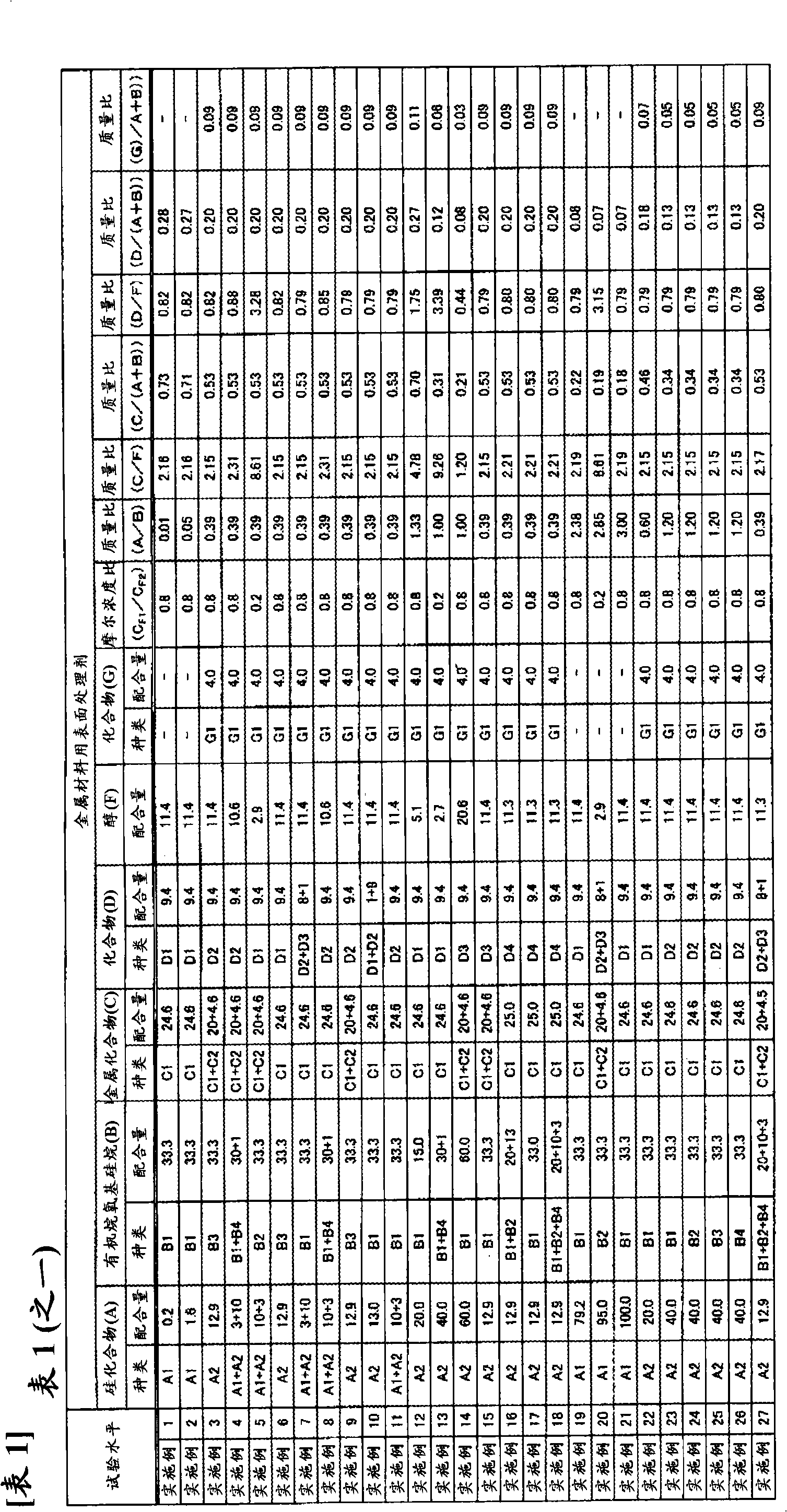

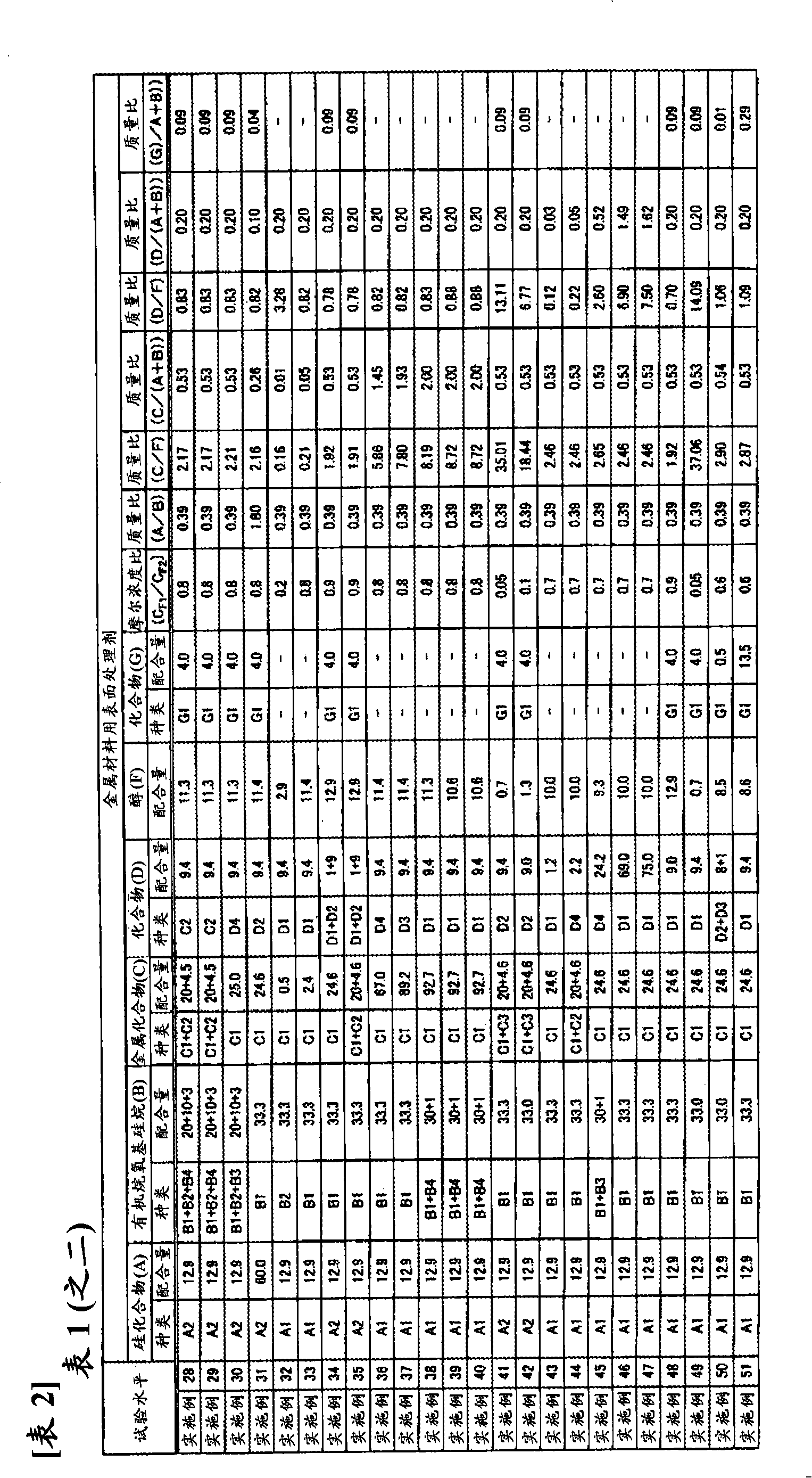

Examples

preparation example Construction

[0141] The preparation method of the surface treatment agent for metal materials of the present invention is not particularly limited. For example, the silicic acid compound (A), organoalkoxysilane (B), metal compound (C), phosphoric acid compound and / or fluorine compound (D) and water (E) can be fully mixed using a mixer such as a mixer. Mix to make.

[0142]

[0143] The surface treatment method using the surface treatment agent for metal materials of the present invention is not particularly limited, but the following surface treatment methods are preferred: the above-mentioned surface treatment agent for metal materials is coated on the surface of the metal material, heated and dried, and then applied to the metal material. The amount of film formed on the surface is 2 to 1000 mg / m in terms of Si adhesion 2 of the film.

[0144] Hereinafter, this surface treatment method will be described.

[0145] Before coating, if necessary, the metal material may be pretreated for...

Embodiment

[0157] Hereinafter, the effects of the present invention will be described through examples and comparative examples, but this example is merely an example for explaining the present invention and does not limit the present invention.

[0158] 1. How to make the test board

[0159] (1) Test materials (materials)

[0160] The following commercially available materials were used as test materials.

[0161] (i) Galvanized steel sheet (EG): plate thickness 0.8mm, weight per unit area = 20 / 20(g / m 2 )

[0162] (ii) Hot-dip galvanized steel sheet (GI): plate thickness 0.8mm, weight per unit area = 60 / 60(g / m 2 )

[0163] (iii) Alloyed hot-dip galvanized steel sheet (GA): plate thickness 0.8 mm, weight per unit area = 40 / 40 (g / m 2 )

[0164] In addition, the weight per unit area represents the weight per unit area on the main surface of each steel plate. For example, in the case of electro-galvanized steel sheets, it is 20 / 20 (g / m 2 ), refers to the two sides of the steel plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com