c-shaped nail making machine

A nailing machine and nailing technology, applied in the direction of nails, mechanical equipment, connecting components, etc., can solve the problems of low degree of automation, complex overall structure, unreasonable design, etc., and achieve good working stability, stable and reliable connection, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

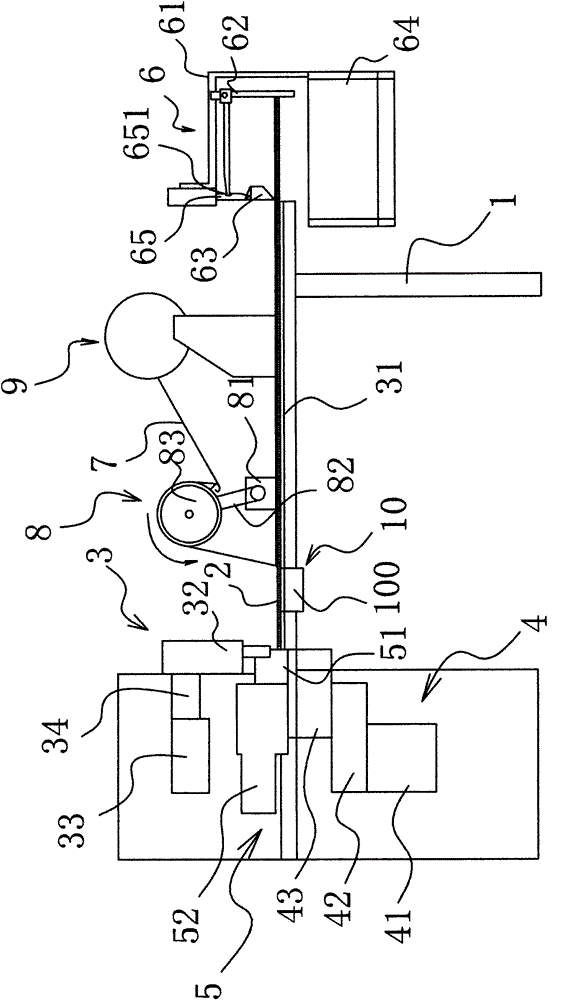

[0016] Such as figure 1 As shown, the C-shaped nail making machine includes a frame 1, on which a forming mechanism 3 capable of making nail-making materials into a C-shaped nail 2 is provided, and one side of the forming mechanism 3 is provided with a Mechanism 3 conveys feeding mechanism 4 for nail-making materials, and a nail pushing mechanism 5 for pushing C-shaped nails 2 is also provided on one side of forming mechanism 3 . The forming mechanism 3 includes a guide rail 31 on which the C-shaped nails 2 can be arranged and transported. The cross-section of the upper half of the guide rail 31 is arc-shaped, and a forming fixture capable of lifting is provided above one end of the guide rail 31. 32, the forming fixture 32 is connected with the forming driver 33 through the cam transmission structure 34, and the nail pushing mechanism 5 includes a nail pushing body 51 located at one end of the guide rail 31, and the nail pushing body 51 is connected with the nail pushing driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com