Earthquake-resistant energy-saving insulation brick

A technology of thermal insulation bricks and thermal insulation materials, applied in the direction of building materials, etc., can solve the problems of easy damage, lack, poor thermal insulation performance, etc., and achieve the effects of good shear bearing capacity, good thermal insulation performance, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

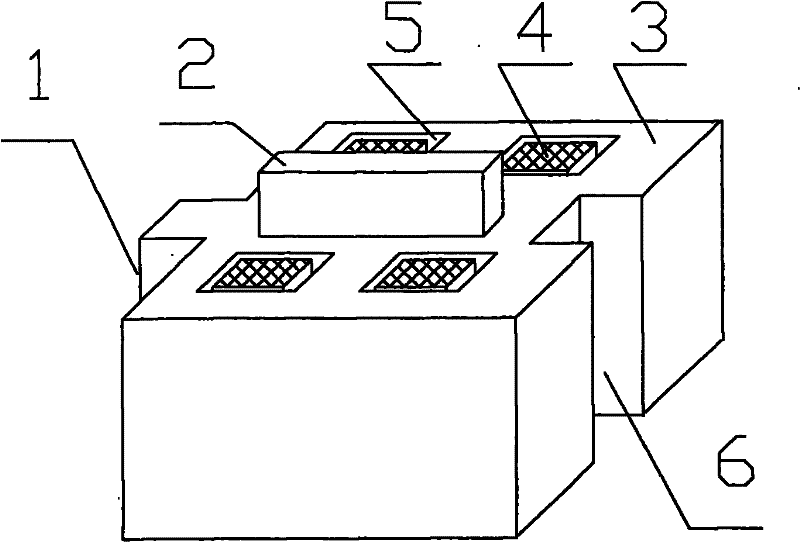

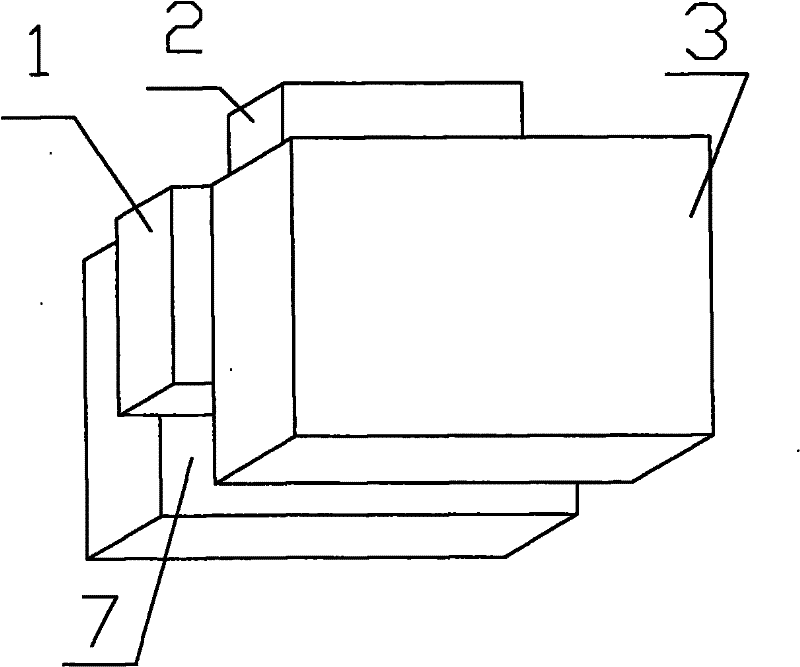

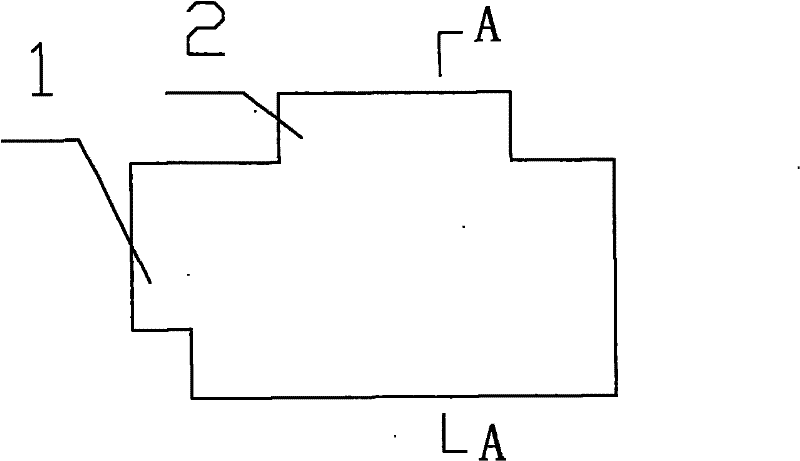

[0029] See attached figure 1 , 2 , 3, 4, the anti-seismic energy-saving thermal insulation brick shown in the first embodiment of the present invention includes a brick body 3, the middle part of the upper end face of the brick body 3 is provided with a cuboid top tenon, and the middle part of the lower end face of the brick body corresponds to At the position of the above-mentioned top tenon, there is a bottom concave long groove 7 that can fit the above-mentioned tenon. One end surface of the brick body is provided with a rectangular parallelepiped tenon 1, and the other end surface of the brick body is provided with the above-mentioned side. The corresponding position of the tenon is a lateral groove 6 that can be fitted with the above-mentioned lateral tenon. The centers of the longitudinal tenon, the longitudinal groove, the lateral tenon and the lateral groove are located in the same plane. There are two rows of rectangular longitudinal blind holes 5, the longitudinal h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com