Production process of asphalt pavement fabric based on thermal recycling of asphalt pavement old materials

A technology of asphalt pavement and production process, which is applied in the direction of roads, roads, and on-site coagulation pavement, can solve the problems of high cost, low service life and low efficiency, and achieves good environmental protection effect, low cost and scientific method. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

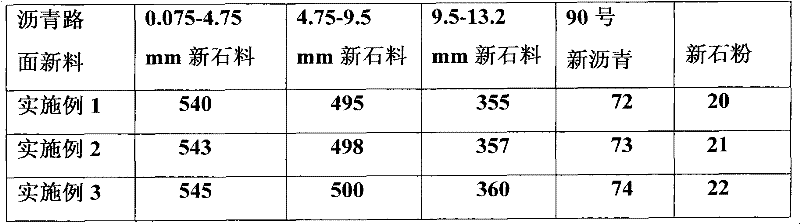

[0047] The present invention will be further described below using the embodiments shown in the accompanying drawings.

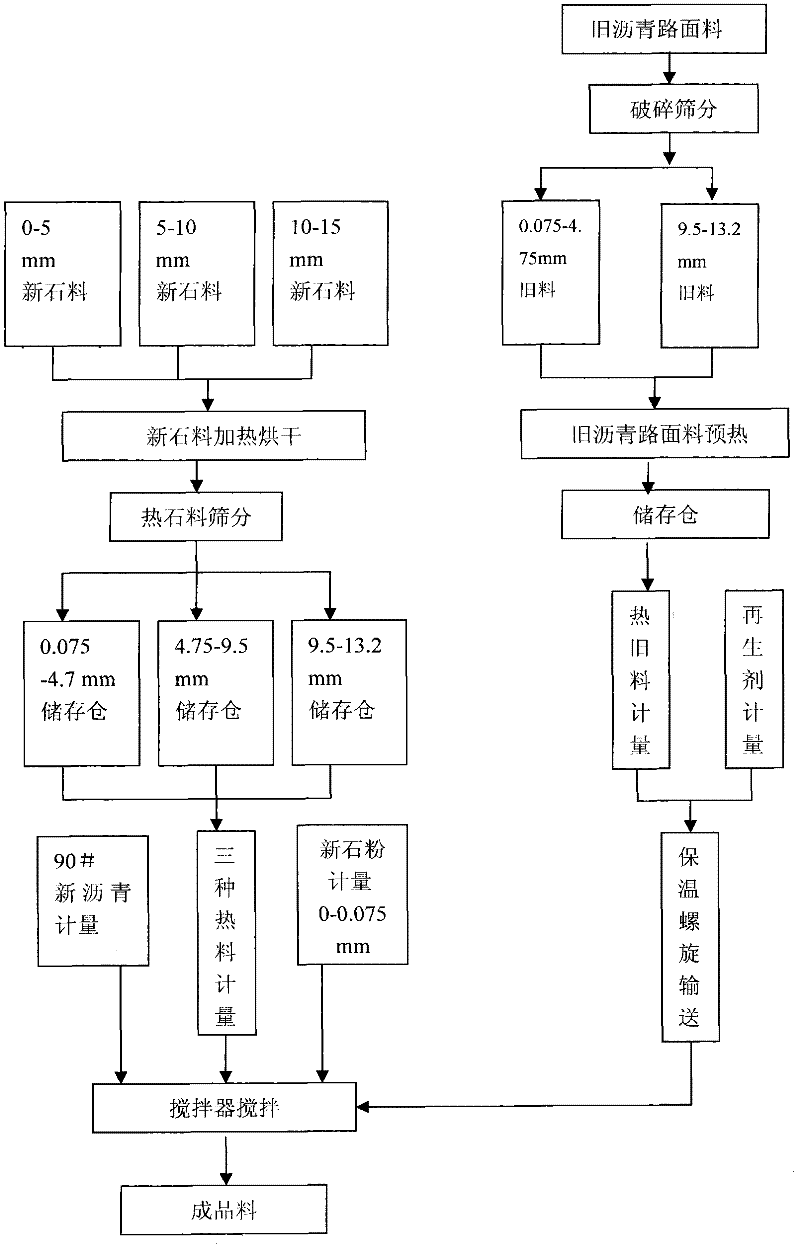

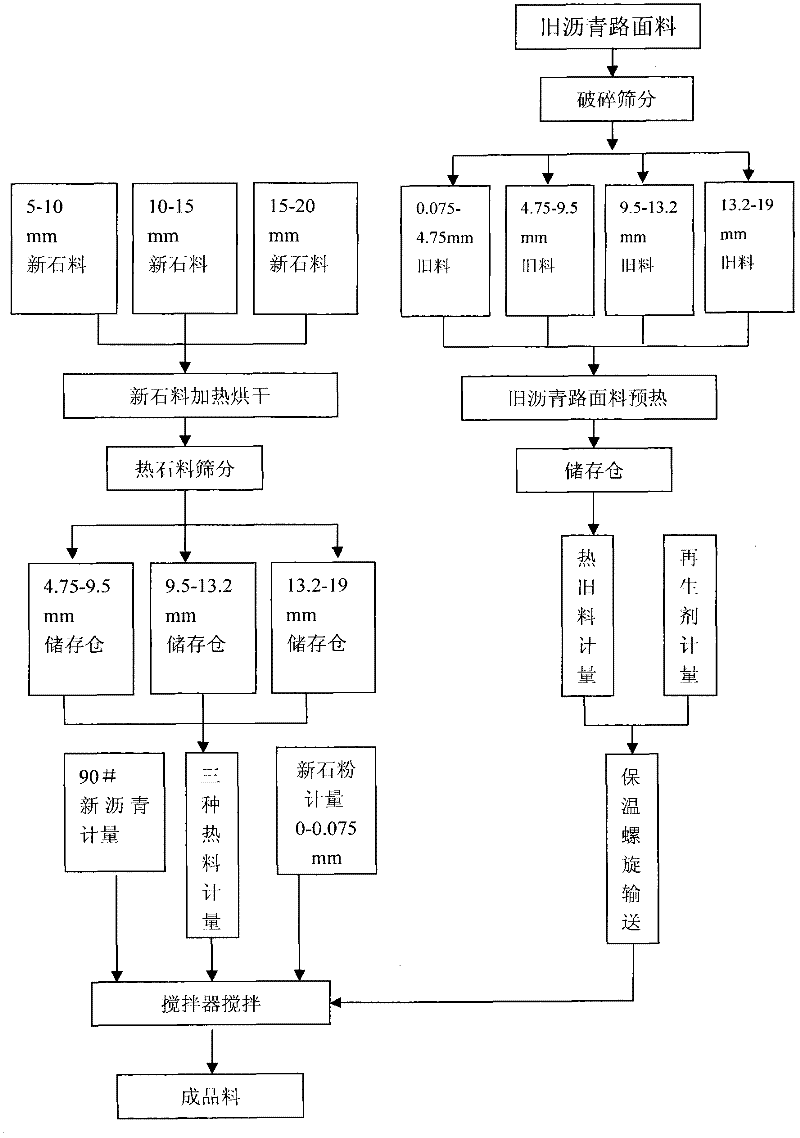

[0048] refer to figure 1 , a kind of asphalt pavement fabric production process based on thermal regeneration of asphalt pavement old material of the present invention, it comprises the thermal regeneration production step of asphalt pavement old material and the production step of new asphalt pavement material:

[0049] The thermal regeneration production steps of old asphalt pavement materials include:

[0050] 1) Collect old asphalt road fabrics and transport them to the mixing site for use;

[0051] 2) Use a loader to pour the collected old asphalt road fabric into the hopper of the crushing and screening equipment, and the vibrating feeder that has been crushed and screened will evenly feed the material to the jaw crusher for primary crushing, and the primary crushed material will be sent to the crusher through a belt conveyor. To the hammer crusher f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com