Method for patterning nanoscale patterns of molecules on material surfaces

A nanoscale, molecular technology for use in the field of probe-based methods that can solve problems such as difficulty in obtaining retention times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

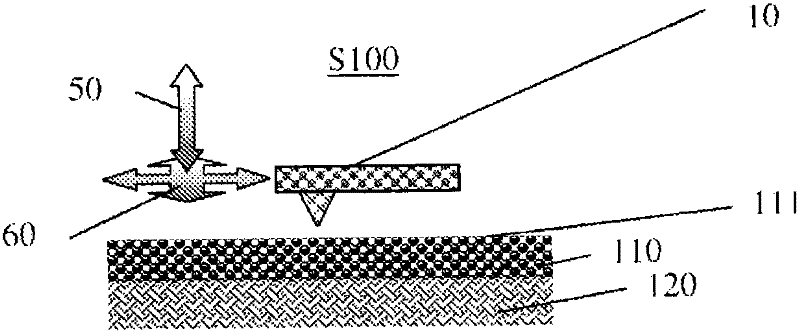

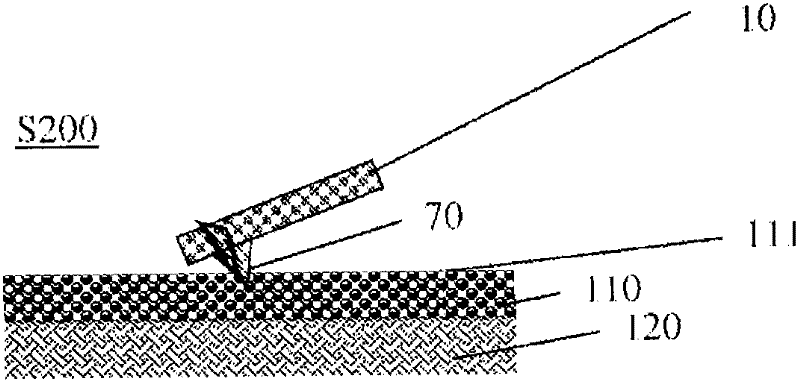

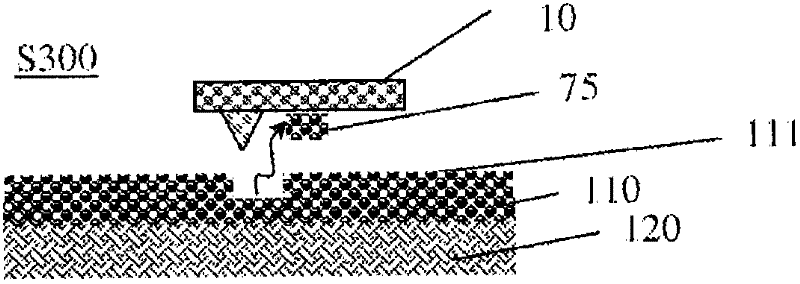

[0025] As an introduction to the following description, embodiments described herein relate to methods for patterning the surface of a material. In one embodiment, a material having a polymer film thereon is provided. The probes are then used to create patterns on the membrane by desorbing molecules at the membrane surface.

[0026] The membrane comprises a network of molecules cross-linked via intermolecular non-covalent bonds such as van der Waals forces or hydrogen bonds. More specifically, the nature of such bonds is not covalent (at least not primarily), ie there is no definite electron pairing between the atomic groups that characterizes ordinary Heitler-London covalent bonds. In contrast, the interaction energy of weak intermolecular bonds can be divided into various physically meaningful components, such as electrostatic, exchange, dispersion, relaxation, etc. However, none of the above components can be definitively called "covalent", since anti-bonding mixing of at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com