Sea sand concrete bending member

A flexural member and concrete technology, applied in truss-type structures, joists, girders, etc., can solve the problems that sea sand cannot be effectively utilized as resources, the prospects for industrialized production are not obvious, and the overall bearing capacity of the structure is reduced. Excellent bending performance, sufficient stress and deformation, and improved shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

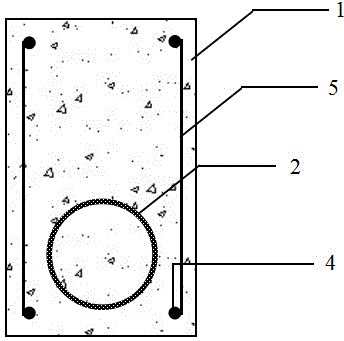

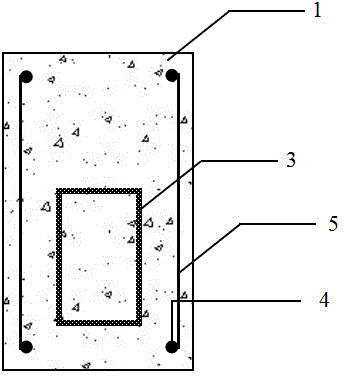

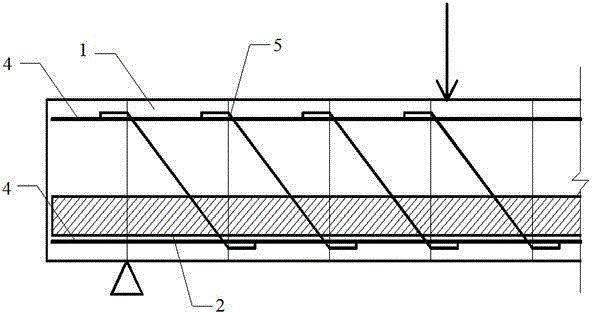

[0023] The structure diagram of the present invention is as figure 1 , 2 , 3, the sea-sand concrete flexural member of the present invention includes sea-sand concrete 1, FRP longitudinal reinforcement 4, and sea-sand concrete 1 is provided with FRP longitudinal reinforcement 4 arranged along the length direction of the bending member and is provided with The FRP transverse reinforcement arranged along the width direction of the flexural member, the FRP longitudinal reinforcement 4 and the FRP transverse reinforcement are tied together to form a member reinforcement skeleton through connectors, and an FRP pipe is arranged eccentrically in the sea-sand concrete 1. In this embodiment, the FRP pipe is set The ductility of sea-sand concrete elements can be improved at locations close to the tension zone.

[0024] In this embodiment, the above-mentioned FRP pipes are FRP round pipes 2 or FRP square pipes 3 . The cross-sectional shape of the above-mentioned sea-sand concrete flex...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the above-mentioned FRP transverse bars are FRP stirrups 6 , and the FRP longitudinal bars 4 are bound to the FRP stirrups 6 through connectors to form a member reinforcement skeleton. The above-mentioned FRP stirrup 6 is an FRP bar bent into a square or a circle. The cross-sectional shape of the sea-sand concrete flexural member along the width direction is rectangular or circular, Figure 4 , Figure 5 Shown is a rectangular cross-section, Figure 6 Shown in circular cross-section. and Figure 4 It is shown that the FRP pipe eccentrically arranged in the sea sand concrete 1 is a FRP round pipe 2, Figure 5 It is shown that the FRP pipe eccentrically arranged in the sea-sand concrete 1 is an FRP square pipe 3 . Such as Figure 6 It is shown that the FRP pipe eccentrically arranged in the sea sand concrete 1 is an FRP circular pipe 2 . Figure 7 Shown is a schematic diagram of binding FRP stirrups 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com