Water jet propulsion body for ships

A mixed-flow, ship technology, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of simple structure, unoptimized functions, no propulsion utility, etc., to improve propulsion power and propulsion efficiency, propulsion power and propulsion efficiency. The effect of improving and reducing wave-making resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

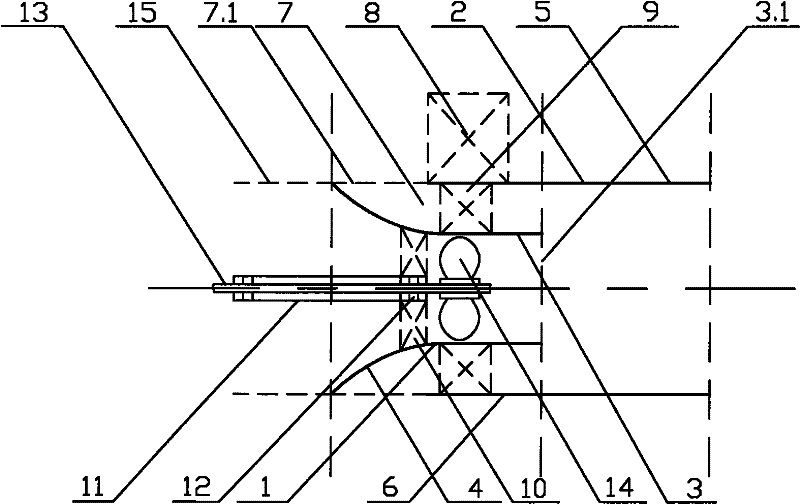

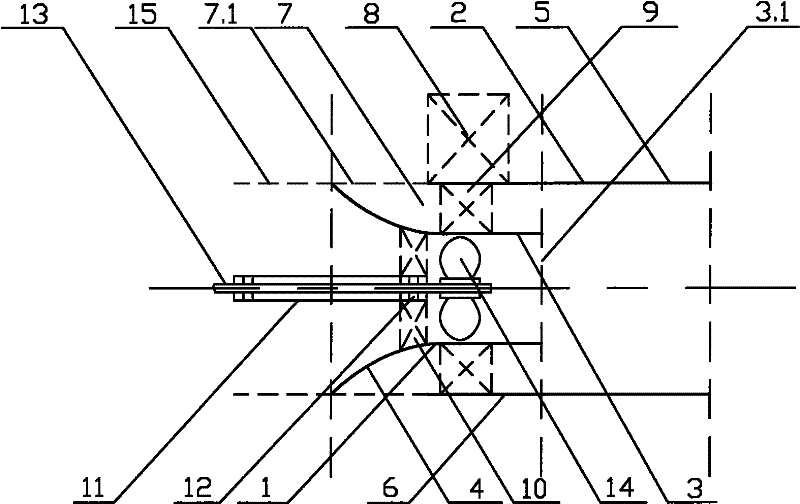

[0030] Such as figure 1 As shown, the water-jet mixed-flow propulsion body of the ship is mainly composed of a conduit 1 and a casing 2, and the conduit 1 extends into the casing 2 to form a flow mixer. The outlet portion of the conduit 1 is a jet tube 3 , the inlet portion of the conduit 1 is a bell mouth 4 , and the outer edge of the bell mouth 4 is in contact with the outer surface of the casing 2 . The sleeve pipe 2 is divided into two parts by the water spray port 3.1 of the jet pipe 3 , the outlet part is the mixed flow pipe 5 , and the inlet part is the follower pipe 6 . The outer wall surface of the conduit 1 and the tracer pipe 6 together form the tracer passage 7, and between the outer edge of the bell mouth 4 and the front end of the tracer pipe 6 is the water inlet of the tracer passage 7 and its grille 7.1. The outer wall surface of sleeve pipe 2 has body support 8, is connected and fixed with hull. There is a pipe bracket 9 between the sleeve pipe 2 and the cat...

Embodiment 2

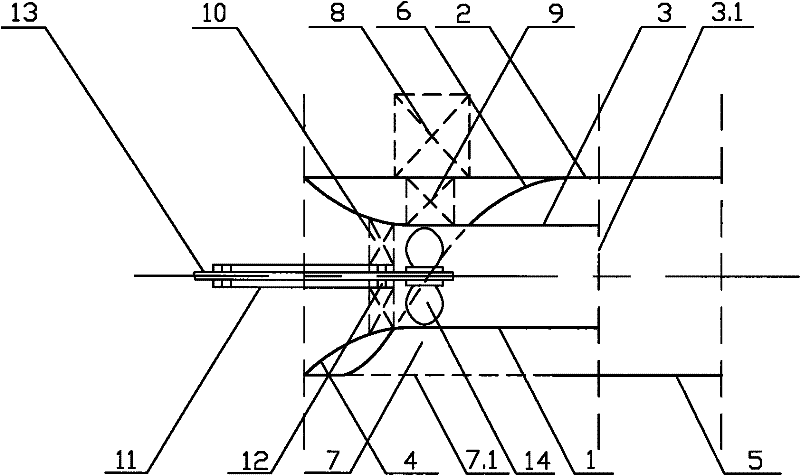

[0034] Such as figure 2 As shown, the water-jet mixed-flow propulsion body of the ship is mainly composed of a conduit 1 and a casing 2, and the conduit 1 extends into the casing 2 to form a flow mixer. The outlet part of the conduit 1 is a jet tube 3 , and the inlet part of the conduit is a bell mouth 4 . The outer edge of the bell mouth 4 is in contact with the outer wall of the casing 2, and the water inlet of the follower channel 7 and its grille 7.1 are arranged on the outer wall of the casing 2. The casing 2 is divided into two parts by the water spray port 3.1 of the jet pipe 3, and its outlet part is a mixed flow pipe 5, which communicates with the accompanying flow channel 7. The follower channel 7 is formed solely by the follower pipe 6 which has an elbow 6.1 through which the conduit 1 passes. The outer wall surface of sleeve pipe 2 has body support 8, is connected and fixed with hull. There is a pipe bracket 9 between the sleeve pipe 2 and the catheter 1 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com