Assembly type rotating target apparatus facilitating changing of target materials

A component type, rotating target technology, applied in the field of easy-change target component type rotating target device, can solve the problems of target component replacement, affect processing effect and service life, target installation position gap, etc., to improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

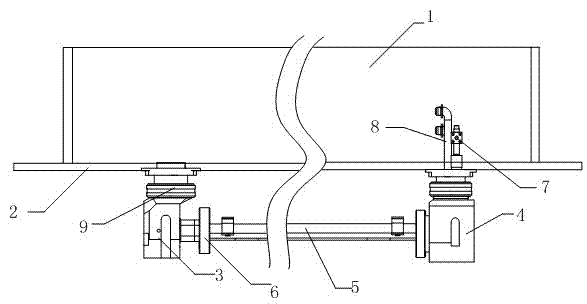

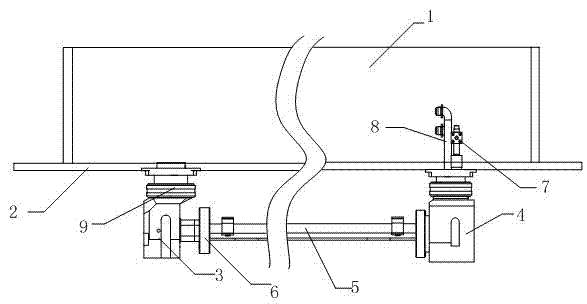

[0012] Such as figure 1 The shown rotating target device of easy-change target assembly 5 includes a processing box 1, and a bottom plate 2 is arranged at the bottom of the processing box 1. Terminal assembly 3. Correspondingly, a hydropower terminal assembly 4 is installed on the other side of the bottom plate 2 . A target assembly 5 is installed in the working connecting end of the driving end assembly 3 and the hydropower end assembly 4 .

[0013] In view of a preferred embodiment of the present invention, in order to adapt to different lengths and types of target assemblies 5, it can be stably installed in the working connection end of the drive end assembly 3 and the hydropower end assembly 4, at the drive end The working connection ends of the component 3 and the hydropower terminal component 4 are all provided with telescopic shaft retaining rings 6 . In this way, in actual use, the telescopic length of the telescopic retaining ring 6 for the shaft can be adjusted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com