Film attachment equipment for light guide plate

A light guide plate and film material technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as great differences in attachment quality and attachment speed, injuries to personnel's finger skin and wrists, and high turnover rate of personnel. Economic benefits and market competitiveness, stable quality, and simplified inventory management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

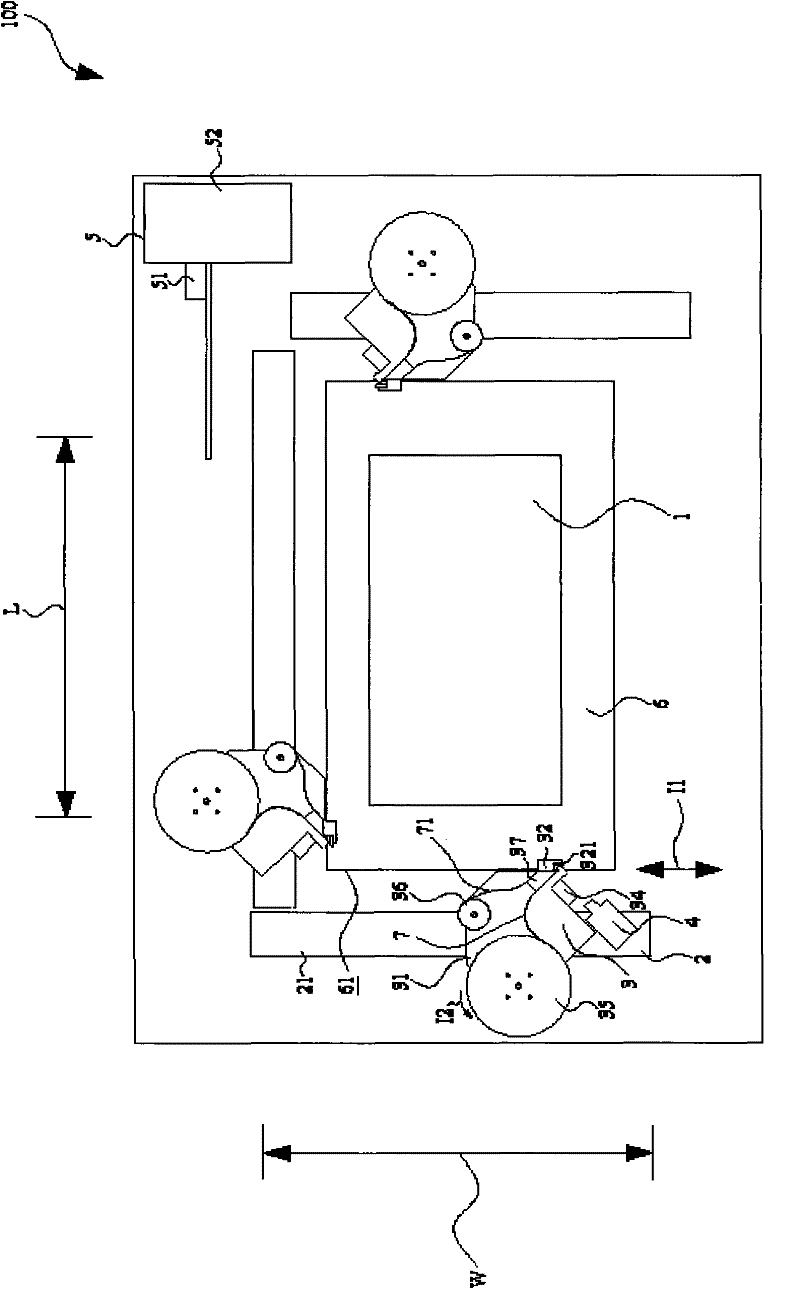

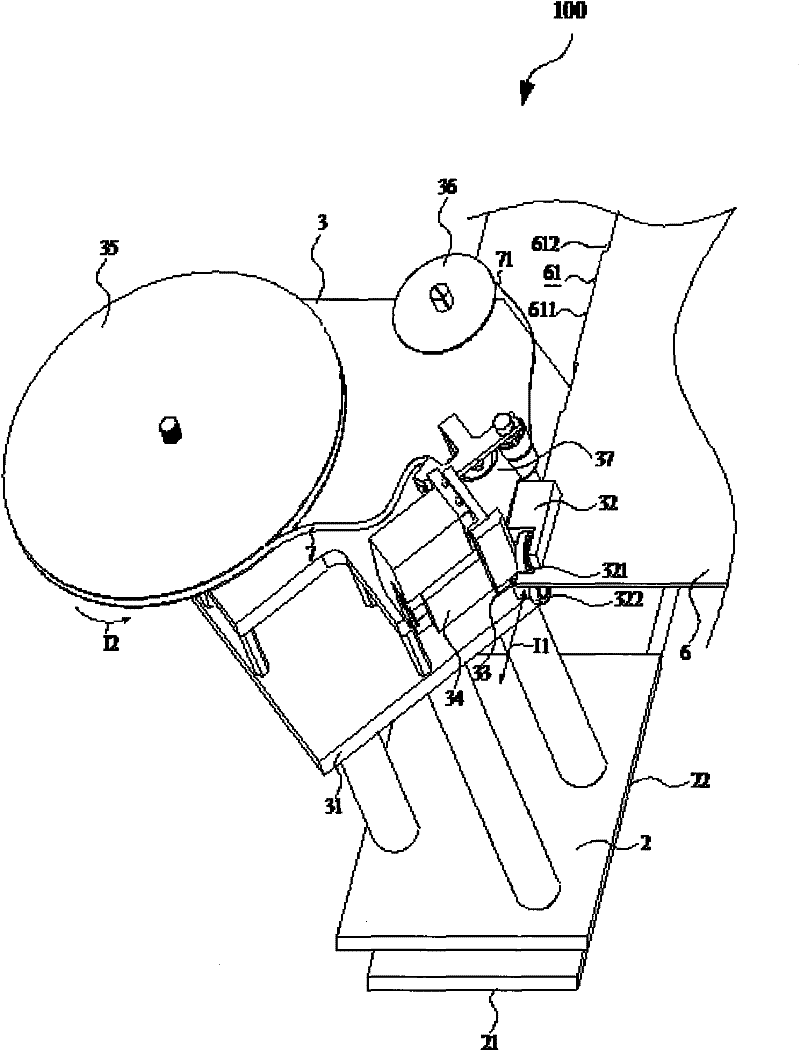

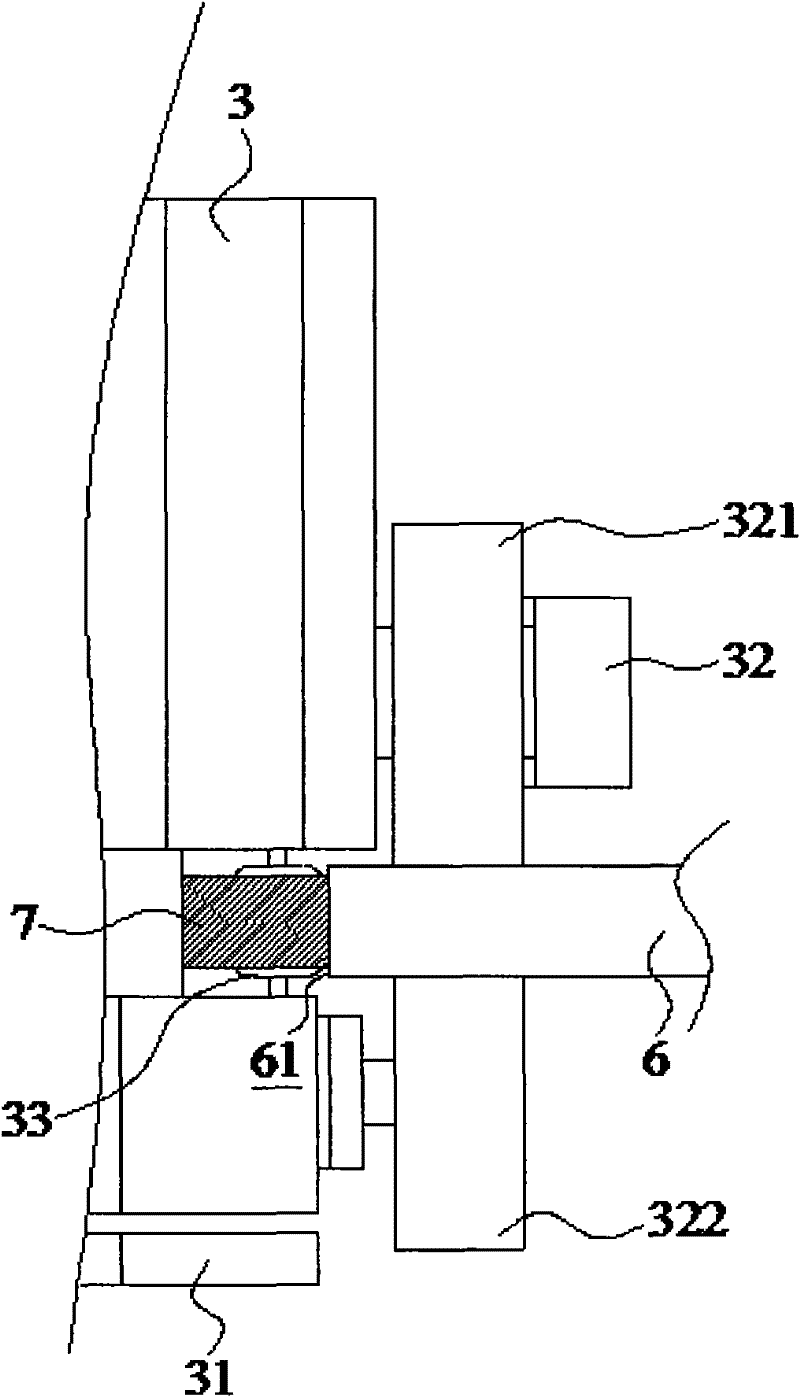

[0041] refer to figure 1 as shown, figure 1 It is a perspective view showing the film sticking equipment of the light guide plate of the present invention. The film attaching device 100 for the light guide plate of the present invention includes a supporting mechanism 1 , a sliding mechanism 2 , a film attaching mechanism 3 , a position sensing device 4 and an attaching device controller 5 . The supporting mechanism 1 can be used to support one or more light guide plates 6 , and the three sides of the supporting mechanism 1 are respectively provided with a sliding mechanism 2 and a film attaching mechanism 3 . The light guide plate 6 is placed in the supporting mechanism 1 , and the light guide plate 6 is fixed on the supporting mechanism 1 through alignment and vacuum adsorption without being moved by external force.

[0042] In this embodiment, the thickness surface of the light guide plate 6 is defined as a film attaching surface 61, and the film attaching surfaces 61 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com