Locally-embedded steel pipe concrete column type aseismatic bridge pier

A steel tube concrete column and concrete technology, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of bridge piers losing vertical bearing capacity, bridge loss of use function, bridge piers and bridges cannot be repaired, etc., to avoid shear damage and bending Effects of crushing, improving seismic safety, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

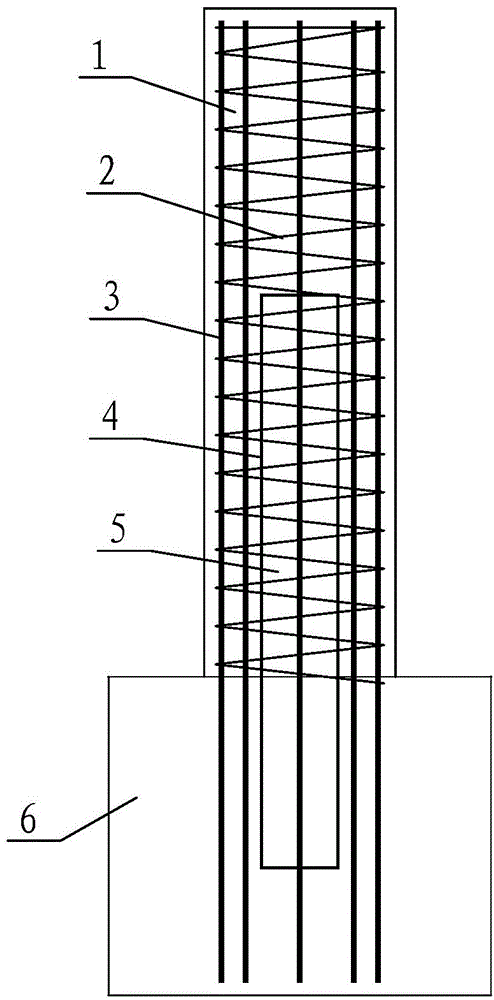

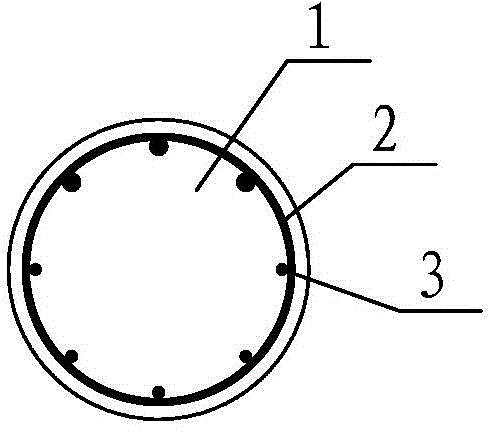

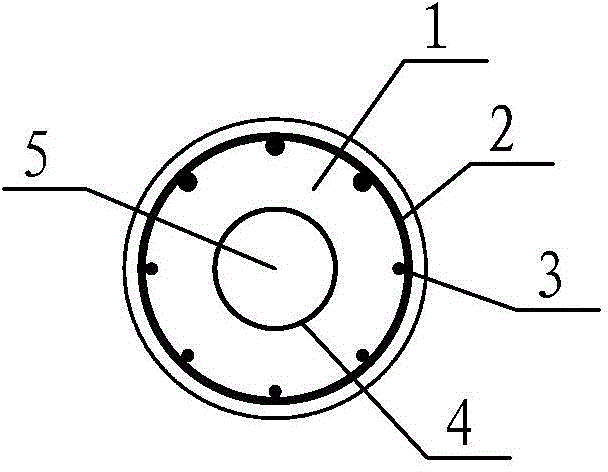

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0017] The reinforced concrete piers of the bridges are provided with a reinforced concrete foundation 6, which generally adopts a rectangular enlarged foundation, a pile foundation with a circular cross section or a cap on a pile foundation. Before pouring the concrete of the foundation 6, a part of the length of the longitudinal reinforcement 3 and the steel pipe 4 is pre-embedded below the top surface of the foundation, and then the concrete of the foundation 6 is poured.

[0018] After the concrete of the foundation 6 reaches the design strength, the steel pipe 4 is filled with high-strength concrete 5 .

[0019] Stirrups 2 are arranged outside the longitudinal bars 3, and the stirrups 2 are positioned on the longitudinal bars 3 by wrapping steel wires at a certain interval.

[0020] A formwork is set outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com