Color filter and manufacturing method thereof

A color filter and color layer technology, which is applied in the fields of optical filters, optics, nonlinear optics, etc., can solve the problems of contrast reduction and pixel light leakage, and achieve the effects of increasing panel contrast, simplifying the production process, and improving light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the invention are discussed in more detail below. However, this embodiment may be an application of various inventive concepts, and may be embodied in various specific ranges. The specific embodiments are for illustrative purposes only and do not limit the scope of the disclosure.

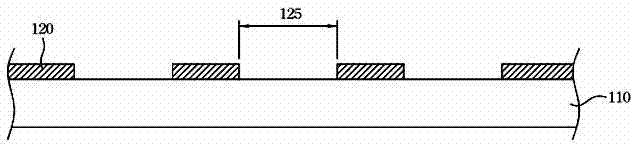

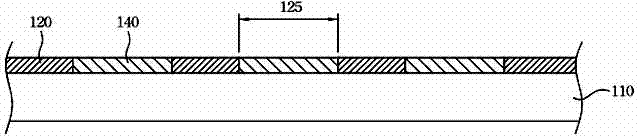

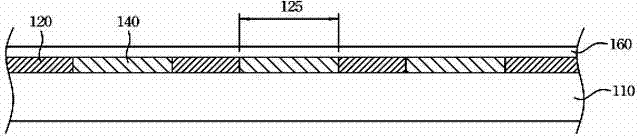

[0033] Please refer to Figures 2A-2D , which shows a schematic cross-sectional structural view of a color filter manufacturing method in different manufacturing steps according to an embodiment of the present invention. Please refer to Figure 2A , forming a plurality of first black matrices 220 a and a plurality of second black matrices 220 b on the substrate 210 . Wherein, black matrix material can be formed on the substrate, and then a plurality of first black matrix 220a, second black matrix 220b and sub-pixel intervals 225 can be defined by using lithography and etching process. In this embodiment, the first black matrix 220a and the second black matrix 220b are man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com