A plate heat exchanger and its application in seawater aquaculture

A technology of plate heat exchanger and seawater, which is applied in the direction of heat exchanger type, indirect heat exchanger, application, etc., can solve the problems of waste of resources, increase of breeding cost of seawater nursery households, etc., achieve less floor space and reduce labor intensity and the cost of the number of workers employed, and the effect of reducing harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

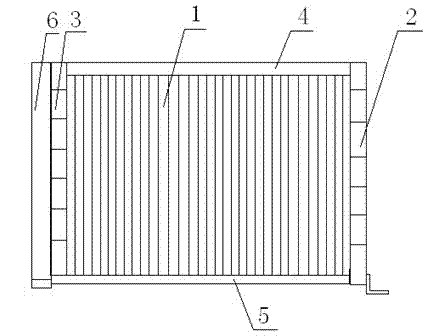

[0029] A plate heat exchanger, including a detachable frame, in which a plurality of heat exchange plates 1 are sequentially stacked, and the heat exchange plates 1 are sealed and pressed by sealing gaskets 11, and the heat exchange plates 1 The four corners are provided with corner holes 7 through which the heat exchange liquid passes, and the corresponding surfaces of two adjacent heat exchange plates 1 and the surrounding sealing gasket 11 between the two adjacent heat exchange plates 1 constitute a The heat exchange chamber is closed all around, and the heat exchange liquid passes through the heat exchange chamber through the corner hole 7 .

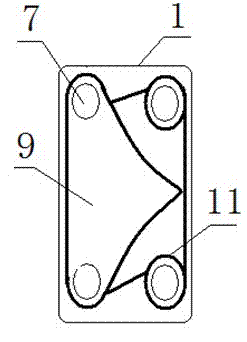

[0030] The form of the heat exchange chamber is as follows: two heat exchange spaces that are staggered with each other and pass through liquids of one temperature respectively. One heat exchange space is formed by sealing the sealing ring of the sealing gasket 11 to the left side of the heat exchange plate 1 in the vertical direction...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is that the structure of the heat exchange chamber is:

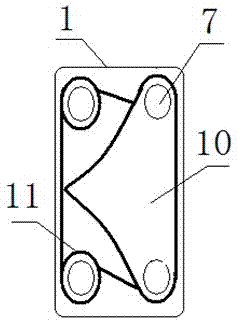

[0034] It is two heat exchange spaces spaced apart in the middle and respectively connected with a temperature liquid. One heat exchange space is formed by sealing the upper and lower corner holes 7 on the left side of the heat exchange plate 1 in the vertical direction by the sealing ring of the sealing gasket 11. The first heat exchange space 9 is surrounded and closed along the centerline of the heat exchange plate 1, and the other heat exchange space is formed by sealing the upper and lower corners of the vertical right side of the heat exchange plate 1 by the sealing ring of the gasket 11. The hole 7 surrounds and closes the second heat exchange space 10 along the centerline of the heat exchange plate 1 ; the first heat exchange space 9 and the second heat exchange space 10 are respectively formed on the same surface of the heat exchange plate 1 .

Embodiment 3

[0036] The difference between this embodiment and Embodiment 2 is that the structure of the heat exchange chamber is: on the basis of the second configuration form of the heat exchange chamber, the first heat exchange space 9 or the second heat exchange space 10 will be formed, surrounding and along the The sealing ring of the sealing gasket 11 closed in the centerline direction of the heat exchange plate 1 extends to the right or left, and the right or left extension is the first heat exchange space 9 and the second heat exchange space 10 along the heat exchange plate. 1 stacked staggered to extend to the other side.

[0037] Specifically, it is two heat exchange spaces that are staggered with each other and respectively penetrate a temperature liquid. One heat exchange space is formed by sealing the upper and lower corners on the left side of the heat exchange plate 1 in the vertical direction by the sealing ring of the sealing gasket 11. The hole 7 surrounds and extends to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com