Furnace self-preheating oxygen-enriched burner with temperature-gathering type oxygen-enriched nozzle

An oxygen-enriched combustion and burner technology, which is applied to the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, etc., and can solve the combustion flame temperature The improvement is small, unable to support combustion, unfavorable for combustion, etc., to achieve the effect of reducing the combustion air volume, increasing the temperature of the combustion furnace, and improving the efficiency of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

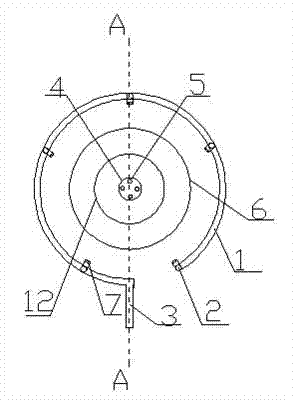

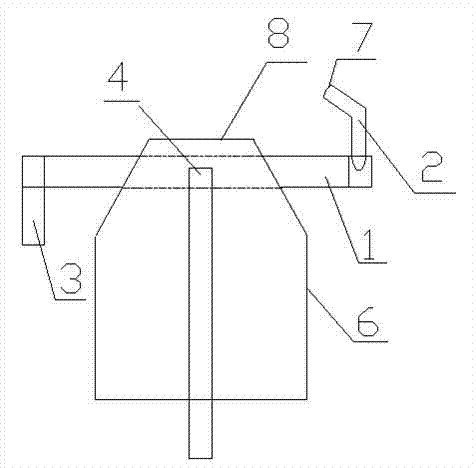

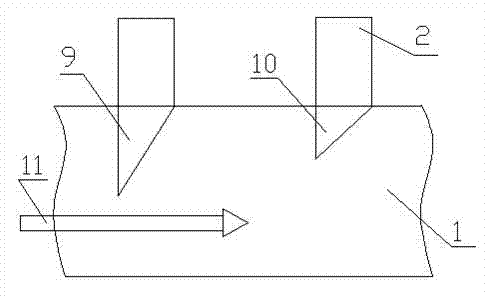

[0032] exist figure 1 In the embodiment shown in —4: the middle of the combustion-supporting air duct in the burner 6 gradually becomes smaller to the air outlet 12, and a plurality of swirl plates 13 are installed on the inner side of the smaller area, and the gradually smaller and band swirl plates 13 The combustion-supporting air duct of the burner 6 can make the combustion-supporting air entering from the air duct of the burner 6 have an inclination angle and swirl into the injected fuel flow at an angle of 10 degrees to 45 degrees to support combustion; the oxygen-enriched preheating pipe 1 in the furnace is surrounded by Around the burner 6 in the combustion furnace, it is attached or half-buried in the insulation layer around the burner 6, and the oxygen-enriched preheating pipe 1 in the furnace is welded with two or several oxygen-enriched nozzles distributed symmetrically with the burner 6 The pipe 2 and the oxygen-enriched nozzle 7 are connected to the oxygen-enriche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com