How to make soundproofing material

A technology of sound-insulating materials and manufacturing methods, applied in the direction of sound insulation, insulation layer, sound-generating equipment, etc., can solve problems such as inconvenience, achieve the effects of eliminating noise and/or vibration, improving cushioning, and improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, a method for manufacturing a sound-insulating material according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings. The provided drawings are used to illustrate the embodiments of the present invention, and are only used to explain the present invention in more detail, and do not limit the technical scope of the present invention thereby.

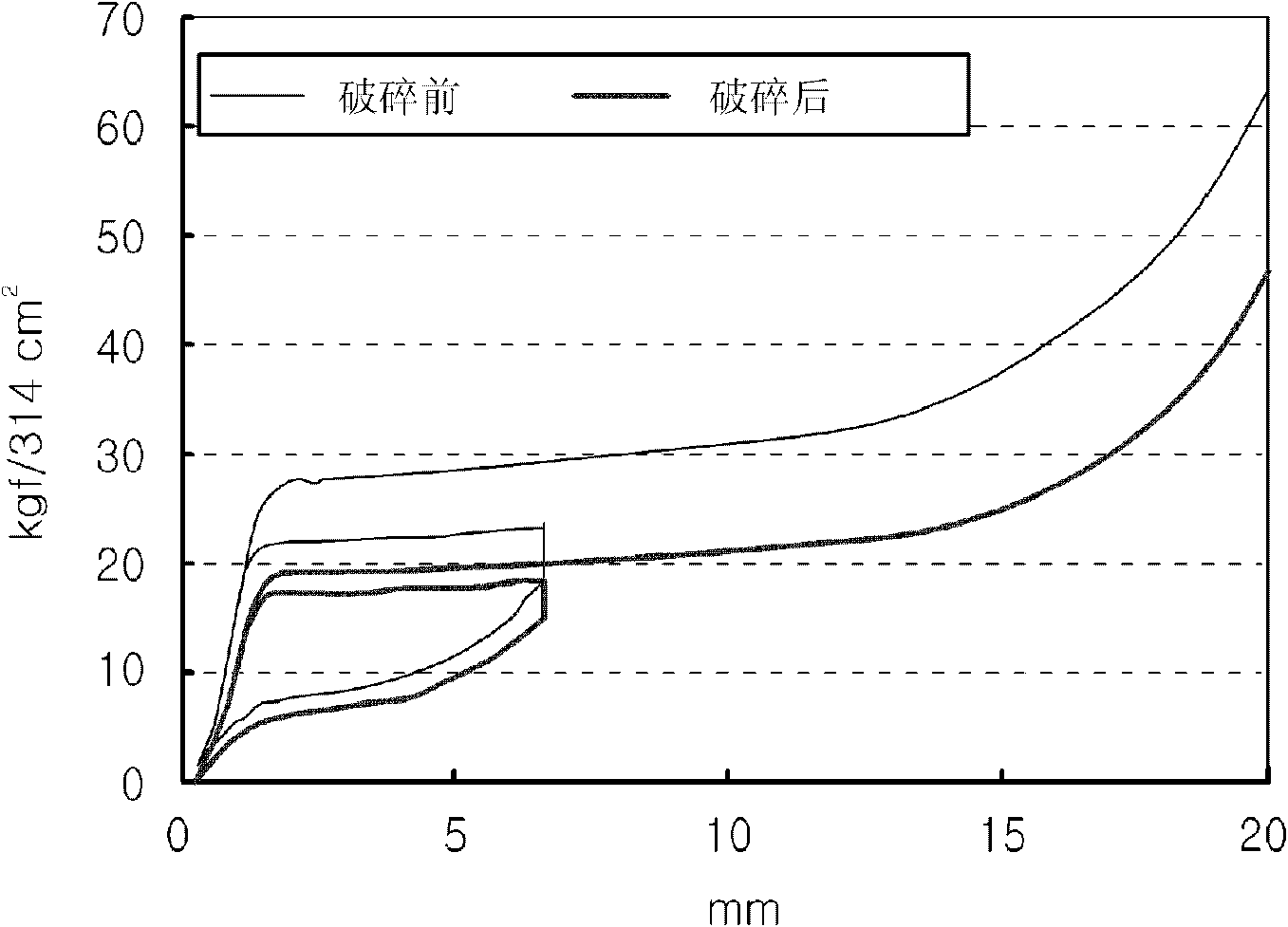

[0014] The present invention relates to a method for manufacturing a sound-insulating material comprising resin foamed foam containing open cells and closed cells. The step of crushing the closed chamber (hereinafter referred to as "crushing process").

[0015] The term "open cells" used in the present invention is the microcells contained in the foamed foam, including all microcells with at least a part of openness (open), and the "open cell rate" means that the volume of open cells in the foamed foam The proportion of the volume of the entire micropore. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com